Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Slotter Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Slotter Operator so you can tailor your answers to impress potential employers.

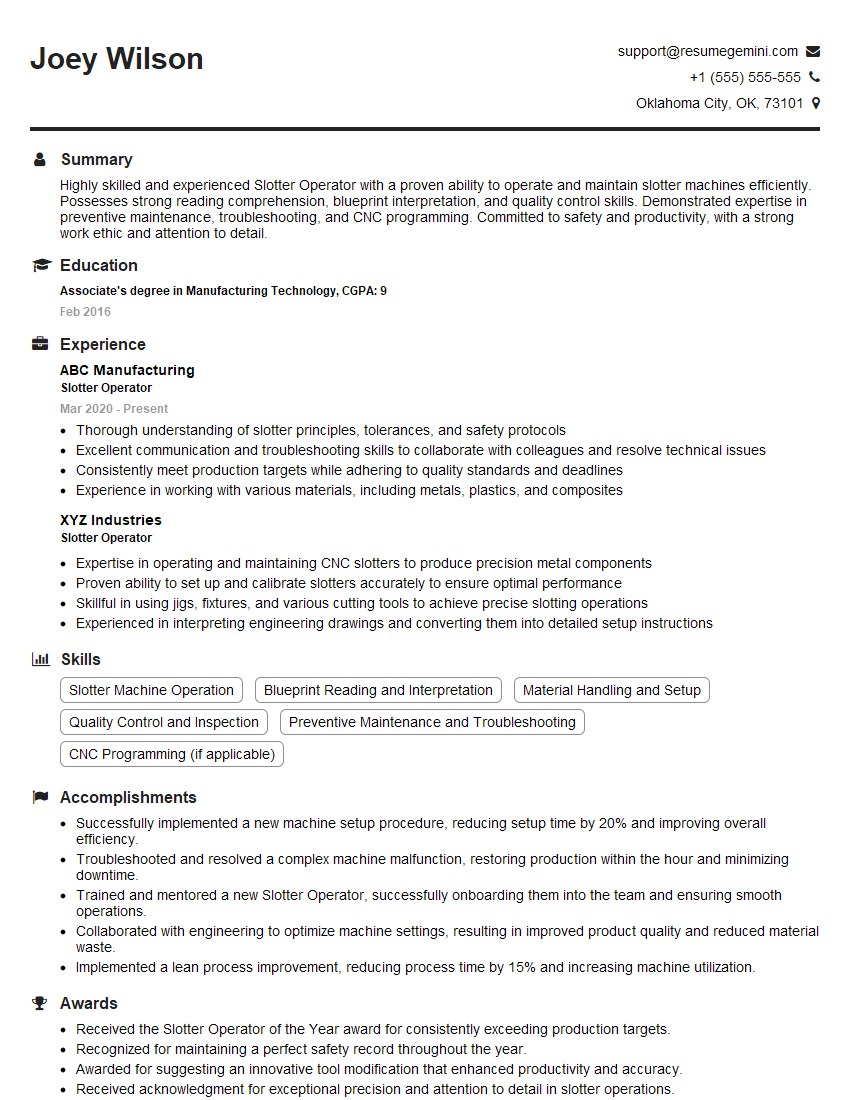

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slotter Operator

1. Describe the process of setting up a slotter machine?

Setting up a slotter machine involves the following steps:

- Mount the workpiece on the machine table and secure it using clamps or fixtures.

- Select and install the appropriate cutting tool (slotting tool) into the machine spindle.

- Set the machine parameters, including the cutting speed, feed rate, and depth of cut.

- Align the cutting tool with the workpiece and adjust the machine’s position to ensure proper cutting action.

- Start the machine and monitor the cutting process, making any necessary adjustments as required.

2. What are the different types of slotting operations and how do they differ?

Internal slotting:

- Creates slots or keyways within the workpiece, typically used for fitting shafts or keys.

- Requires the use of a slotting saw or end mill.

External slotting:

- Cuts slots or grooves on the outer surface of the workpiece, such as for mounting components or creating channels.

- Uses a slotting tool or end mill with a suitable geometry for external cutting.

Curvilinear slotting:

- Creates curved slots or irregular shapes in the workpiece.

- Requires the use of a slotting tool with a special shape or a CNC-controlled machine.

Gang slotting:

- Simultaneously cuts multiple slots or grooves in the workpiece.

- Uses a slotting head with multiple cutting tools, allowing for increased productivity.

3. How do you calculate the cutting speed and feed rate for a slotter operation?

The cutting speed and feed rate for a slotter operation can be calculated using the following formulas:

- Cutting Speed (Vc) = (π * Spindle Speed * Tool Diameter) / 1000

- Feed Rate (Fr) = (Cutting Speed * Number of Teeth) / 60

- Where Spindle Speed is in RPM, Tool Diameter is in mm, and Number of Teeth is the number of teeth on the cutting tool.

4. What are the safety precautions to observe when operating a slotter machine?

When operating a slotter machine, it is crucial to prioritize safety by adhering to the following precautions:

- Wear appropriate safety gear, including safety glasses, gloves, and appropriate clothing.

- Securely clamp the workpiece and ensure it is stable before starting the machine.

- Keep hands and loose clothing away from the cutting area.

- Use sharp cutting tools to minimize force and avoid accidents.

- Be aware of the machine’s surroundings and potential hazards.

- Follow proper machine operating procedures and do not override safety features.

5. How do you maintain a slotter machine for optimal performance and longevity?

Maintaining a slotter machine for optimal performance and longevity involves the following practices:

- Regularly clean and lubricate the machine components, including the spindle, table, and slides.

- Inspect and replace cutting tools as needed to ensure sharpness and avoid dull tools.

- Check and adjust the machine’s alignment and backlash to maintain precision.

- Monitor the machine’s performance and make adjustments to cutting parameters as necessary.

- Follow the manufacturer’s recommended maintenance schedule and consult with qualified technicians for any repairs or complex maintenance tasks.

6. Describe the different types of cutting fluids used in slotter operations and their applications.

Various cutting fluids are used in slotter operations, each with specific applications:

- Soluble Oils: Water-based emulsions used for cooling and lubrication, suitable for general-purpose slotting.

- Straight Oils: Mineral oils used for demanding operations, providing good lubrication and heat dissipation.

- Synthetic Fluids: Advanced fluids designed for specific applications, offering extended tool life and enhanced performance.

- Cryogenic Fluids: Liquid nitrogen or carbon dioxide used in high-speed slotting operations for improved cooling and reduced tool wear.

7. What are the common defects that can occur in slotter operations and how can they be prevented?

Common defects in slotter operations include:

- Burrs: Sharp edges left on the workpiece due to improper tool selection or dull tools. Prevented by using sharp tools and correct cutting parameters.

- Chatter: Vibrations during cutting, resulting in a rough surface finish. Prevented by ensuring proper workpiece clamping, sharp tools, and balanced cutting parameters.

- Tool Breakage: Occurs due to excessive force or improper tool selection. Prevented by using the correct tool for the material and cutting operation.

- Dimensional Errors: Inaccurate slot dimensions due to machine misalignment or incorrect tool setup. Prevented by regular machine calibration and precise tool positioning.

- Overheating: Excessive heat buildup can damage the workpiece and tool. Prevented by using appropriate cutting fluids, maintaining correct cutting parameters, and avoiding prolonged cutting.

8. How do you troubleshoot common problems encountered with slotter machines?

Troubleshooting common slotter machine problems involves the following steps:

- Identify the problem and its symptoms.

- Check for loose connections, worn parts, or incorrect settings.

- Verify the cutting tool is sharp and properly secured.

- Inspect the workpiece for proper clamping and alignment.

- Review the cutting parameters and adjust as needed.

- Consult the machine manual or seek assistance from qualified personnel if necessary.

9. Describe the different types of materials that can be slotted using a slotter machine.

Slotter machines can be used to slot a wide range of materials, including:

- Metals: Ferrous and non-ferrous metals, such as steel, aluminum, and brass.

- Plastics: Various types of plastics, including acrylic, polycarbonate, and nylon.

- Wood: Soft and hardwood species.

- Composites: Materials like fiberglass-reinforced plastics and carbon fiber composites.

- Other materials: Graphite, ceramics, and certain alloys.

10. How do you calculate the power required for a slotter operation?

The power required for a slotter operation can be calculated using the following formula:

- Power (P) = (Cutting Force * Cutting Speed) / 60000

- Where Cutting Force is in Newtons and Cutting Speed is in meters per minute.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slotter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slotter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A slotter operator is responsible for operating and maintaining slotting machines in various mechanical and manufacturing environments. The primary job responsibilities include:

1. Machine Operation

Setting up, operating, and monitoring slotting machines to produce workpieces according to specifications.

- Installing and aligning cutting tools and workpieces correctly.

- Adjusting machine settings and feeds and speeds to optimize quality and efficiency.

2. Quality Control

Inspecting and measuring workpieces to ensure they meet quality standards and specifications.

- Using measuring tools and gauges to check dimensions, tolerances, and surface finishes.

- Identifying and correcting defects or errors in the slotting process.

3. Machine Maintenance

Performing routine maintenance and repairs on the slotting machines.

- Cleaning, lubricating, and inspecting machines for wear or damage.

- Replacing or repairing worn or defective parts as needed.

4. Material Handling

Loading and unloading workpieces and materials into and out of the slotting machines.

- Using cranes, forklifts, or other equipment to move heavy materials safely.

- Following safety procedures and ensuring proper handling of materials.

Interview Tips

To ace a job interview for a Slotter Operator position, follow these tips:

1. Research the Company and Position

Learn about the company’s history, industry focus, and products or services. Understand the specific requirements and expectations for the Slotter Operator role.

- Visit the company website, LinkedIn page, and other online resources.

- Review the job description carefully to identify key responsibilities and qualifications.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating slotting machines and related equipment. Showcase your skills in quality control, machine maintenance, and material handling.

- Quantify your accomplishments whenever possible using specific numbers and metrics.

- Provide examples of how you have improved efficiency or reduced downtime in previous roles.

3. Demonstrate Safety Awareness

Stress your commitment to safety in the workplace. Share your knowledge of safety procedures and practices related to operating slotting machines.

- Describe your experience using proper personal protective equipment (PPE).

- Explain how you handle and dispose of hazardous materials safely.

4. Show Enthusiasm and Passion

Convey your interest in the Slotter Operator position and the mechanical or manufacturing industry. Express your eagerness to learn and contribute to the team.

- Share your previous experience with similar machines or processes.

- Explain why you are passionate about this field and why you want to join this company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slotter Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.