Are you gearing up for a career in Slubber Hand? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Slubber Hand and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

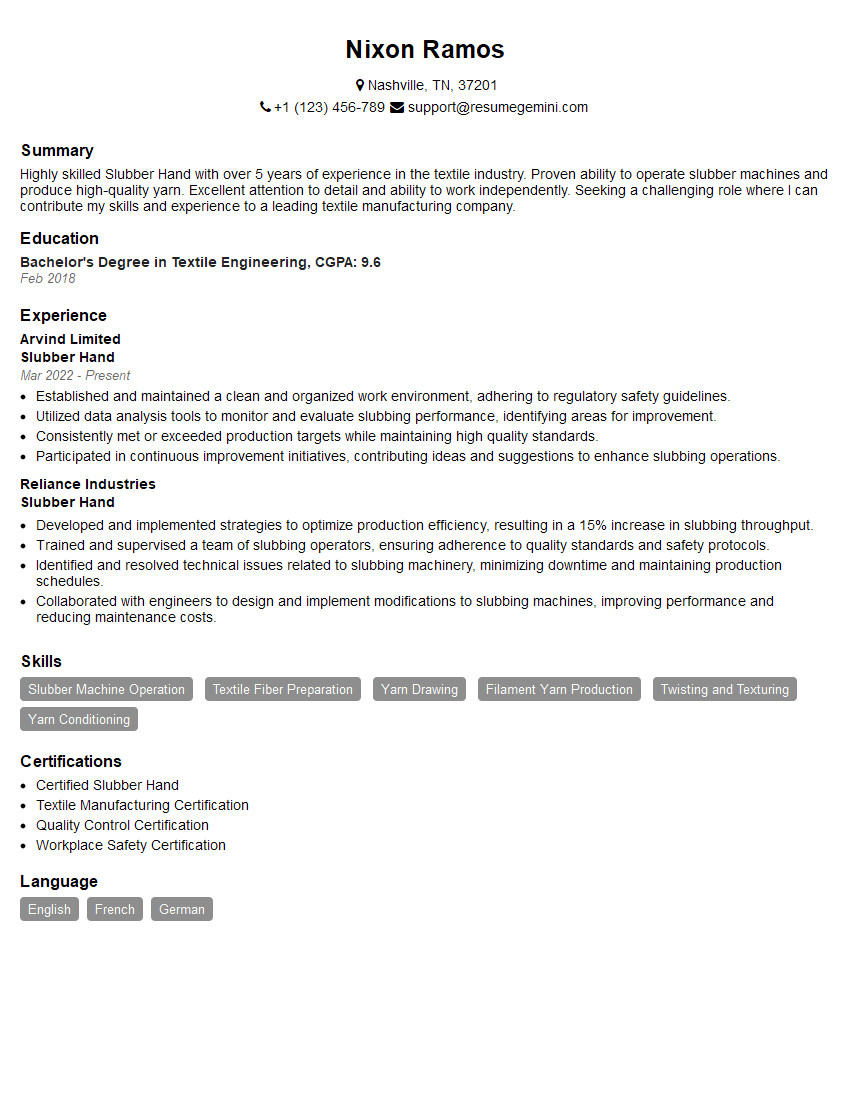

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slubber Hand

1. Explain the process of preparing a slub yarn in brief?

The process of preparing slub yarn involves several steps, including:

- Spinning the base yarn: The first step is to spin the base yarn, which will form the foundation of the slub yarn.

- Inserting slubs: Slubs are created by introducing thick or uneven sections into the base yarn. This can be done through various methods, such as using a slubbing attachment on a spinning machine or manually inserting slubs during spinning.

- Twisting the yarn: Once the slubs have been inserted, the yarn is twisted to give it strength and cohesion.

- Conditioning the yarn: The yarn is then conditioned to stabilize its moisture content and improve its handle.

2. Describe the factors that influence the appearance of slub yarn.

Fiber type and length

- The type and length of the fibers used can impact the appearance of the slub yarn. For instance, longer fibers produce smoother slubs, while shorter fibers create more pronounced slubs.

Slub size and spacing

- The size and spacing of the slubs can significantly alter the yarn’s appearance. Smaller, more closely spaced slubs create a subtle slub effect, while larger, more widely spaced slubs produce a more dramatic effect.

Twist level

- The amount of twist applied to the yarn can affect the definition of the slubs. Higher twist levels result in more defined slubs, while lower twist levels create softer, less pronounced slubs.

Dyeing and finishing

- Dyeing and finishing processes can also influence the appearance of slub yarn. Dyeing can enhance the contrast between the slubs and the base yarn, while finishing treatments can alter the texture and handle of the yarn.

3. Discuss the advantages and disadvantages of using slub yarns in textile manufacturing.

Advantages:

- Add visual interest and texture: Slub yarns introduce visual interest and texture to fabrics, making them stand out from ordinary yarns.

- Create unique effects: Slub yarns can be used to create unique effects such as slubbed denim, slubbed knits, and slubbed tweeds.

- Enhance fabric properties: Slub yarns can improve the drape, breathability, and moisture-wicking properties of fabrics.

Disadvantages:

- More expensive: Slub yarns are generally more expensive to produce than regular yarns due to the additional processing steps involved.

- Weaker: The presence of slubs can weaken the yarn, making it more susceptible to breakage.

- More difficult to work with: Slub yarns can be more challenging to work with during knitting, weaving, or crocheting due to their uneven texture.

4. Explain the different methods used to create slub yarns.

- Mechanical slubbing: This method uses a slubbing attachment on a spinning machine to introduce thick or uneven sections into the yarn.

- Manual slubbing: This method involves manually inserting slubs into the yarn during spinning.

- Chemical slubbing: This method uses chemical treatments to create weak spots in the yarn, which are then broken to form slubs.

- Air-jet slubbing: This method uses an air jet to create slubs in the yarn.

5. Describe the different types of slub yarns based on their appearance.

- Regular slub yarns: These yarns have evenly spaced slubs of consistent size.

- Random slub yarns: These yarns have slubs that are randomly spaced and vary in size.

- Fancy slub yarns: These yarns have slubs that are intentionally designed to create unique patterns or effects.

6. Discuss the applications of slub yarns in various textile products.

- Denim: Slub yarns are widely used in the production of slubbed denim, which has a unique texture and appearance.

- Knitwear: Slub yarns are used to create slubbed knits, which have a soft, textured feel.

- Tweeds: Slub yarns can be used to add texture and interest to tweed fabrics.

- Home textiles: Slub yarns are used in the production of throws, blankets, and other home textiles.

7. Explain the quality parameters that are important for slub yarns.

- Slub size and spacing: The size and spacing of the slubs should be consistent and meet the desired specifications.

- Yarn strength: The yarn should have adequate strength to withstand the rigors of knitting, weaving, or crocheting.

- Yarn evenness: The yarn should have a consistent diameter throughout its length.

- Dye receptivity: The yarn should dye evenly to achieve the desired color.

8. Describe the challenges involved in working with slub yarns.

- Uneven texture: The uneven texture of slub yarns can make them more difficult to work with during knitting, weaving, or crocheting.

- Weaker yarn: The presence of slubs can weaken the yarn, making it more susceptible to breakage.

- Pilling: Slub yarns are more prone to pilling due to their uneven texture.

9. Discuss the future trends in the use of slub yarns.

Slub yarns are becoming increasingly popular in the textile industry due to their unique texture and appearance. Some future trends in the use of slub yarns include:

- Increased use in sustainable textiles: Slub yarns can be made from recycled fibers, making them a more sustainable option.

- Development of new slubbing techniques: New slubbing techniques are being developed to create unique and innovative slub effects.

- Expanded use in high-end textiles: Slub yarns are becoming more popular in high-end textiles, such as luxury clothing and home décor.

10. What are some of the innovative applications of slub yarns?

- Slubbed 3D printing: Slub yarns can be used in 3D printing to create objects with unique textures and patterns.

- Slubbed composites: Slub yarns can be used to create composites with improved strength and durability.

- Slubbed sensors: Slub yarns can be used to create sensors that can detect changes in temperature, pressure, and other environmental factors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slubber Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slubber Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slubber Hands are responsible for operating slubbing machines in textile mills to create a unique yarn with slubs or irregular thick and thin sections. Their primary duties encompass:

1. Machine Operation and Maintenance

Operate slubbing machines to produce slub yarn according to specified parameters, ensuring consistent quality and production efficiency.

- Monitor machine performance, identify and resolve malfunctions promptly to minimize downtime.

- Perform routine maintenance tasks such as cleaning, lubrication, and adjustments to keep machines running smoothly.

2. Yarn Quality Control

Inspect slub yarn for defects, variations in thickness, and other quality issues using gauges and visual observation.

- Take corrective actions to address defects, such as adjusting machine settings or replacing worn parts.

- Maintain detailed records of yarn production and quality parameters for traceability and quality improvement purposes.

3. Material Handling

Load and unload yarn from machines, ensuring proper handling and storage to prevent damage.

- Inspect raw materials, such as roving or sliver, for consistency and suitability for slubbing.

- Collaborate with other operators to ensure smooth flow of materials and efficient production.

4. Safety and Compliance

Adhere to all safety protocols and regulations related to machine operation and handling of textile materials.

- Maintain a clean and organized work area, reducing the risk of accidents and promoting efficiency.

- Follow established guidelines for waste disposal and environmental protection.

Interview Tips

Preparing thoroughly for a Slubber Hand interview is crucial to showcase your skills and increase your chances of success. Here are some effective interview preparation tips:

1. Research the Company and Role

Familiarize yourself with the textile industry, the specific company you’re applying to, and the responsibilities of the Slubber Hand position. Research their website, news articles, and social media to gain insights into their operations and culture.

2. Practice Common Interview Questions

Anticipate common interview questions related to your technical skills, experience, and personal attributes. Prepare thoughtful responses that highlight your qualifications and enthusiasm for the role. Consider practicing with a friend or mentor to gain feedback.

3. Showcase Your Technical Expertise

Emphasize your proficiency in operating slubbing machines, understanding yarn quality parameters, and performing maintenance tasks. Provide specific examples of how you have resolved technical issues or improved production efficiency in previous roles.

4. Highlight Your Attention to Detail

Stress your ability to inspect yarn for defects and ensure consistent quality. Share examples of how you have implemented quality control measures or identified and corrected production errors.

5. Convey Your Safety-Consciousness

Demonstrate your commitment to workplace safety by highlighting your adherence to safety protocols and your understanding of the potential hazards associated with textile machinery. Emphasize your attention to maintaining a clean and organized work environment.

6. Prepare Industry-Specific Questions

Research the latest advancements in slubbing technology, yarn manufacturing trends, and industry best practices. Asking informed questions during the interview shows your interest in the field and your desire to stay updated.

7. Dress Professionally and Be Punctual

First impressions matter. Dress in business attire and arrive at the interview on time to convey professionalism and respect for the interviewer’s time.

8. Follow Up

After the interview, send a thank-you note expressing your appreciation for the opportunity. Reiterate your interest in the position and highlight any specific aspects of the interview that you found particularly engaging.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slubber Hand interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!