Are you gearing up for a career in Slubber Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Slubber Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

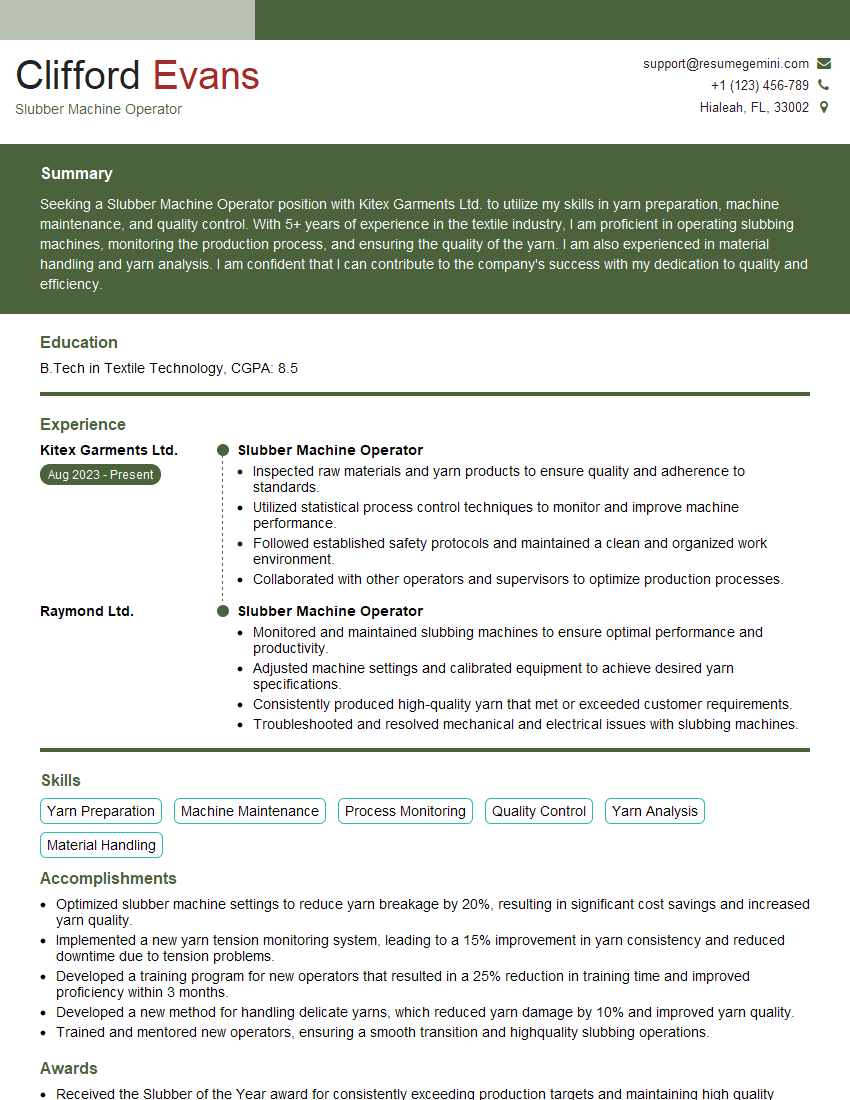

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slubber Machine Operator

1. How do you adjust the twist level in a slubber machine?

The twist level in a slubber machine can be adjusted by:

- Changing the gear ratio of the twisting mechanism

- Varying the speed of the drafting rollers

- Adjusting the tension of the yarn

2. How do you determine the quality of the slub yarn?

Appearance

- Uniformity of slubs

- Absence of neps or other defects

Strength

- Tensile strength

- Elongation at break

Handle

- Softness

- Bulkiness

3. How do you troubleshoot a slubbing machine that is producing uneven yarn?

Uneven yarn can be caused by a number of factors, including:

- Improper adjustment of the drafting system

- Worn or damaged rollers

- Variations in the raw material

To troubleshoot the problem, you should:

- Check the settings of the drafting system

- Inspect the rollers for wear or damage

- Examine the raw material for variations in quality

4. How do you change the creel on a slubbing machine?

To change the creel on a slubbing machine, you should:

- Unload the empty creel

- Load the full creel onto the machine

- Thread the yarn through the machine

- Start the machine and adjust the settings

5. How do you maintain a slubbing machine?

To maintain a slubbing machine, you should:

- Regularly clean and lubricate the machine

- Inspect the machine for wear or damage

- Calibrate the machine regularly

- Train operators on the proper use and maintenance of the machine

6. What are the safety precautions that should be taken when operating a slubbing machine?

When operating a slubbing machine, you should:

- Wear appropriate safety gear, including eye protection, gloves, and earplugs

- Keep the work area clean and free of debris

- Be aware of the moving parts of the machine

- Do not operate the machine if you are tired or under the influence of drugs or alcohol

7. What are the different types of slub yarns?

There are many different types of slub yarns, including:

- Regular slub yarn

- Random slub yarn

- Intentional slub yarn

- Overfeed slub yarn

- Underfeed slub yarn

8. What are the applications of slub yarns?

Slub yarns are used in a variety of applications, including:

- Apparel

- Home furnishings

- Industrial products

9. What is the history of slub yarns?

Slub yarns have been used for centuries. The first slub yarns were produced in India in the 16th century. Slub yarns became popular in Europe in the 18th century, and they have been used in a variety of applications ever since.

10. What are the future trends in slub yarns?

The future of slub yarns is bright. Slub yarns are becoming increasingly popular in a variety of applications, and they are expected to continue to grow in popularity in the years to come.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slubber Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slubber Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slubber Machine Operators play a crucial role in textile production, ensuring the efficient operation of slubbing machines to produce high-quality yarn. Their key job responsibilities include:

1. Machine Operation and Maintenance

Operate and monitor slubbing machines, ensuring proper functioning and adherence to production standards.

- Monitor machine settings, yarn quality, and machine performance.

- Perform routine maintenance tasks, such as cleaning, adjusting, and lubricating machines.

2. Yarn Handling and Quality Control

Handle yarn with care throughout the slubbing process, ensuring minimal breakage and contamination.

- Inspect yarn for defects, ensuring compliance with quality specifications.

- Adjust machine settings and parameters to optimize yarn quality.

3. Production Monitoring and Reporting

Monitor production output, record data, and report any deviations from established standards.

- Keep accurate records of production quantities, machine performance, and downtime.

- Identify and report any production issues or quality concerns to supervisors.

4. Safety and Housekeeping

Maintain a safe and clean work environment, adhering to established safety protocols.

- Wear appropriate safety gear, including gloves, earplugs, and safety glasses.

- Keep the work area clean and organized, minimizing hazards and ensuring efficient operations.

Interview Tips

To ace the interview for a Slubber Machine Operator position, candidates should prepare thoroughly and showcase their skills and experience. Here are some tips to help you prepare:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This knowledge will demonstrate your interest in the organization and the industry you’ll be working in.

- Visit the company’s website, LinkedIn page, and industry publications.

- Understand the company’s mission, values, and key products.

2. Highlight Your Skills and Experience

Tailor your resume and interview answers to focus on your relevant skills and experience. Emphasize your ability to operate slubbing machines efficiently, handle yarn with precision, and maintain a high level of quality.

- Quantify your accomplishments using specific metrics, such as production output or yarn quality improvement.

- Provide examples of your problem-solving skills and ability to identify and resolve machine issues.

3. Demonstrate Your Safety and Quality Consciousness

Employers value candidates who prioritize safety and quality. Highlight your commitment to adhering to safety protocols and your ability to identify and correct quality defects.

- Describe your experience with safety procedures and regulations in previous roles.

- Explain how you ensure yarn quality by conducting regular inspections and monitoring machine performance.

4. Prepare for Common Interview Questions

Research common interview questions and prepare thoughtful answers that showcase your skills and enthusiasm for the role. Practice your answers to ensure they are clear, concise, and highlight your strengths.

- Example Outline:

- Tell me about your experience operating slubbing machines.

- How do you ensure consistent yarn quality on the production line?

5. Ask Informed Questions

At the end of the interview, ask informed questions about the company, the role, and the industry. This shows your genuine interest in the position and your desire to learn more.

- Inquire about the company’s production goals and quality standards.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Slubber Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Slubber Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.