Are you gearing up for an interview for a Slubber Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Slubber Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

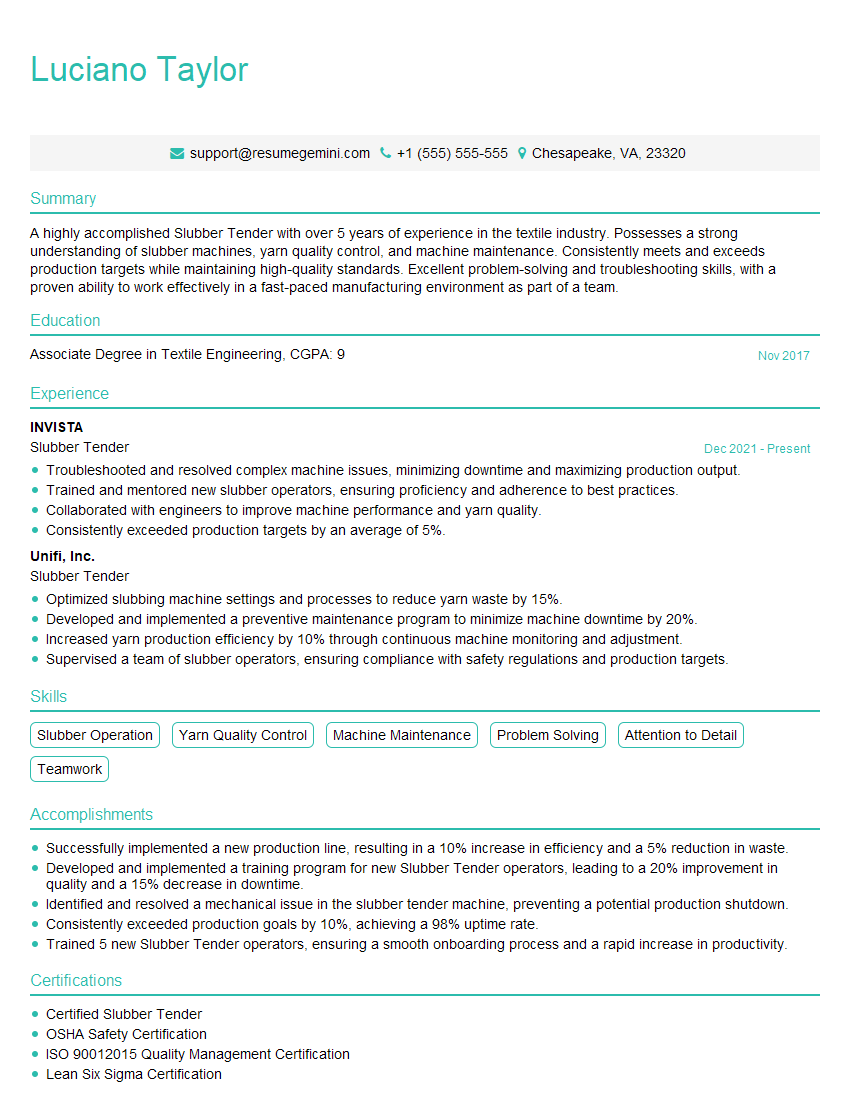

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slubber Tender

1. What are the key responsibilities of a Slubber Tender?

- Operate and monitor slubbing machines to produce yarn with the desired effect.

- Inspect yarn for defects, adjust machine settings, and perform maintenance as needed.

- Maintain a clean and safe work area, and adhere to safety regulations.

- Work effectively as part of a team and communicate effectively with supervisors and colleagues.

2. Describe the different types of slubbing machines?

Principle of Operation

- Creel Feed – Continuous feed with variable tension.

- Pressure Roll Feed – Positive feed with precise control

- Cots and Apron Draft – Fiber control with drafting action

- Slubbing Roller- Twisting, drafting, and laying down the fibers

Types

- Conventional Slubber

- High Speed Slubber

- Automatic Slubber

- Electronic Slubber

3. What are the factors that affect the quality of slub yarn?

- Fiber properties – length, fineness, strength

- Machine settings – speed, draft, twist

- Environmental conditions – temperature, humidity

- Operator skills – experience, attention to detail

4. How do you troubleshoot common problems that occur during slubbing?

- Yarn breakage – adjust machine settings, check for fiber defects

- Uneven slubs – adjust draft or twist settings, check for worn parts

- Poor yarn quality – check fiber quality, machine settings, and environmental conditions

5. What are the safety precautions that must be followed when operating a slubbing machine?

- Wear appropriate safety gear, including gloves and eye protection

- Keep hands and clothing away from moving parts

- Be aware of potential hazards, such as entanglement in yarn

- Report any unsafe conditions or equipment malfunctions immediately

6. How do you maintain a slubbing machine to ensure optimal performance?

- Regularly clean and lubricate all moving parts

- Inspect belts, pulleys, and gears for wear and tear

- Check and adjust machine settings as needed

- Keep the work area clean and free of debris

7. What are the different types of yarn that can be produced using a slubbing machine?

- Slub yarn – yarn with intentionally created thick and thin sections

- Bouclé yarn – yarn with loops or curls

- Chenille yarn – yarn with a soft, velvety texture

8. How do you calculate the draft and twist of a slubbing machine?

- Draft – the ratio of the input yarn diameter to the output yarn diameter

- Twist – the number of turns per inch or meter

- Use formulas provided by the machine manufacturer or industry standards

9. What are the different types of slubbing attachments available?

- Mechanical attachments – gears, cams, eccentrics

- Electronic attachments – sensors, actuators, microprocessors

- Pneumatic attachments – air cylinders, valves

10. How do you ensure that the slub yarn meets the required specifications?

- Regularly monitor yarn quality using testing equipment

- Adjust machine settings and parameters as needed

- Maintain a consistent work environment

- Use high-quality raw materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slubber Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slubber Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slubber Tenders are responsible for operating and maintaining slubbing machines, which are used to create slubs (small, intentionally uneven areas) in yarn. Their key responsibilities include:

1. Machine Operation

Starting, stopping, and adjusting slubbing machines to produce yarn with the desired specifications.

- Monitoring machine operation to ensure smooth running and identify any potential issues.

- Making necessary adjustments to machine settings to optimize yarn quality and production efficiency.

2. Yarn Quality Control

Inspecting yarn produced by the slubbing machine to ensure it meets quality standards.

- Checking for defects such as unevenness, slubs, and breaks in the yarn.

- Adjusting machine settings or replacing components as needed to maintain yarn quality.

3. Maintenance and Troubleshooting

Performing routine maintenance tasks on slubbing machines to ensure optimal performance.

- Cleaning and lubricating machine components to prevent wear and tear.

- Troubleshooting and resolving machine malfunctions to minimize downtime.

4. Production Monitoring

Monitoring yarn production rates and ensuring that machines are meeting production targets.

- Keeping records of yarn production data for quality control and inventory purposes.

- Reporting any production issues or machine downtime to supervisors.

Interview Tips

Preparing thoroughly for a Slubber Tender interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific Slubber Tender role you are applying for. This will demonstrate your interest in the position and help you tailor your answers to the company’s needs.

- Visit the company’s website to learn about their history, values, and products or services.

- Read the job description carefully to understand the key responsibilities and qualifications required for the role.

2. Highlight Relevant Experience and Skills

During the interview, focus on highlighting your relevant experience and skills that align with the job requirements. Use specific examples to demonstrate your abilities in machine operation, yarn quality control, maintenance, and troubleshooting.

3. Emphasize Safety and Attention to Detail

Slubber Tenders play a crucial role in ensuring the safety and efficiency of the production process. Emphasize your commitment to safety and your attention to detail in your answers.

- Share examples of how you have maintained a safe work environment and followed safety protocols.

- Highlight your ability to identify and resolve potential issues before they become major problems.

4. Prepare for Common Interview Questions

In addition to questions about your experience and qualifications, there are several common interview questions that you should prepare for:

- “Why are you interested in this role?”

- “Tell me about your experience operating and maintaining slubbing machines.”

- “How do you ensure the quality of the yarn produced by the slubbing machine?”

- “What are your strengths and weaknesses as a Slubber Tender?”

- “Why should we hire you for this role?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slubber Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!