Are you gearing up for a career in Slurry Blender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Slurry Blender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

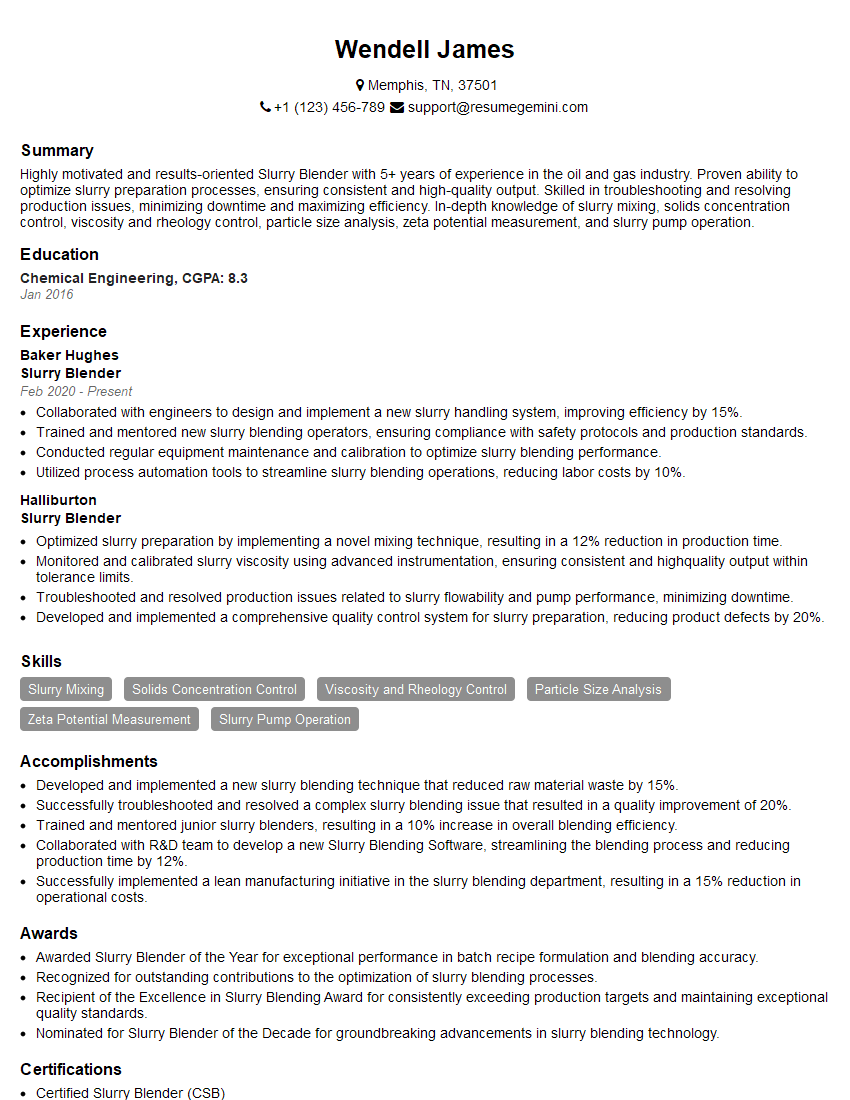

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slurry Blender

1. What are the key principles of slurry blending?

- Understanding the rheology of the slurry

- Selecting the appropriate blending equipment

- Controlling the process parameters to achieve the desired results

2. What are the different types of slurry blenders?

Types of Slurry Blenders

- Batch blenders

- Continuous blenders

Batch Blenders

- Less expensive

- Slower blending time

Continuous Blenders

- Higher cost

- Faster blending time

3. What are the factors to consider when selecting a slurry blender?

- The type of slurry

- The desired blend uniformity

- The throughput rate

- The budget

4. What are the common problems encountered in slurry blending?

- Caking

- Segregation

- Agglomeration

5. How can these problems be prevented or solved?

- Using anti-caking agents

- Increasing the agitation rate

- Adding a wetting agent

6. What are the safety precautions that must be taken when operating a slurry blender?

- Wear proper personal protective equipment (PPE)

- Follow the manufacturer’s operating instructions

- Be aware of the potential hazards associated with the slurry

7. What is your experience with slurry blending?

- Describe your previous experience with slurry blending

- Highlight your skills and knowledge in this area

- Explain how your experience can benefit the company

8. What are your expectations for this role?

- Describe your expectations for the role

- Explain how you can contribute to the team’s success

- Express your interest in learning and growing within the company

9. What are your strengths and weaknesses?

- Highlight your strengths that are relevant to the role

- Acknowledge your weaknesses and explain how you are working to improve them

- Be honest and self-aware

10. Do you have any questions for me?

- Ask questions about the role

- Ask questions about the company

- Ask questions about the team

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slurry Blender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slurry Blender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slurry Blenders are responsible for operating and maintaining slurry blending equipment, ensuring that the correct proportions of materials are mixed to produce a consistent and homogeneous slurry. Their key job responsibilities include:

1. Operate Slurry Blending Equipment

Operate and control slurry blending equipment, including mixers, pumps, and conveyors, to ensure the proper mixing and blending of materials.

- Monitor and adjust equipment settings to achieve desired slurry consistency, viscosity, and other specifications.

- Ensure that equipment is properly calibrated and maintained to prevent contamination and ensure accurate blending.

2. Prepare and Weigh Materials

Prepare and weigh raw materials according to specified proportions and recipes, using scales and measuring devices.

- Check the quality and condition of raw materials before blending to ensure they meet specifications.

- Calculate and adjust material quantities based on changes in product formulations or batch sizes.

3. Monitor and Control Blending Process

Monitor the blending process, including temperature, pH, and mixing time, to ensure that the desired product quality is achieved.

- Take samples of the slurry during the blending process to check consistency and homogeneity.

- Adjust blending parameters and troubleshoot any issues that may arise during the process.

4. Clean and Maintain Equipment

Clean and maintain slurry blending equipment, including tanks, mixers, and pipelines, to prevent contamination and ensure proper functioning.

- Follow established cleaning and sanitization procedures to maintain a clean and hygienic work environment.

- Inspect equipment for wear and tear, and report any maintenance or repair needs.

Interview Tips

Preparing for a Slurry Blender interview requires a combination of technical knowledge, attention to detail, and a strong understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Before the interview, take the time to research the company and the slurry blending industry. This will help you understand the company’s products, services, and market position.

- Visit the company’s website to learn about their operations, mission, and recent news.

- Read industry publications and articles to stay up-to-date on trends and best practices in slurry blending.

2. Highlight Your Technical Skills

In the interview, emphasize your technical skills and experience in slurry blending. This includes knowledge of blending equipment, materials handling, and quality control procedures.

- Showcase your ability to operate and troubleshoot slurry blending equipment, such as mixers, pumps, and conveyors.

- Discuss your experience in preparing and weighing raw materials, and maintaining accurate records of material usage.

3. Demonstrate Your Attention to Detail

Slurry blending requires precise attention to detail to ensure consistent product quality. Highlight your ability to follow instructions carefully, adhere to safety protocols, and maintain a clean and organized work environment.

- Describe your experience in monitoring and controlling the blending process, including temperature, pH, and mixing time.

- Emphasize your commitment to quality control and your ability to identify and resolve any issues that may arise during the blending process.

4. Be Enthusiastic and Professional

A positive and professional attitude can make a great impression on interviewers. Show your enthusiasm for the role and your willingness to contribute to the company’s success.

- Express your interest in the company and the industry, and explain why you are passionate about slurry blending.

- Dress professionally and arrive on time for your interview to demonstrate your commitment to the opportunity.

Next Step:

Now that you’re armed with the knowledge of Slurry Blender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Slurry Blender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini