Are you gearing up for a career in Slurry Tank Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Slurry Tank Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

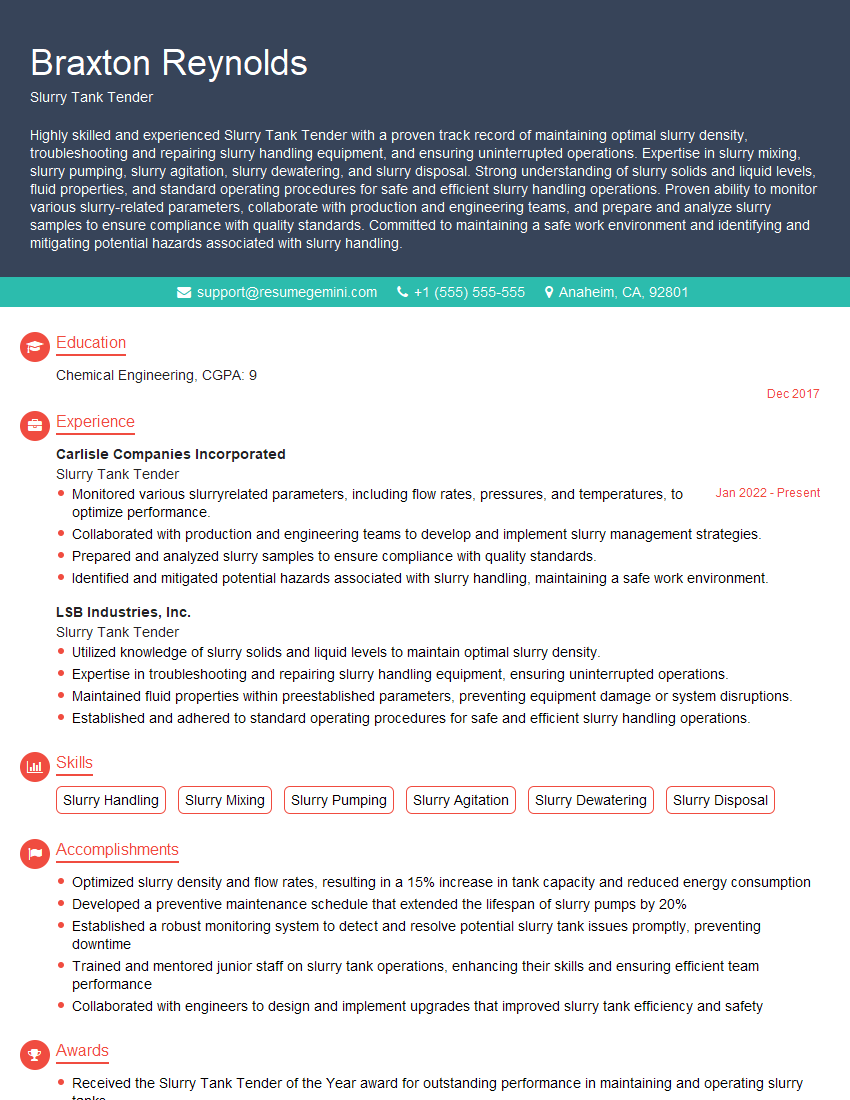

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slurry Tank Tender

1. Explain the process of preparing a slurry tank for use.

The process of preparing a slurry tank for use involves the following steps:

- Inspect the tank for any damage or leaks.

- Clean the tank thoroughly using a high-pressure washer.

- Calibrate the tank’s agitator and pump to ensure they are working properly.

- Fill the tank with water to the desired level.

- Add the appropriate amount of slurry to the tank.

- Start the agitator and pump to mix the slurry thoroughly.

2. What are the different types of slurry tanks and what are their advantages and disadvantages?

Types of Slurry Tanks:

- Vacuum tanks use a vacuum pump to create a negative pressure inside the tank, which draws slurry into the tank.

- Pump tanks use a pump to move slurry into and out of the tank.

- Gravity tanks rely on gravity to move slurry into and out of the tank.

Advantages and Disadvantages:

- Vacuum tanks are the most efficient type of slurry tank, but they are also the most expensive.

- Pump tanks are less efficient than vacuum tanks, but they are also less expensive.

- Gravity tanks are the least efficient type of slurry tank, but they are also the least expensive.

3. How do you operate a slurry tank safely?

To operate a slurry tank safely, it is important to follow the following guidelines:

- Wear appropriate personal protective equipment (PPE), including gloves, boots, and coveralls.

- Never enter a slurry tank without first being trained and authorized.

- Keep the tank filled with water to prevent the slurry from drying out and becoming hazardous.

- Do not operate the tank in windy conditions.

- Be aware of your surroundings and be careful not to hit anything with the tank.

4. What are the environmental regulations that apply to the use of slurry tanks?

The environmental regulations that apply to the use of slurry tanks vary depending on the location. However, some general regulations include:

- Slurry must be applied to land in a manner that prevents runoff into surface waters.

- Slurry must be applied to land at a rate that does not exceed the crop’s nutrient requirements.

- Slurry must be stored in a manner that prevents leaks and spills.

5. What are the common problems that can occur with slurry tanks and how do you troubleshoot them?

Some common problems that can occur with slurry tanks include:

- Clogged nozzles can be cleared by using a high-pressure washer.

- Leaking valves can be repaired by replacing the O-rings or gaskets.

- Pump problems can be diagnosed by checking the pump’s pressure and flow rate.

- Agitator problems can be diagnosed by checking the agitator’s speed and torque.

6. What are the different types of slurry spreading equipment and what are their advantages and disadvantages?

Types of Slurry Spreading Equipment:

- Trailing shoe applicators are towed behind a tractor and spread slurry in a wide band.

- Injection applicators inject slurry directly into the soil.

- Band spreaders spread slurry in a narrow band.

Advantages and Disadvantages:

- Trailing shoe applicators are the most common type of slurry spreading equipment because they are relatively inexpensive and easy to operate.

- Injection applicators are more expensive than trailing shoe applicators, but they are more efficient and environmentally friendly.

- Band spreaders are the most expensive type of slurry spreading equipment, but they are the most accurate and efficient.

7. How do you calibrate a slurry spreading equipment?

To calibrate a slurry spreading equipment, follow these steps:

- Fill the tank with water to the desired level.

- Set the spreading width and rate.

- Drive the equipment over a known distance.

- Collect the slurry that is spread and measure the volume.

- Adjust the spreading width and rate until the desired application rate is achieved.

8. What are the different types of slurry tankers and what are their capacities?

Types of Slurry Tankers:

- Single-axle tankers are the most common type of slurry tanker.

- Tandem-axle tankers have two axles, which increases their capacity and stability.

- Tridem-axle tankers have three axles, which further increases their capacity and stability.

Capacities:

- Single-axle tankers typically have a capacity of 2,500 to 4,000 gallons.

- Tandem-axle tankers typically have a capacity of 4,000 to 6,000 gallons.

- Tridem-axle tankers typically have a capacity of 6,000 to 8,000 gallons.

9. What are the safety precautions that must be taken when working with slurry?

When working with slurry, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, boots, and coveralls.

- Never enter a slurry tank without first being trained and authorized.

- Be aware of the potential hazards of slurry, including its corrosive and flammable properties.

- Follow all safety procedures and guidelines.

10. What are the environmental regulations that apply to the storage and disposal of slurry?

The environmental regulations that apply to the storage and disposal of slurry vary depending on the location. However, some general regulations include:

- Slurry must be stored in a manner that prevents leaks and spills.

- Slurry must be disposed of in a manner that does not pollute surface waters or groundwater.

- Slurry must be applied to land in a manner that prevents runoff into surface waters.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slurry Tank Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slurry Tank Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slurry Tank Tenders play a crucial role in maintaining a clean and safe environment within the farming industry. Their primary responsibilities entail managing slurry tanks and ensuring the proper collection, storage, and disposal of animal waste.

1. Slurry Tank Management

Tenders operate and maintain slurry tanks, ensuring they are in good working order and compliant with safety regulations.

- Monitor tank levels, ensuring timely emptying to prevent overflow and environmental contamination.

- Operate and maintain pumps and agitators to keep slurry mixed and prevent sedimentation.

2. Slurry Collection and Disposal

Tenders are responsible for the efficient collection and disposal of slurry, adhering to environmental regulations and minimizing odor.

- Use vacuum tankers or other equipment to collect slurry from farm buildings and holding areas.

- Transport slurry to designated storage facilities or disposal sites in compliance with legal requirements.

3. Record Keeping and Compliance

Tenders maintain accurate records and adhere to legal regulations related to slurry management.

- Keep detailed records of slurry volumes, collection schedules, and disposal methods.

- Ensure compliance with environmental regulations and industry best practices.

4. Health and Safety

Tenders prioritize health and safety in their work environment.

- Wear appropriate protective gear, including masks and gloves, when handling slurry.

- Follow safety protocols for operating machinery and handling hazardous materials.

Interview Preparation Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some practical tips to help you ace the interview for a Slurry Tank Tender position.

1. Research the Company and Industry

Familiarize yourself with the company’s values, operations, and the industry’s current best practices.

- Visit the company’s website and social media pages.

- Read industry news and articles to demonstrate your knowledge and interest.

Example Outline:

- Explain how your understanding of the company’s environmental commitment aligns with your values.

- Discuss a recent industry trend or innovation and how it impacts slurry management.

2. Highlight Relevant Experience and Skills

Emphasize your experience and skills that are directly relevant to the job responsibilities. Quantify your achievements whenever possible.

- Describe your experience operating and maintaining slurry tanks.

- Explain your knowledge of slurry collection and disposal regulations.

Example Outline:

- Quantify the number of slurry tanks you have managed and the average volume of slurry handled.

- Provide examples of how you have improved compliance with environmental regulations.

3. Demonstrate Health and Safety Awareness

Show the interviewer that you prioritize health and safety in the workplace.

- Explain your understanding of the potential hazards associated with handling slurry.

- Describe your experience following safety protocols and wearing appropriate protective gear.

Example Outline:

- Mention your knowledge of the latest safety regulations and your commitment to following them.

- Share an example of a time when you identified and mitigated a potential safety hazard.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions shows interest and engagement. Ask questions that demonstrate your knowledge and enthusiasm for the role.

- Inquire about the company’s environmental sustainability goals.

- Ask about opportunities for professional development and advancement.

Example Outline:

- Explain how your values align with the company’s commitment to environmental stewardship.

- Discuss your aspirations for career growth and how the company can support your goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slurry Tank Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!