Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Small Engine Specialist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

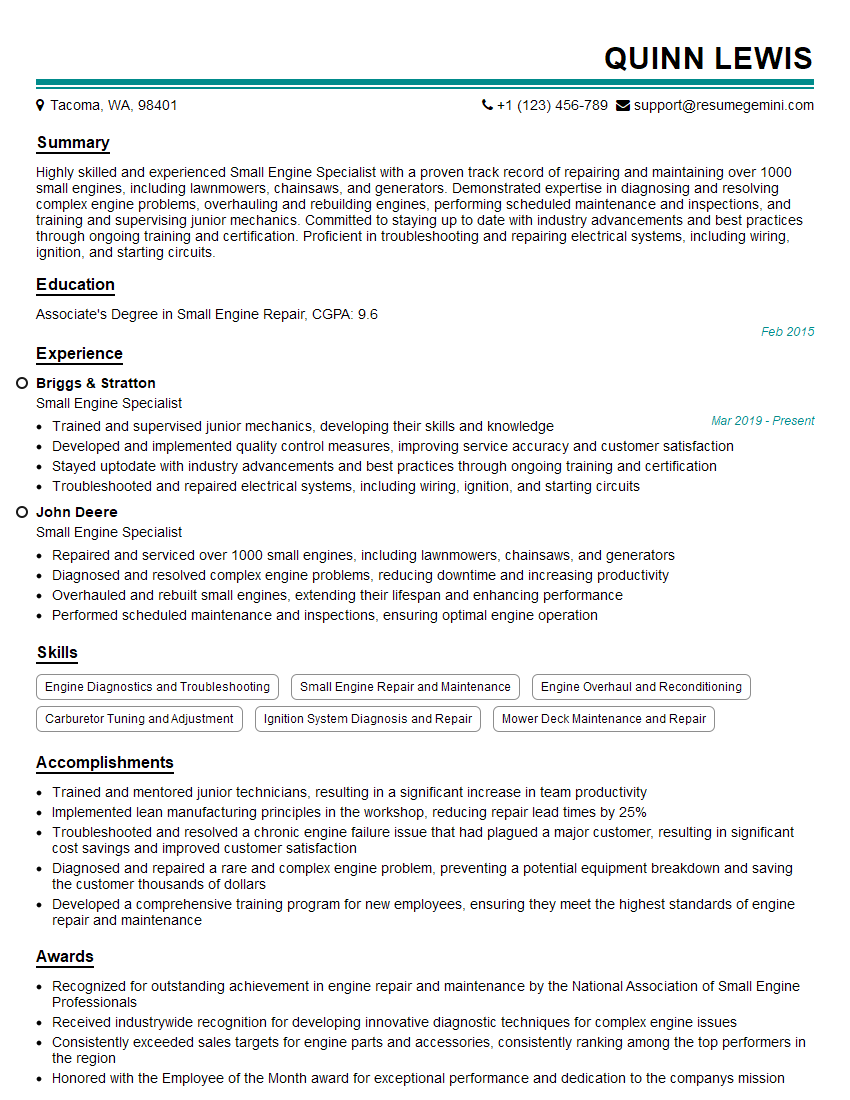

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Small Engine Specialist

1. Explain the basic components of a small engine and their functions?

The basic components of a small engine include:

- Engine block: The engine block is the main structural component of the engine and houses the cylinders, crankshaft, and other internal components.

- Cylinder head: The cylinder head is located at the top of the engine block and houses the valves, camshaft, and spark plug.

- Piston: The piston is a cylindrical-shaped component that moves up and down inside the cylinder, creating compression and power.

- Crankshaft: The crankshaft is a rotating shaft that converts the reciprocating motion of the piston into rotary motion.

- Connecting rod: The connecting rod connects the piston to the crankshaft, allowing the piston to move up and down.

- Valves: The valves control the flow of air and fuel into and out of the cylinder.

- Camshaft: The camshaft is a shaft that controls the timing of the valves.

- Spark plug: The spark plug provides the electrical spark that ignites the air-fuel mixture in the cylinder.

2. Describe the different types of small engines and their applications?

2-Stroke Engines

- Simpler design: Fewer moving parts compared to 4-stroke engines, making them easier to maintain.

- Higher power-to-weight ratio: Produce more power for their size, making them suitable for applications where weight and space are limited.

- Applications: Used in small handheld power equipment such as chainsaws, trimmers, and leaf blowers.

4-Stroke Engines

- More efficient: Convert more of the fuel’s energy into power, resulting in lower fuel consumption.

- Cleaner emissions: Produce fewer emissions compared to 2-stroke engines, making them more environmentally friendly.

- Applications: Used in larger equipment such as lawnmowers, generators, and small industrial machinery.

3. Explain the fuel system of a small engine and its components?

The fuel system of a small engine includes:

- Fuel tank: Stores the fuel.

- Fuel line: Delivers fuel from the fuel tank to the carburetor.

- Carburetor: Mixes air and fuel in the correct ratio for combustion.

- Throttle: Controls the amount of fuel-air mixture entering the engine.

- Fuel filter: Removes impurities from the fuel before it enters the carburetor.

- Fuel pump: In some engines, a fuel pump is used to deliver fuel to the carburetor.

4. What are the common problems associated with small engines and their troubleshooting steps?

Common problems associated with small engines include:

- Engine won’t start: Check for fuel, spark, and compression.

- Engine runs rough: Check for carburetor problems, spark plug issues, or fuel filter clogs.

- Engine overheating: Check for coolant leaks, clogged air filters, or dirty cooling fins.

- Excessive smoke: Check for worn piston rings, leaking valve seals, or improper fuel mixture.

- Loss of power: Check for carburetor problems, worn piston rings, or ignition issues.

5. How do you perform a compression test on a small engine?

To perform a compression test on a small engine:

- Remove the spark plug.

- Insert a compression tester into the spark plug hole.

- Crank the engine over several times.

- Read the compression pressure on the tester gauge.

- Compare the reading to the manufacturer’s specifications.

6. What are the safety precautions you observe when working on small engines?

- Disconnect the spark plug: This prevents accidental starting during maintenance or repairs.

- Wear appropriate PPE: Use gloves, safety glasses, and ear protection to minimize the risk of injury.

- Allow the engine to cool: Hot engine components can cause burns.

- Use the correct tools: Use tools specifically designed for small engine repair to avoid damage.

- Follow proper lifting techniques: Heavy components should be lifted safely to prevent strain or injury.

7. What techniques do you use to diagnose and repair electrical problems in small engines?

- Visual inspection: Check for loose wires, damaged connectors, or burnt components.

- Voltage testing: Use a voltmeter to measure voltage at various points in the electrical system.

- Continuity testing: Use a multimeter to check for continuity in electrical circuits.

- Component replacement: If a faulty component is identified, replace it with a new one.

- Wiring diagrams: Use wiring diagrams to trace electrical circuits and identify potential problems.

8. How do you ensure the proper maintenance and storage of small engines?

- Regular maintenance: Follow manufacturer’s maintenance schedules for tasks such as oil changes, filter replacements, and air filter cleaning.

- Proper storage: Store engines in a clean, dry place, with the fuel tank drained and the spark plug removed.

- Stabilize fuel: Add fuel stabilizer to the fuel tank before storage to prevent fuel degradation.

- Lubricate moving parts: Apply lubricant to moving parts such as bearings, linkages, and throttle controls.

- Protect from corrosion: Apply anti-corrosion spray to metal surfaces to prevent rust.

9. What are the latest advancements in small engine technology?

- Fuel injection: Fuel injection systems provide more precise fuel metering and improve engine efficiency.

- Electronic ignition: Electronic ignition systems offer more reliable starting and ignition timing.

- Computer controls: Computer modules optimize engine performance by controlling fuel, ignition, and emissions.

- Hybrid engines: Hybrid engines combine gasoline and electric power to improve fuel economy and reduce emissions.

- Materials improvements: Advanced materials such as lightweight alloys and ceramic composites improve engine durability and performance.

10. How do you stay updated on the latest developments in the small engine industry?

- Attend industry conferences and trade shows: These events provide opportunities to learn about new products and technologies.

- Read trade magazines and online forums: Industry publications and online communities share the latest news and technical information.

- Enroll in training programs: Manufacturers and industry organizations offer training programs to enhance technical skills and knowledge.

- Network with other professionals: Connect with other small engine specialists to share experiences and learn about new developments.

- Stay informed about industry regulations and standards: Keeping up with industry regulations and standards ensures compliance and safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Small Engine Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Small Engine Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Small Engine Specialist is responsible for repairing and maintaining various gasoline-powered equipment.

1. Troubleshooting and Diagnosing

identifying the root cause of small engine issues using diagnostic tools and techniques.

- Conducting compression tests to assess engine condition

- Analyzing exhaust emissions to identify potential problems

2. Repairs and Maintenance

Performing necessary repairs to restore engine functionality, including:

- Replacing spark plugs, filters, and other components

- Adjusting carburetors and governors

3. Engine Overhaul

Completely disassembling and rebuilding engines to address major issues, such as:

- Replacing pistons, rings, and valves

- Resurfacing cylinder heads and blocks

4. Customer Service

Interacting with customers to understand their needs and provide technical support.

- Explaining repair procedures and estimated costs

- Offering maintenance recommendations

Interview Tips

Preparing for a Small Engine Specialist interview requires a combination of technical knowledge and soft skills.

1. Research the Company and Industry

Demonstrating your understanding of the company’s products and services, as well as the latest industry trends, shows your enthusiasm for the field.

- Visit the company’s website and social media pages

- Read industry publications and attend webinars or conferences

2. Highlight Your Technical Skills

Provide specific examples of your experience diagnosing, repairing, and maintaining small engines.

- Quantify your accomplishments by mentioning the number of engines repaired or the percentage of customers satisfied

- Be prepared to discuss different types of engines and their common problems

3. Emphasize Customer Service Skills

Show that you enjoy interacting with customers and understand the importance of providing excellent service.

- Share examples of how you have effectively communicated with customers, resolved their concerns, and built lasting relationships

- Explain how you handle difficult customers or challenging situations

4. Prepare Questions to Ask

Asking thoughtful questions demonstrates your interest in the position and the company.

- Inquire about the company’s growth plans and opportunities for professional development

- Ask about the company’s commitment to customer satisfaction

Next Step:

Now that you’re armed with the knowledge of Small Engine Specialist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Small Engine Specialist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini