Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Small Engine Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

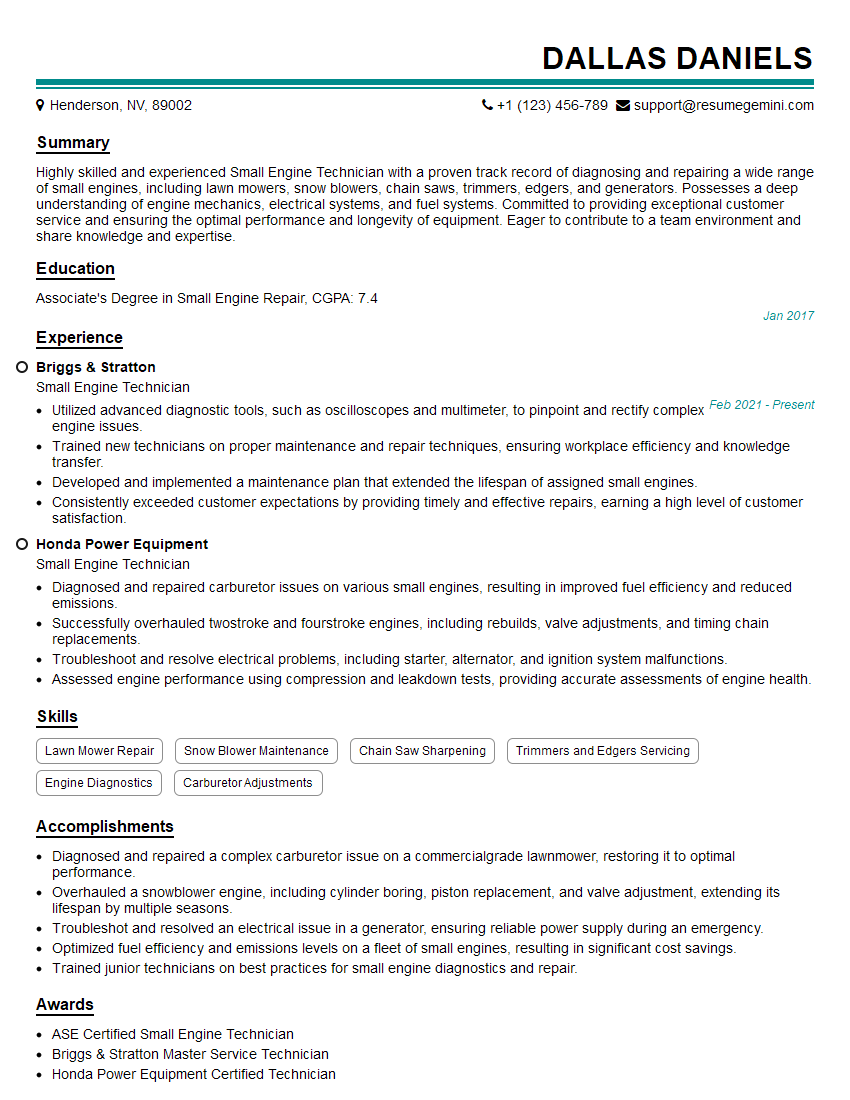

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Small Engine Technician

1. Can you describe the process of diagnosing a small engine problem?

To diagnose a small engine problem, I follow a systematic approach:

- Gather information: I start by gathering information about the engine’s history, symptoms, and operating conditions from the customer or observing the engine.

- Perform visual inspection: I conduct a thorough visual inspection of the engine, looking for any obvious signs of damage, loose connections, or leaks.

- Test engine components: I then use appropriate test equipment to check the function of individual components, such as spark plugs, compression, and fuel delivery.

- Analyze results: Based on the test results, I analyze the data to identify potential causes of the problem.

- Formulate a diagnosis: I use my knowledge and experience to formulate a diagnosis and determine the most likely cause of the issue.

2. How do you determine the correct fuel mixture for a two-stroke engine?

Determining the correct fuel mixture for a two-stroke engine depends on the specific engine and the manufacturer’s instructions.

Calculating Fuel Ratio

- I calculate the fuel-to-oil ratio using the manufacturer’s recommended ratio, which is typically expressed in parts of oil per parts of fuel (e.g., 50:1).

- For example, a 50:1 ratio means mixing 1 part of oil with 50 parts of fuel.

Using Premixed Fuel

- In some cases, premixed fuel may be available, eliminating the need for mixing.

- However, it’s crucial to ensure the premixed fuel is compatible with the specific engine.

3. Explain the function of a carburetor and how to adjust it for optimal performance.

A carburetor mixes air and fuel in the correct ratio for combustion in a small engine.

Function of a Carburetor

- It draws fuel from the fuel tank into the carburetor through a small tube called the fuel line.

- As air flows through the carburetor, it creates a vacuum that draws fuel into the air stream.

- The mixture of air and fuel is then sent to the engine’s cylinder.

Adjusting a Carburetor

- Idle speed screw: Adjusts the engine’s idle speed by controlling the amount of air bypassing the throttle plate.

- Fuel mixture screw: Adjusts the fuel-to-air ratio by regulating the amount of fuel entering the carburetor.

- Float adjustment: Ensures the correct fuel level in the carburetor’s float bowl.

4. Describe the different types of ignition systems used in small engines.

Small engines typically use three main types of ignition systems:

Magneto Ignition System

- Uses a permanent magnet to generate a high-voltage spark.

- Commonly found in older engines and small outdoor power equipment.

Battery Ignition System

- Relies on a battery to provide power for the ignition coil.

- Found in most modern small engines, providing reliable starting and performance.

Electronic Ignition System

- Uses electronic components, such as a transistor or integrated circuit, to control the ignition timing and spark.

- Provides precise spark timing and improved engine performance.

5. How do you troubleshoot an electrical problem in a small engine?

To troubleshoot an electrical problem in a small engine, I follow these steps:

- Check for loose connections: I inspect electrical connections, such as battery terminals, wire harnesses, and switches, for any loose or corroded connections.

- Test voltage and continuity: I use a multimeter to measure voltage at various points in the electrical system and check for continuity in wires and components.

- Inspect components: I examine individual electrical components, such as the starter solenoid, ignition coil, and alternator, for any signs of damage or malfunction.

- Follow wiring diagrams: I refer to wiring diagrams to trace electrical circuits and identify potential issues.

6. What are the common causes of overheating in small engines?

Overheating in small engines can be caused by several factors:

- Insufficient cooling: A lack of proper cooling, such as a faulty cooling fan or blocked air vents, can lead to overheating.

- Fuel mixture: Running the engine with an incorrect fuel-to-air ratio, usually too lean, can cause excessive heat buildup.

- Lubrication issues: Insufficient or dirty oil can result in increased friction and heat.

- Mechanical problems: Worn or seized components, such as pistons or bearings, can create friction and generate heat.

7. How do you perform a compression test on a small engine?

To perform a compression test on a small engine, I follow these steps:

- Remove the spark plug.

- Insert the compression tester into the spark plug hole.

- Pull the starter cord several times to build up compression.

- Record the highest reading on the compression gauge.

- Compare the reading to the manufacturer’s specifications.

8. What are the different types of valves used in small engines?

Small engines typically use two types of valves:

Intake Valves

- Allow the air-fuel mixture to enter the engine’s cylinder.

- Controlled by the camshaft and open at specific intervals.

Exhaust Valves

- Allow the exhaust gases to exit the engine’s cylinder.

- Also controlled by the camshaft and open after the combustion process.

9. How do you replace a piston ring on a small engine?

Replacing a piston ring on a small engine involves the following steps:

Removing the Piston

- Dismantle the engine and remove the cylinder head.

- Remove the piston pin and carefully pull the piston out of the cylinder.

Replacing the Ring

- Remove the old piston ring using a ring expander.

- Install the new piston ring onto the piston, ensuring it is seated properly in the ring groove.

- Reassemble the engine by inserting the piston into the cylinder, attaching the piston pin, and replacing the cylinder head.

10. What are the safety precautions to observe when working with small engines?

To maintain safety while working with small engines, it is crucial to adhere to the following precautions:

- Wear appropriate safety gear: Safety glasses, gloves, and earplugs.

- Disconnect the spark plug: To prevent accidental starting during repairs.

- Allow the engine to cool: Before handling hot components.

- Use proper tools: The right tools for the job to avoid damage and injury.

- Work in a well-ventilated area: To avoid inhaling harmful fumes.

- Keep away from rotating parts: To prevent entanglement and injury.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Small Engine Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Small Engine Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Small Engine Technicians are responsible for the efficient maintenance and repair of small engines, including those found in lawnmowers, generators, and other small motorized equipment.

1. Diagnostics and Troubleshooting

Identify and diagnose engine problems by performing inspections, using diagnostic tools, and conducting tests.

2. Engine Repair and Maintenance

Overhaul, repair, and replace engine components, including gaskets, pistons, valves, and spark plugs.

3. Fuel System Service

Inspect, clean, and repair fuel lines, filters, pumps, and carburetors.

4. Electrical System Maintenance

Troubleshoot electrical problems, repair wiring, and replace components such as batteries, alternators, and starters.

Interview Tips

To ace your Small Engine Technician interview, it’s crucial to prepare effectively. Here are some key tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the Small Engine Technician role. This will demonstrate your interest and enthusiasm.

2. Highlight Your Skills and Experience

Quantify your technical abilities and provide specific examples of your accomplishments. Use the STAR method (Situation, Task, Action, Result) to describe your work experience.

3. Showcase Your Diagnostic Expertise

Emphasize your ability to identify and troubleshoot engine problems. Provide examples of challenging diagnostics you have successfully handled.

4. Demonstrate Your Mechanical Aptitude

Highlight your proficiency in using hand tools, power tools, and diagnostic equipment. Describe your experience with small engine repair and maintenance.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Small Engine Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.