Are you gearing up for a career in Smelter Liner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Smelter Liner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

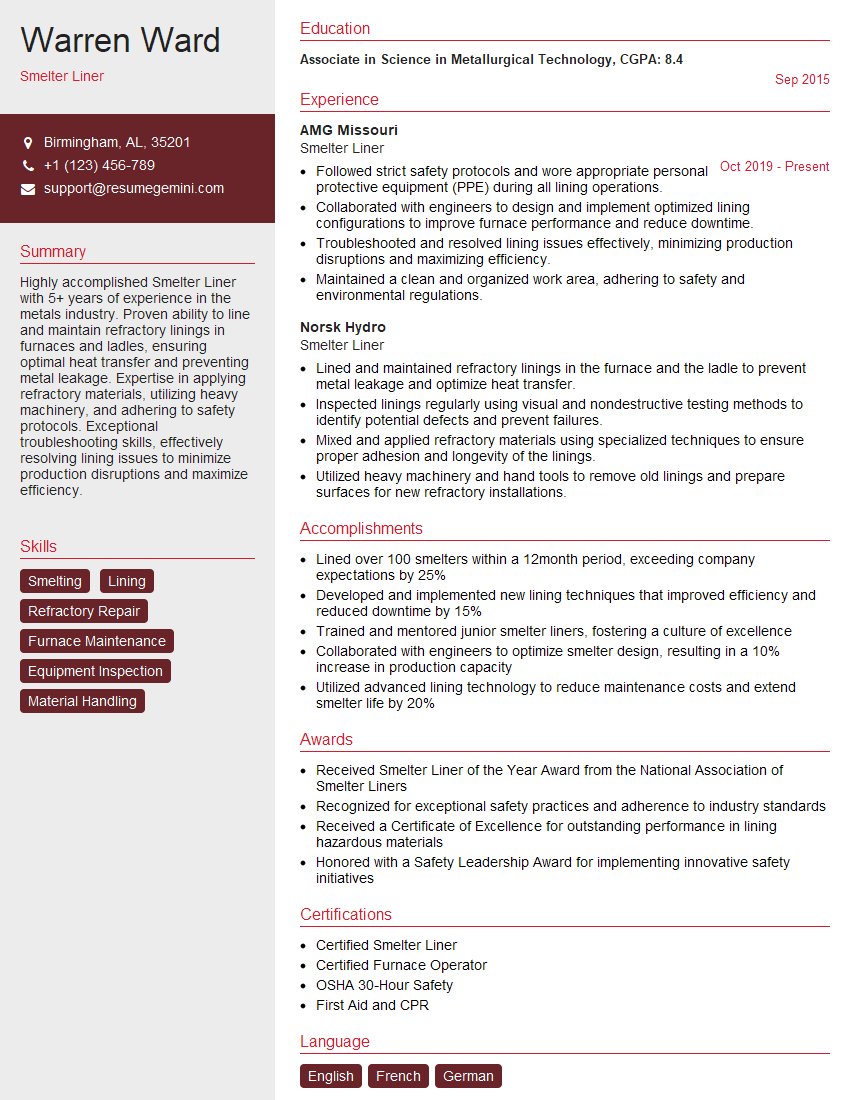

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Smelter Liner

1. Describe the primary responsibilities of a Smelter Liner?

- Installing and maintaining refractory linings in smelters, furnaces, and other high-temperature industrial equipment.

- Inspecting and evaluating the condition of linings to identify any damaged or worn areas.

- Mixing and applying refractory materials to repair or replace damaged linings.

- Operating and maintaining equipment used for refractory installation and repair, such as air cannons and gunning machines.

- Monitoring and controlling the temperature and other operating conditions of the equipment to ensure proper refractory performance.

2. What are the different types of refractory materials used in smelters?

Types of refractory materials

- Fireclay

- Magnesite

- Chrome

- Alumina

- Zirconia

Factors for choosing a particular material

- Temperature resistance

- Chemical resistance

- Physical strength

- Abrasion resistance

- Cost

3. What are the key safety considerations when working as a Smelter Liner?

- Wearing appropriate personal protective equipment (PPE), such as respirators, gloves, and protective clothing.

- Being aware of the potential hazards of working with high-temperature equipment and materials.

- Following established safety procedures and protocols.

- Working in a well-ventilated area to avoid exposure to harmful fumes or dust.

- Receiving proper training and certification before performing any hazardous tasks.

4. What are the troubleshooting techniques you use when encountering problems with refractory linings?

- Identifying and assessing the severity of the problem.

- Determining the root cause of the failure.

- Selecting and implementing appropriate repair or replacement strategies.

- Monitoring the performance of the repaired or replaced lining to ensure its effectiveness.

- Documenting the troubleshooting process and any corrective actions taken.

5. How do you stay up-to-date with the latest advancements in refractory materials and techniques?

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and discussion groups.

- Consulting with refractory manufacturers and suppliers.

- Receiving on-the-job training from experienced professionals.

6. Describe your experience in working with different types of metals and alloys.

- Listing the specific metals and alloys you have worked with.

- Describing your responsibilities and tasks related to each metal or alloy.

- Highlighting any specialized knowledge or skills you have developed.

- Explaining how your experience has contributed to your overall understanding of metal properties and behavior.

7. How do you handle working in a fast-paced and demanding environment?

- Describing your ability to prioritize tasks and manage time effectively.

- Explaining how you stay organized and focused under pressure.

- Highlighting your communication and teamwork skills.

- Providing examples of how you have successfully handled demanding situations in the past.

8. What are your career goals and aspirations?

- Expressing your interest in the Smelter Liner position.

- Describing your long-term career goals and aspirations.

- Explaining how this role aligns with your career path.

- Indicating your willingness to learn and grow within the organization.

9. Why should we hire you as a Smelter Liner?

- Summarizing your relevant skills and experience.

- Highlighting your qualifications that make you a suitable candidate for the role.

- Expressing your enthusiasm for the position and the organization.

- Convincing the interviewer that you are the best person for the job.

10. Do you have any questions for us?

- Asking thoughtful questions about the role and the organization.

- Demonstrating your interest in the position and the company.

- Showing that you are engaged and eager to learn more.

- Thanking the interviewer for their time and consideration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Smelter Liner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Smelter Liner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Smelter Liners play a vital role in the smelting process by ensuring the safe and efficient operation of the smelter. Their key responsibilities include:

1. Inspecting and Preparing the Smelter

Smelter Liners are responsible for inspecting the smelter regularly to identify any potential issues or areas that require repair. They prepare the smelter for operation by ensuring that the lining is properly installed and maintained to prevent leaks or damage.

- Checking the smelter’s lining for any cracks, holes, or other damage.

- Repairing or replacing damaged linings as needed.

- Ensuring that the smelter is properly ventilated and equipped with safety features.

2. Lining the Smelter

Smelter Liners are responsible for lining the smelter with refractory materials to protect it from the high temperatures and corrosive substances involved in the smelting process. They use specialized techniques to apply and shape the refractory materials to create a durable and effective lining.

- Selecting the appropriate refractory materials based on the specific smelting process.

- Applying the refractory materials using specialized techniques, such as spraying, troweling, or ramming.

- Ensuring that the lining is properly cured and dried before use.

3. Monitoring and Maintaining the Smelter

Smelter Liners are responsible for monitoring the smelter’s operation and performing regular maintenance tasks. They check for any signs of damage or wear and tear and take corrective actions as needed to ensure the smelter’s safe and efficient operation.

- Monitoring the smelter’s temperature, pressure, and other operating parameters.

- Performing routine inspections and maintenance tasks, such as cleaning, lubrication, and adjustments.

- Troubleshooting and resolving any operational issues that may arise.

4. Safety and Environmental Compliance

Smelter Liners are responsible for ensuring that the smelter is operated in a safe and environmentally compliant manner. They follow established safety protocols and procedures, and comply with all applicable regulations and standards.

- Wearing appropriate personal protective equipment (PPE) and following safety guidelines.

- Monitoring the smelter’s emissions and ensuring compliance with environmental regulations.

- Participating in safety training and drills.

Interview Tips

Preparing for an interview can help you showcase your skills and qualifications and increase your chances of success. Here are some tips to help you prepare for a Smelter Liner interview:

1. Research the Company and Position

Take the time to learn about the company you are applying to and the specific Smelter Liner position. This will help you understand the company’s culture, values, and the specific requirements of the job. You can research the company’s website, LinkedIn profile, and industry publications.

- Identify the company’s mission, values, and key products or services.

- Read the job description carefully and highlight the key skills and qualifications required.

2. Practice Answering Common Interview Questions

Prepare for some of the common interview questions you may encounter. Practice answering them out loud and consider using the STAR method (Situation, Task, Action, Result) to structure your responses. This method involves describing a specific situation, the task you were responsible for, the actions you took, and the results you achieved. Here are some examples of common interview questions for Smelter Liners:

- Tell me about your experience in lining and maintaining smelters.

- Describe a time when you had to troubleshoot and resolve a problem with a smelter.

- How do you ensure that the smelter is operated safely and in compliance with environmental regulations?

3. Highlight Your Relevant Skills and Experience

During the interview, focus on highlighting the skills and experience that are most relevant to the Smelter Liner position. Use specific examples to demonstrate your abilities and how they have benefited previous employers. Quantify your accomplishments whenever possible to provide tangible evidence of your results.

- Emphasize your experience in refractory materials and lining techniques.

- Provide examples of projects where you successfully maintained and repaired smelters.

- Showcase your knowledge of safety protocols and environmental compliance.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your understanding of the role and the company. This is also an opportunity to clarify any details or gain additional insights into the position and the company’s culture.

- Ask about the company’s plans for future growth or sustainability initiatives.

- Inquire about the training and development opportunities available to Smelter Liners.

- Seek information about the company’s safety record and commitment to environmental stewardship.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Be respectful and professional, and dress appropriately for the occasion. Your demeanor and presentation can significantly impact the interviewer’s perception of you and your candidacy for the position.

- Show your passion for the field of metallurgy and your eagerness to contribute to the success of the company.

- Maintain eye contact, speak clearly, and actively listen to the interviewer’s questions and responses.

- Thank the interviewer for their time and express your interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Smelter Liner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.