Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Smelting Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Smelting Engineer so you can tailor your answers to impress potential employers.

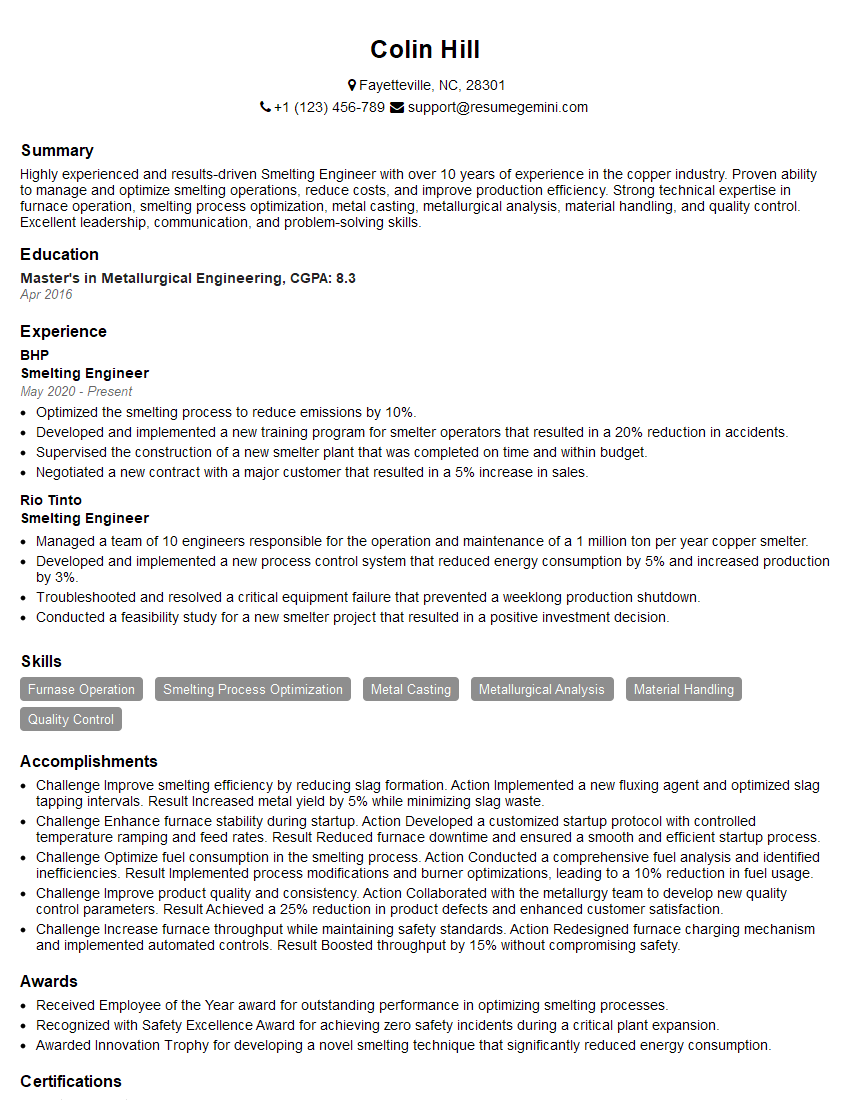

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Smelting Engineer

1. What are the key responsibilities of a Smelting Engineer?

As a Smelting Engineer, I am responsible for designing, operating, and maintaining smelting furnaces to extract valuable metals from ores and concentrates. This includes:

- Developing and optimizing smelting processes

- Monitoring and controlling furnace operation

- Troubleshooting and resolving furnace issues

- Ensuring compliance with environmental regulations

- Researching and developing new smelting technologies

2. What is the difference between a blast furnace and an electric arc furnace?

Blast Furnace

- Uses coke as a fuel source

- Produces molten iron

- Requires a large amount of energy

Electric Arc Furnace

- Uses electricity as a heat source

- Produces steel

- More energy-efficient than a blast furnace

3. What are the different types of flux used in smelting?

The different types of flux used in smelting include:

- Limestone (CaCO3)

- Dolomite (CaMg(CO3)2)

- Silica (SiO2)

- Fluorspar (CaF2)

Each type of flux has a specific purpose, such as removing impurities, reducing slag viscosity, and improving metal recovery.

4. What are the main factors that affect the efficiency of a smelting process?

The main factors that affect the efficiency of a smelting process include:

- Ore quality

- Furnace design

- Operating conditions

- Flux selection

- Energy input

5. What are the potential environmental concerns associated with smelting?

The potential environmental concerns associated with smelting include:

- Air pollution (e.g., sulfur dioxide, nitrogen oxides)

- Water pollution (e.g., heavy metals)

- Solid waste generation (e.g., slag, fly ash)

6. What are the key safety considerations for working in a smelter?

The key safety considerations for working in a smelter include:

- Wearing proper personal protective equipment

- Following safe work procedures

- Being aware of potential hazards

- Receiving regular training

7. What are the latest trends in smelting technology?

The latest trends in smelting technology include:

- The use of oxygen enrichment to increase furnace efficiency

- The development of new flux materials to improve metal recovery

- The use of automation and control systems to improve process stability

8. What are the different types of Smelting Furnaces?

The different types of smelting furnaces include:

- Blast furnaces

- Electric arc furnaces

- Induction furnaces

- Reverberatory furnaces

9. What are the key factors to consider when selecting a Smelting Furnace?

The key factors to consider when selecting a smelting furnace include:

- The type of ore to be smelted

- The desired production rate

- The available energy sources

- The environmental regulations

10. What are the common challenges faced by Smelting Engineers?

The common challenges faced by Smelting Engineers include:

- Maximizing metal recovery

- Minimizing energy consumption

- Reducing environmental impact

- Optimizing furnace performance

- Troubleshooting and resolving process issues

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Smelting Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Smelting Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Smelting Engineers are responsible for overseeing the smelting process, which involves extracting metal from ore. They work in a variety of industries, including mining, manufacturing, and recycling.

1. Design and Improve Smelting Processes

Smelting Engineers design and improve smelting processes to increase efficiency and reduce costs. They may also develop new smelting technologies.

- Conduct research to identify new ways to improve the smelting process.

- Design and test new smelting technologies.

2. Manage Smelting Operations

Smelting Engineers manage smelting operations to ensure that they are safe and efficient. They may also train and supervise smelting operators.

- Develop and implement operating procedures.

- Monitor and control the smelting process.

3. Troubleshoot Smelting Problems

Smelting Engineers troubleshoot smelting problems to identify and resolve issues that may arise during the smelting process.

- Identify the source of smelting problems.

- Develop and implement solutions to smelting problems.

4. Optimize Smelting Operations

Smelting Engineers optimize smelting operations to improve efficiency and reduce costs. They may also develop new smelting technologies.

- Monitor and analyze smelting data to identify areas for improvement.

- Develop and implement strategies to optimize smelting operations.

Interview Tips

Preparing for an Smelting Engineer interview can be a daunting task. However, by following the tips below, you can increase your chances of success.

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and products.

- Read articles about the company in the news and industry publications.

- Talk to people who work at the company to get their insights on the culture and the job.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked. By practicing answering these questions, you can feel more confident and prepared during your interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of an interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the job.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement within the company?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire.

- Be on time for your interview.

- Make eye contact and smile when you meet the interviewer.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Smelting Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.