Are you gearing up for a career in Smoking Pipe Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Smoking Pipe Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

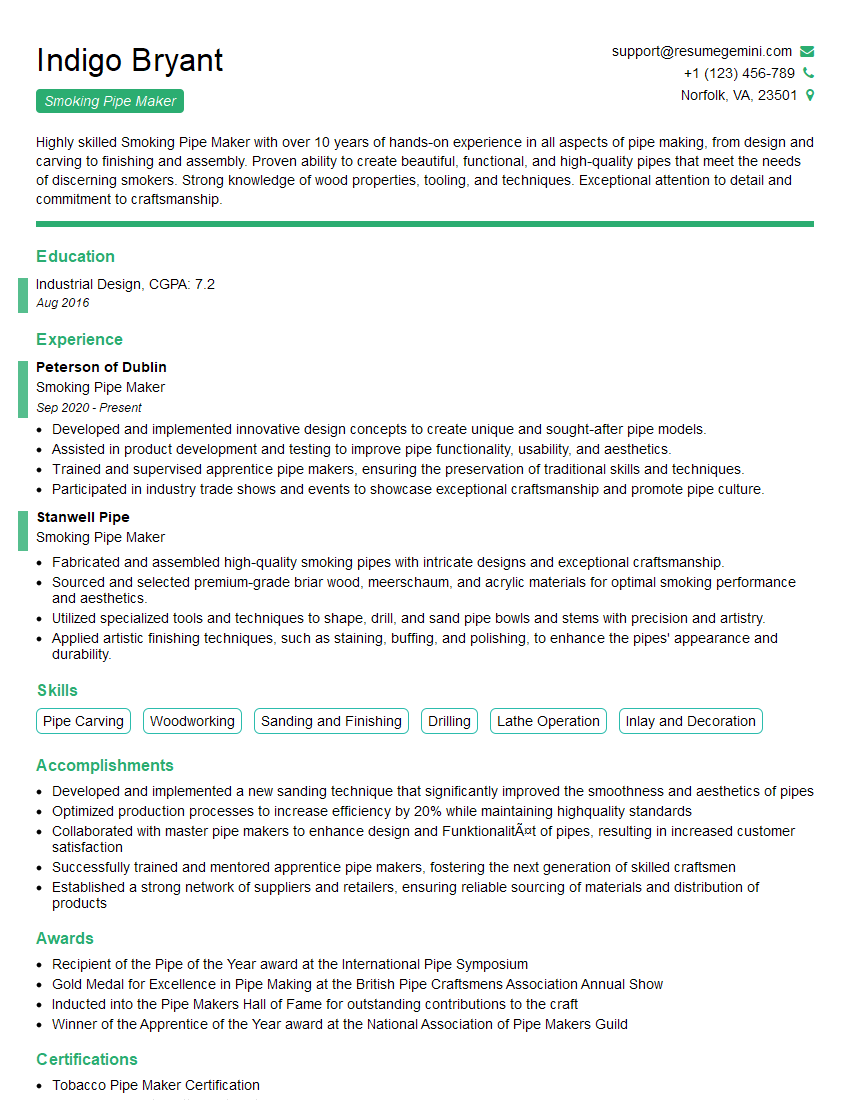

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Smoking Pipe Maker

1. Which types of wood are best suited for making smoking pipes, and why?

The choice of wood for smoking pipes depends on several factors, including its grain, density, heat resistance, and ability to absorb and release moisture. Some of the most common and suitable types of wood for pipe making include:

- Briarwood: A dense and heat-resistant wood with a fine grain and natural oils that help prevent moisture buildup.

- Mahogany: A reddish-brown hardwood with a straight grain and good heat resistance, known for its durability and rich color.

- Cherry: A reddish-brown wood with a close grain and good moisture absorption properties, resulting in a milder smoke.

- Olivewood: A dense and oily wood with a unique grain pattern, known for its durability and pleasant aroma.

- Ebony: A dense and black hardwood with a very fine grain, offering excellent heat resistance and a smooth finish.

2. Describe the process of curing and seasoning the wood for smoking pipes.

Curing

- The wood is initially air-dried or placed in a kiln to remove excess moisture.

- It is then stored in a controlled environment with specific temperature and humidity levels to allow the wood to stabilize dimensionally.

Seasoning

- The cured wood is subjected to another period of drying, usually in a controlled environment, to further reduce moisture content.

- This process enhances the wood’s stability, durability, and resistance to warping or cracking.

3. What are the different methods used to shape and carve the wood for smoking pipes?

Several methods can be used to shape and carve the wood for smoking pipes, including:

- Hand Carving: Using traditional hand tools such as chisels, gouges, and files to manually carve the desired shape from a block of wood.

- Machine Shaping: Employing lathes, milling machines, or CNC routers to shape the wood more precisely and efficiently.

- Sanding and Finishing: Smoothing and refining the carved surface using sandpaper, abrasives, and polishing compounds.

4. How do you ensure the proper drilling and fitting of the airway and stem for optimal airflow and draw resistance?

To achieve optimal airflow and draw resistance, meticulous drilling and fitting of the airway and stem are crucial:

- Drilling: The airway is drilled through the center of the pipe to allow for the passage of smoke.

- Stem Fitting: The stem is fitted into the tenon of the pipe body to create a tight seal and seamless airflow path.

- Testing: The pipe is tested to ensure proper draw resistance and airflow by smoking it or using a draw machine.

5. What are the essential steps involved in staining, finishing, and polishing the pipe to achieve a desired aesthetic?

- Staining: Applying a dye or stain to enhance the wood’s color and grain patterns.

- Finishing: Protecting the pipe’s surface with a sealant or finish, such as shellac, lacquer, or wax, to improve durability and aesthetics.

- Polishing: Using abrasive compounds and polishing cloths to bring out the shine and luster of the finish.

6. How do you assess the quality of a smoking pipe based on its design, materials, and craftsmanship?

Assessing the quality of a smoking pipe involves evaluating various factors:

- Design: Evaluating the overall shape, proportions, and functionality of the pipe.

- Materials: Assessing the quality and suitability of the wood and other materials used in its construction.

- Craftsmanship: Inspecting the precision of the drilling, fitting, and finishing, as well as the overall attention to detail.

7. Describe your understanding of different smoking pipe styles and their unique characteristics.

There are various smoking pipe styles, each with distinct characteristics:

- Classic Straight: A traditional style with a straight stem and a bowl that can vary in shape.

- Bent Billiard: A curved stem with a rounded bowl, providing a comfortable smoking experience.

- Bulldog: A short, thick-set style with a low-set bowl and a dog-like appearance.

- Poker: A straight-stemmed pipe with a cylindrical bowl, designed for a strong draw.

- Churchwarden: A long-stemmed pipe with a small bowl, offering a cool and distant smoke.

8. How do you stay updated on the latest trends and advancements in smoking pipe design and production techniques?

To stay current with industry developments, I engage in several practices:

- Attending Trade Shows: Visiting industry events to learn about new products, techniques, and trends.

- Reading Industry Publications: Subscribing to magazines and journals dedicated to smoking pipes.

- Networking with Other Pipe Makers: Connecting with experienced pipe makers to exchange knowledge and insights.

- Experimenting with New Materials and Techniques: Continuously exploring different materials, tools, and methods to enhance my craft.

9. How do you approach customizing a smoking pipe to meet the specific preferences of a client?

- Consultation: Engaging in a detailed discussion with the client to understand their preferences in terms of design, style, materials, and functionality.

- Design Process: Sketching out design concepts based on the client’s specifications and discussing options.

- Material Selection: Collaborating with the client to select the most suitable wood and other materials for their desired aesthetic and performance.

- Craftsmanship: Executing the design with precision, attention to detail, and adherence to the client’s vision.

- Quality Control: Rigorously testing and inspecting the finished pipe to meet the client’s expectations.

10. Describe a challenging project you encountered in smoking pipe making and how you overcame it.

- Challenge: Creating a highly intricate pipe with a complex design and multiple components.

- Solution: Breaking the project down into smaller, manageable tasks and carefully planning each step.

- Outcome: Successfully completing the pipe to the client’s satisfaction, showcasing exceptional craftsmanship and problem-solving abilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Smoking Pipe Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Smoking Pipe Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Smoking Pipe Makers are skilled artisans who create custom-made smoking pipes. They are responsible for all aspects of the pipe-making process, from selecting and preparing the wood to shaping and finishing the pipe. The key job responsibilities of a Smoking Pipe Maker include:

1. Wood Selection and Preparation

Smoking Pipe Makers must have a keen eye for selecting the right wood for their pipes. The wood must be of high quality, with a tight grain and a rich color. The wood must also be properly seasoned, so that it will not crack or warp when it is used.

- Selecting the right wood for the pipe

- Properly seasoning the wood

2. Shaping the Pipe

Once the wood has been selected and prepared, the Smoking Pipe Maker will begin shaping the pipe. This is a delicate process, as the shape of the pipe will affect its smoking characteristics. The Smoking Pipe Maker will use a variety of tools to shape the pipe, including knives, chisels, and sandpaper.

- Using a variety of tools to shape the pipe

- Creating a shape that will affect its smoking characteristics

3. Finishing the Pipe

Once the pipe has been shaped, the Smoking Pipe Maker will finish it. This includes sanding the pipe to smooth it out, staining or painting it, and adding any other decorative touches. The Smoking Pipe Maker may also carve or engrave the pipe with a design.

- Sanding the pipe to smooth it out

- Staining or painting the pipe

- Adding decorative touches

- Carving or engraving the pipe with a design

Interview Tips

When you are preparing for an interview for a Smoking Pipe Maker position, it is important to be prepared and to highlight your skills and experience. Here are a few tips to help you ace the interview:

1. Research the Company

Before you go to the interview, take some time to research the company and learn about their products and their history. This will show the interviewer that you are interested in the company and that you have taken the time to learn about them.

- Visit the company’s website

- Read articles about the company and its products

- Talk to people who work for the company

2. Practice Your Skills

Smoking Pipe Makers are skilled artisans, so it is important to be able to demonstrate your skills during the interview. If possible, bring a portfolio of your work to the interview. You can also show the interviewer your tools and explain how you use them to create your pipes.

- Bring a portfolio of your work to the interview

- Show the interviewer your tools

- Explain how you use your tools to create your pipes

3. Be Prepared to Talk About Your Experience

The interviewer will likely ask you about your experience in smoking pipe making. Be prepared to talk about your skills, your experience, and your knowledge of the industry. You should also be able to talk about your passion for smoking pipe making.

- Talk about your skills and experience

- Discuss your knowledge of the industry

- Share your passion for smoking pipe making

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This will show the interviewer that you are interested in the position and that you are serious about working for the company.

- Ask questions about the position

- Ask questions about the company

- Show that you are interested in the position and the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Smoking Pipe Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!