Are you gearing up for an interview for a Smoking Pipe Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Smoking Pipe Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

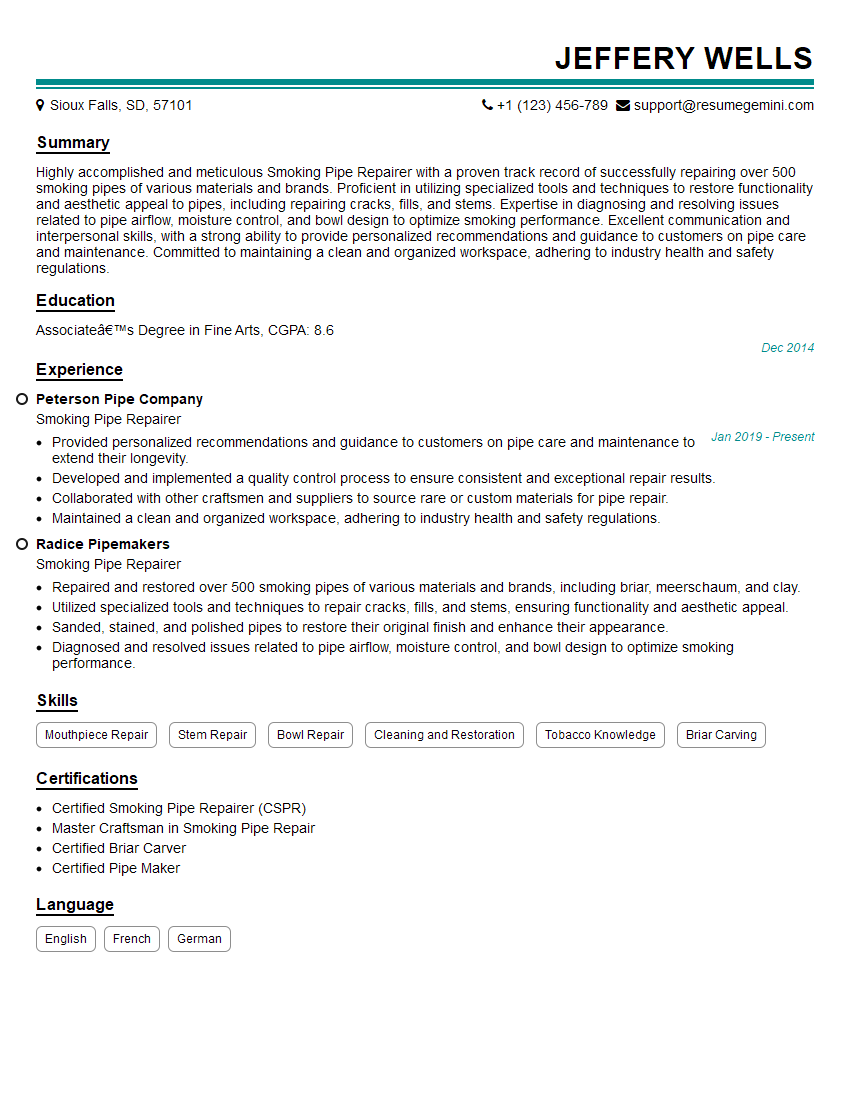

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Smoking Pipe Repairer

1. What are the common materials used in making smoking pipes, and how do their properties affect the smoking experience?

Materials used for smoking pipe craftsmanship include:

- Briarwood: Renowned for its heat resistance and durability, it’s the most common material for high-quality pipes.

- Meerschaum: A clay mineral that absorbs moisture and develops a beautiful patina over time, with a comfortable and cool smoke.

- Corn cob: Absorbent, inexpensive, and disposable, providing a mellow and flavorful smoke.

- Clay: Durable and affordable, but prone to breakage and absorbs moisture, affecting the smoke’s taste.

- Gourd: A natural material that provides a unique smoking experience, offering a cool and dry smoke.

2. Describe the process of creating a handmade smoking pipe from start to finish.

Selecting and Preparing the Material

- Choosing a suitable block of briar, meerschaum, or other material.

- Roughly shaping the block to remove excess material.

- Drilling the airway and tobacco chamber.

Carving and Shaping

- Fine-tuning the pipe’s shape using a variety of tools.

- Creating the bowl, shank, and mouthpiece.

- Sanding and smoothing the surface.

Finishing and Assembling

- Applying a finish, such as wax or stain, to protect and enhance the pipe’s appearance.

- Fitting the mouthpiece to the shank.

- Polishing and inspecting the finished pipe.

3. What are the different types of smoking pipe finishes, and how do they impact the pipe’s appearance and performance?

- Natural: Preserves the original color and grain of the wood, providing a classic and rustic look.

- Stained: Alters the color of the wood, enhancing its appearance and protecting it from moisture.

- Waxed: Seals the wood’s pores, providing a protective layer and enhancing the grain’s depth.

- Lacquered: Creates a glossy and durable finish, protecting the pipe from wear and tear.

- Sandblasted: Renders a textured surface, adding a rustic and unique touch while improving grip.

4. How do you diagnose and repair common smoking pipe issues, such as stem damage, airway blockage, and bowl cracks?

Stem Damage

- Inspect the stem for cracks or chips.

- Use a stem repair kit to fill in any gaps or cracks.

- Sand and polish the repaired area to blend it with the original stem.

Airway Blockage

- Clear the airway with a pipe cleaner or compressed air.

- Check for any obstructions, such as tobacco debris or foreign objects.

- If necessary, disassemble the pipe and clean the airway thoroughly.

Bowl Cracks

- Identify the extent of the crack.

- Fill the crack with a suitable adhesive, such as super glue or epoxy.

- Clamp the pipe together and allow the adhesive to dry completely.

- Sand and polish the repaired area to restore the pipe’s appearance.

5. What are the different types of smoking pipe mouthpieces, and how do they affect the smoking experience?

- Acrylic: Lightweight, comfortable to bite, and resistant to heat and moisture.

- Ebonite: Made from hard rubber, it’s durable and provides a warm and comfortable feel.

- Cumberland: A black material made from a combination of rubber and vulcanite, offering a classic and sophisticated look.

- Delrin: A lightweight and durable plastic, providing a smooth and comfortable bite.

- Amber: A natural material that’s lightweight, warm to the touch, and absorbs moisture to improve the smoke’s flavor.

6. How do you maintain and clean smoking pipes to ensure optimal smoking performance and longevity?

- Use a pipe cleaner to remove tobacco debris after each smoke.

- Clean the pipe with a pipe reamer and brush regularly to remove any buildup.

- Periodically disassemble the pipe and clean it thoroughly with rubbing alcohol.

- Allow the pipe to dry completely before reassembling and smoking.

- Store pipes in a cool, dry place to prevent moisture buildup and warping.

7. What are the safety precautions that should be taken when working with smoking pipes?

- Always handle sharp tools with care.

- Wear safety glasses when cutting or sanding.

- Use a well-ventilated workspace to avoid inhaling dust or fumes.

- Never smoke a pipe that has been repaired with toxic materials.

- Follow proper disposal methods for used pipe cleaners and tobacco.

8. Describe the different techniques used to carve smoking pipes, such as freehand, rustication, and sandblasting.

Freehand

- Involves carving the pipe without using any pre-made shapes or templates.

- Requires a high level of skill and experience.

- Results in unique and artistic pipes.

Rustication

- Creates a textured surface on the pipe by scraping or sanding the wood.

- Enhances the pipe’s grip and provides a rugged appearance.

- Can be done by hand or with a machine.

Sandblasting

- Uses compressed air to blast sand or other abrasive materials at the pipe’s surface.

- Creates a matte and porous finish.

- Improves the pipe’s grip and reduces the risk of chipping.

9. What are the key factors to consider when selecting a smoking pipe for a customer?

- Purpose: Determine the intended use, whether for daily smoking or special occasions.

- Material: Discuss the differences between briarwood, meerschaum, and other materials.

- Shape and Size: Guide the customer based on their preferences and comfort level.

- Finish: Explain the various finishes available and their impact on appearance and performance.

- Budget: Determine the customer’s budget and offer appropriate recommendations.

10. Describe the qualities and skills that you believe are essential for a successful smoking pipe repairer.

- Technical Expertise: Strong understanding of pipe construction, materials, and repair techniques.

- Dexterity and Precision: Ability to perform delicate and precise repairs with precision tools.

- Problem-Solving Abilities: Skills in diagnosing and resolving various pipe issues.

- Attention to Detail: Meticulous approach to ensure the highest quality of repairs.

- Customer Service Orientation: Friendly and professional communication with customers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Smoking Pipe Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Smoking Pipe Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Smoking Pipe Repairers are skilled craftspeople responsible for restoring and repairing smoking pipes. They possess a deep understanding of pipe anatomy and use specialized tools and techniques to preserve the integrity and functionality of these valuable items.

1. Pipe Assessment

Inspect and evaluate pipes to determine the extent of damage or required repairs. Identify structural issues, cracks, chips, and other defects.

- Use magnifying glasses and specialized instruments for detailed examination.

- Test pipes for functionality and airflow to assess any underlying problems.

2. Repair Techniques

Employ various repair techniques to restore pipes to their original condition. Utilize tools like drills, saws, and grinders to reshape, rebuild, or reattach damaged components.

- Repair cracks and chips using specialized adhesives and fillers.

- Reconstructive work, such as carving custom stems or replacing lost parts.

3. Refinishing and Restoration

Restore pipes to their original appearance and preserve their value. Perform tasks like sanding, staining, and polishing to enhance the aesthetic appeal.

- Remove dents and scratches to maintain the pipe’s smooth exterior.

- Apply protective coatings to prevent damage and extend the pipe’s life.

4. Client Communication

Communicate effectively with clients to understand their repair needs and expectations. Provide clear explanations of the repair process and offer recommendations.

- Discuss pricing, timelines, and any potential limitations.

- Keep clients informed about the progress of the repair.

Interview Tips

To ace your interview for a Smoking Pipe Repairer position, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and the smoking pipe industry. This demonstrates your interest and enthusiasm for the field.

- Visit the company’s website and social media pages.

- Read articles and industry publications to stay up-to-date on trends.

2. Highlight Your Skills and Experience

Emphasize your technical skills in pipe repair, including any specialized techniques or tools you are proficient in. Highlight your artistic abilities and attention to detail.

- Quantify your accomplishments whenever possible to demonstrate your impact.

- Be prepared to discuss specific examples of complex repairs you have handled.

3. Showcase Your Passion and Commitment

Convey your genuine interest in smoking pipes and pipe culture. Share your knowledge about different pipe styles, materials, and collecting trends.

- Discuss your personal collection or experience smoking pipes.

- Be enthusiastic and express your desire to learn and contribute to the industry.

4. Prepare Questions for the Interviewer

Show your engagement and professional curiosity by preparing thoughtful questions for the interviewer. This indicates your interest in the company and the role.

- Ask about the company’s repair philosophy and the types of pipes they commonly work on.

- Inquire about the training and advancement opportunities available.

Next Step:

Now that you’re armed with the knowledge of Smoking Pipe Repairer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Smoking Pipe Repairer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini