Feeling lost in a sea of interview questions? Landed that dream interview for Snuff Packing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Snuff Packing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

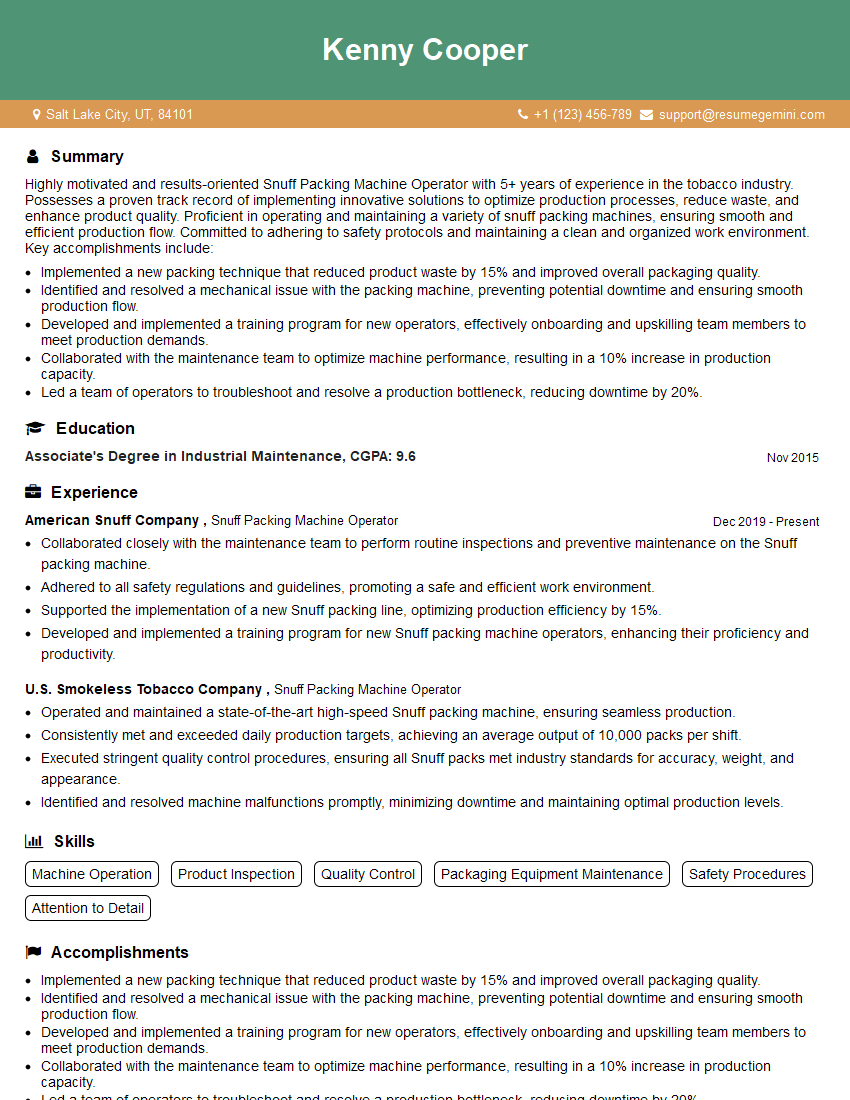

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Snuff Packing Machine Operator

1. Describe the steps involved in operating a snuff packing machine.

Sure, here are the steps involved in operating a snuff packing machine,

- Prepare the machine: This includes ensuring that the machine is clean and properly calibrated, and that all the necessary materials are on hand.

- Load the snuff: The snuff is typically loaded into a hopper or magazine on the machine.

- Set the machine parameters: This includes setting the speed of the machine, the fill weight, and the type of packaging being used.

- Start the machine: Once the machine is set up, it can be started to begin filling and sealing the packages.

- Monitor the machine: The operator should monitor the machine while it is running to ensure that it is operating properly and that the packages are being filled and sealed correctly.

- Unload the finished packages: Once the machine has finished filling and sealing the packages, the operator can unload them and prepare them for shipment.

2. What are the different types of snuff packing machines?

- Vertical Form Fill Seal (VFFS) machines: These machines form a tube of packaging material around the product, fill it with the product, and then seal the ends.

- Horizontal Form Fill Seal (HFFS) machines: These machines form a pouch of packaging material, fill it with the product, and then seal the edges.

- Pre-made pouch filling machines: These machines fill pre-made pouches with the product and then seal the pouches.

3. What are the most common problems that can occur with snuff packing machines?

Some of the most common problems that can occur with snuff packing machines include:

- Jams: Jams can occur when the product is not flowing properly through the machine.

- Leaks: Leaks can occur if the packages are not sealed properly.

- Incorrect fill weight: The fill weight can be incorrect if the machine is not calibrated properly.

- Machine breakdowns: Machine breakdowns can occur for a variety of reasons, such as electrical problems or mechanical failures.

4. How do you troubleshoot a snuff packing machine?

Troubleshooting a snuff packing machine typically involves the following steps:

- Identify the problem: The first step is to identify the problem with the machine. This can be done by observing the machine while it is running and looking for any obvious problems.

- Check the machine parameters: Once the problem has been identified, the next step is to check the machine parameters to make sure that they are set correctly.

- Inspect the machine: The next step is to inspect the machine for any damage or wear. This can be done by looking for any loose or damaged parts, as well as any build-up of product or debris.

- Clean the machine: If the machine is dirty, it can be cleaned using a mild detergent and water. It is important to make sure that the machine is completely dry before restarting it.

- Lubricate the machine: The machine should be lubricated regularly to ensure that it is operating smoothly. It is important to use a lubricant that is specifically designed for use on snuff packing machines.

- Restart the machine: Once the problem has been resolved, the machine can be restarted and tested to make sure that it is operating properly.

5. What are the safety precautions that must be taken when operating a snuff packing machine?

- Wear appropriate safety gear: When operating a snuff packing machine, it is important to wear appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- Be aware of your surroundings: It is important to be aware of your surroundings when operating a snuff packing machine. This includes being aware of any moving parts, as well as any potential hazards.

- Follow the manufacturer’s instructions: It is important to follow the manufacturer’s instructions when operating a snuff packing machine. This includes following the instructions for starting, stopping, and cleaning the machine.

- Report any problems: If you encounter any problems with the snuff packing machine, it is important to report them to your supervisor immediately.

6. How do you maintain a snuff packing machine?

Maintaining a snuff packing machine involves the following tasks:

- Cleaning the machine: The machine should be cleaned regularly to prevent the build-up of product or debris. It is important to use a mild detergent and water when cleaning the machine, and to make sure that the machine is completely dry before restarting it.

- Lubricating the machine: The machine should be lubricated regularly to ensure that it is operating smoothly. It is important to use a lubricant that is specifically designed for use on snuff packing machines.

- Inspecting the machine: The machine should be inspected regularly for any damage or wear. This can be done by looking for any loose or damaged parts, as well as any build-up of product or debris.

- Calibrating the machine: The machine should be calibrated regularly to ensure that it is filling and sealing the packages correctly. This can be done by using a weight scale to check the fill weight of the packages, and by using a leak detector to check the seal quality of the packages.

7. What is the importance of preventive maintenance for snuff packing machines?

Preventive maintenance is important for snuff packing machines because it can help to prevent unexpected breakdowns and extend the life of the machine. By regularly cleaning, lubricating, and inspecting the machine, you can help to identify and correct potential problems before they cause major damage.

8. What are the different types of snuff packaging materials?

- Paper: Paper is a common material used for snuff packaging. It is relatively inexpensive and easy to work with.

- Plastic: Plastic is another common material used for snuff packaging. It is durable and moisture-resistant, making it a good choice for packaging snuff that will be exposed to moisture.

- Metal: Metal is a less common material used for snuff packaging. It is durable and moisture-resistant, but it is also more expensive than paper or plastic.

9. What are the factors to consider when choosing a snuff packaging material?

- The type of snuff: The type of snuff that you are packaging will determine the type of packaging material that you need. For example, if you are packaging a moist snuff, you will need a material that is moisture-resistant.

- The packaging process: The packaging process that you are using will also determine the type of packaging material that you need. For example, if you are using a VFFS machine, you will need a material that is flexible and easy to form.

- The cost: The cost of the packaging material is also an important factor to consider. You will need to find a material that is affordable and that fits within your budget.

10. What are the latest trends in snuff packaging?

- Sustainable packaging: There is a growing trend towards using sustainable packaging materials for snuff. This includes using materials that are recyclable, biodegradable, or compostable.

- Innovative packaging designs: Snuff manufacturers are also using innovative packaging designs to attract consumers. This includes using unique shapes, colors, and graphics.

- Personalized packaging: Snuff manufacturers are also offering personalized packaging options to consumers. This allows consumers to create their own custom snuff packages.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Snuff Packing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Snuff Packing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Snuff Packing Machine Operator is responsible for the operation and maintenance of snuff packing machines. They ensure that the machines are running smoothly and efficiently, and that the snuff is packed to the correct specifications. Key job responsibilities include:Loading the snuff into the machine.

1. Operating the machine

Starting and stopping the machine.

Adjusting the machine settings to ensure that the snuff is packed to the correct specifications.

Monitoring the machine to ensure that it is running smoothly.

2. Maintaining the machine

Cleaning and lubricating the machine.

Inspecting the machine for wear and tear.

Performing minor repairs.

3. Troubleshooting

Identifying and resolving problems with the machine.

4. Quality control

Inspecting the packed snuff to ensure that it meets quality standards.

Interview Tips

To prepare for an interview for a Snuff Packing Machine Operator position, you should:

1. Research the company

Learn about the company’s history, products, and culture.

2. Practice answering common interview questions

Prepare answers to questions about your experience, skills, and qualifications. Use the STAR method to answer interview questions. STAR stands for Situation, Task, Action, Result. When answering using the STAR method, you should provide a brief description of the situation, the task you were responsible for, the actions you took, and the results of your actions.

3. Prepare questions to ask the interviewer

This shows that you are interested in the position and the company.

4. Dress professionally

First impressions matter. Dress appropriately for the interview.

5. Be on time

Punctuality is important. Arrive on time for your interview.

6. Be confident

Believe in yourself and your abilities. Confidence is key in an interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Snuff Packing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.