Feeling lost in a sea of interview questions? Landed that dream interview for Socket Welder Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Socket Welder Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

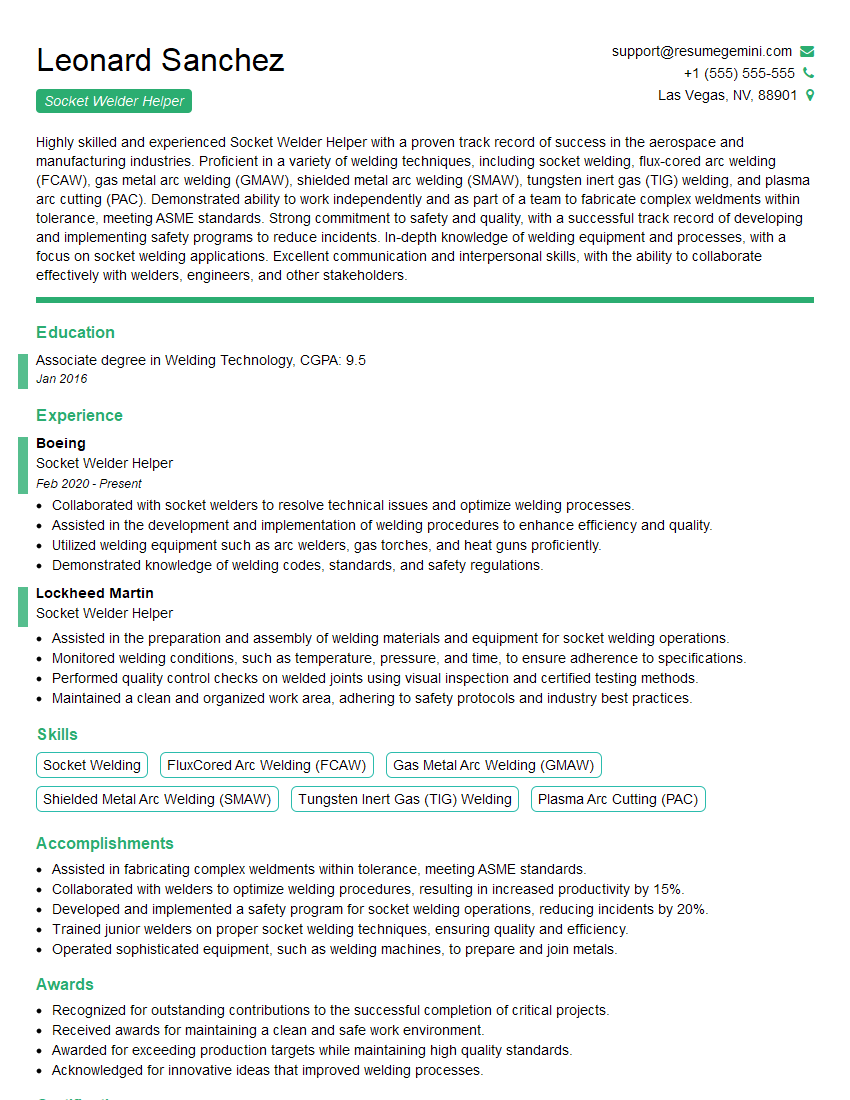

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Socket Welder Helper

1. Explain your understanding of the role and responsibilities of a Socket Welder Helper.

As a Socket Welder Helper, I would be responsible for assisting the Socket Welder in the welding process. This would include tasks such as:

- Preparing materials for welding, including cutting, cleaning, and aligning materials.

- Assisting the welder during the welding process by holding materials or operating welding equipment.

- Cleaning up the welding area after the welding process is complete.

- Checking welded joints for defects and ensuring they meet quality standards.

- Maintaining and cleaning welding equipment and tools.

2. Describe the different types of welding processes you are familiar with.

Arc Welding

- MIG Welding (Metal Inert Gas)

- TIG Welding (Tungsten Inert Gas)

- Stick Welding (Shielded Metal Arc Welding)

Oxy-Fuel Welding

- OAW (Oxy-Acetylene Welding)

- OFC (Oxy-Fuel Cutting)

3. Explain the importance of proper joint preparation before welding.

Proper joint preparation is critical for ensuring the quality and strength of the welded joint. It involves preparing the surfaces to be welded by cleaning them, removing any contaminants, and ensuring they are properly aligned. This helps to create a strong and uniform weld that is less likely to fail.

4. What are some common defects that can occur in welded joints, and how can they be prevented?

Some common defects that can occur in welded joints include:

- Porosity: Caused by gas bubbles trapped in the weld

- Slag Inclusions: Caused by pieces of slag becoming trapped in the weld

- Undercut: Caused by the weld metal not fully penetrating the base metal

- Overlapping: Caused by the weld metal flowing over the edges of the joint

These defects can be prevented by using proper welding techniques, ensuring proper joint preparation, and using the correct welding equipment and materials.

5. Describe the different types of welding equipment you have experience using.

I have experience using a variety of welding equipment, including:

- Welding machines (MIG, TIG, Stick)

- Plasma cutters

- Oxy-fuel torches

- Welding positioners

- Welding safety equipment

6. Explain the importance of following safety protocols while working as a Socket Welder Helper.

Following safety protocols is essential for ensuring the safety of myself and others in the workplace. These protocols include:

- Wearing appropriate personal protective equipment (PPE), including a welding helmet, gloves, and flame-resistant clothing.

- Ensuring the welding area is well-ventilated to prevent the accumulation of harmful fumes.

- Properly grounding welding equipment to prevent electrical shocks.

- Keeping the welding area clean and free of flammable materials.

- Following proper lifting techniques to prevent injuries.

- Being aware of the potential hazards of welding, such as burns, eye damage, and respiratory problems.

7. Describe a situation where you had to troubleshoot a welding problem.

I once encountered a situation where the welds were not penetrating the base metal properly. After troubleshooting the issue, I discovered that the welding machine was not set to the correct voltage and amperage. I adjusted the settings, and the welds began to penetrate properly.

8. Explain how you would ensure the quality of welded joints.

I would ensure the quality of welded joints by:

- Properly preparing the joint surfaces

- Using the correct welding technique and equipment

- Following the specified welding procedures

- Inspecting the welds for defects

- Testing the welds to ensure they meet the required standards

9. Describe your experience working in a team environment.

I have extensive experience working in a team environment. In my previous role as a Socket Welder Helper, I was responsible for working with a team of welders to complete various welding projects. I was able to communicate effectively with my team members, share ideas, and work together to achieve our goals.

10. Why are you interested in this Socket Welder Helper position?

I am interested in this Socket Welder Helper position because I am passionate about welding and I am eager to learn more about the trade. I am confident that I have the skills and experience necessary to be successful in this role, and I am excited about the opportunity to contribute to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Socket Welder Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Socket Welder Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Socket Welder Helpers play a vital role in the welding process, assisting the Socket Welder in various tasks related to the fabrication and installation of piping systems. Their key responsibilities include:

1. Material Preparation

Socket Welder Helpers assist in preparing welding materials, including cutting and beveling pipes, and ensuring proper fit-up to meet specifications.

2. Equipment Maintenance

They are responsible for maintaining and inspecting welding equipment, including grinders, torches, and safety gear, to ensure safe and efficient operation.

3. Assisting in Welding

Helpers assist the Socket Welder in operating welding equipment, holding and positioning workpieces, and ensuring the quality of welds by observing the welding process and reporting any irregularities.

4. Clean-up and Inspection

After welding is complete, Socket Welder Helpers are responsible for cleaning up the work area, removing slag and debris, and performing visual inspections of welded joints.

Interview Tips

To effectively prepare for an interview as a Socket Welder Helper, consider the following tips:

1. Research the Company and Role

Understand the company’s industry, values, and the specific requirements of the Socket Welder Helper position. This demonstrates your interest and enthusiasm for the opportunity.

2. Practice Your Welding Knowledge

Review basic welding principles and techniques. Be prepared to discuss your understanding of different welding processes, such as socket welding, and your experience with welding equipment.

3. Highlight Your Safety Awareness

Emphasize your commitment to safety on the job. Discuss your understanding of welding safety protocols and your experience in following safety regulations.

4. Showcase Your Teamwork Abilities

Socket Welder Helpers often work closely with other tradespeople. Highlight your ability to collaborate effectively, communicate clearly, and contribute to a positive work environment.

5. Prepare Questions

Asking thoughtful questions demonstrates your engagement and interest in the position. Prepare questions related to the company’s welding practices, safety procedures, or the specific responsibilities of the Socket Welder Helper.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Socket Welder Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.