Feeling lost in a sea of interview questions? Landed that dream interview for Solar Fabrication Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Solar Fabrication Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

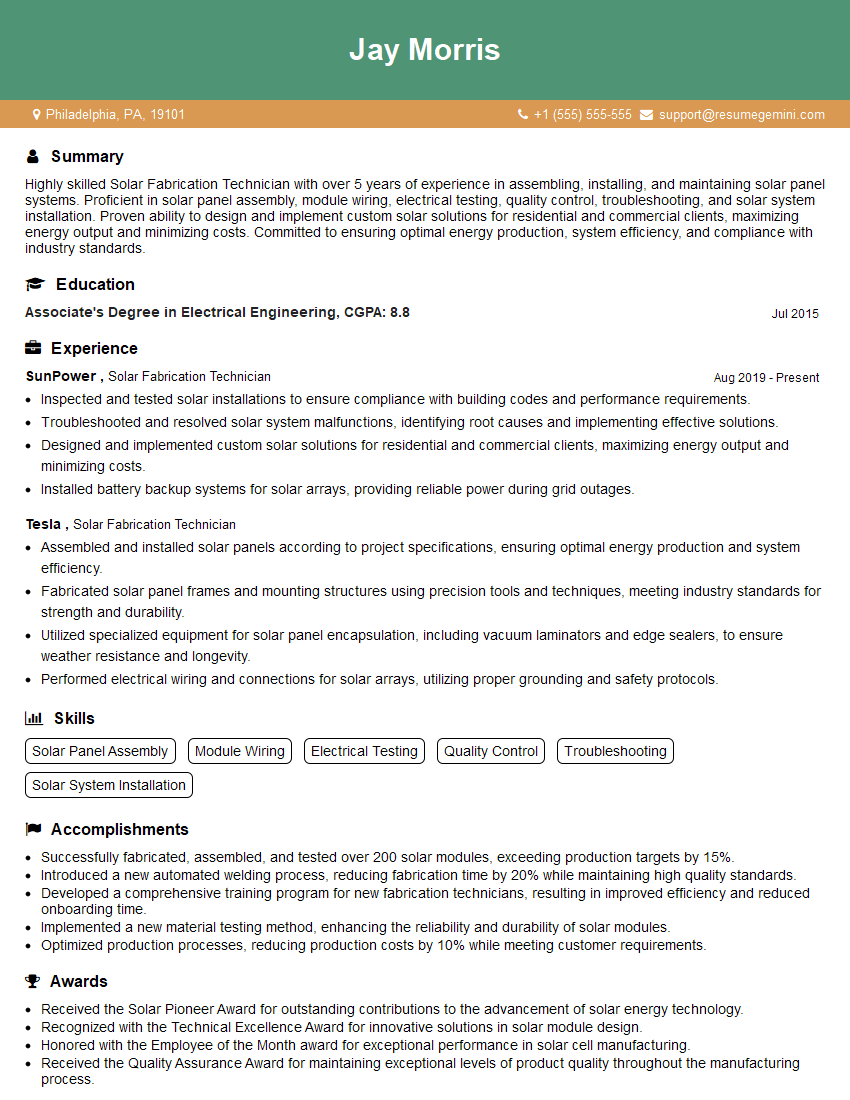

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Solar Fabrication Technician

1. Explain the process of solar panel fabrication, from start to finish.

The process of solar panel fabrication involves the following steps:

- Silicon Refining: The process begins with the purification of silicon, which is the primary material used in solar cells. The silicon is melted and then purified using a process called the Czochralski method.

- Wafer Production: The purified silicon is then sliced into thin wafers, which are the building blocks of solar cells.

- Cell Formation: The wafers are then treated with various chemicals and processes to create the solar cells. This involves depositing layers of materials on the wafers, such as an anti-reflective coating, a P-N junction, and metal contacts.

- Panel Assembly: The individual solar cells are then connected together to form a solar panel. The panels are typically framed and covered with a protective glass or polymer layer.

- Quality Control: The finished solar panels are then tested to ensure they meet the desired performance and quality standards.

2. What are the different types of solar cells?

Crystalline Silicon Solar Cells

- Monocrystalline silicon solar cells are the most efficient type of solar cell, with efficiencies of up to 25%. They are made from a single crystal of silicon.

- Polycrystalline silicon solar cells are less efficient than monocrystalline cells, but they are also less expensive. They are made from multiple crystals of silicon.

Thin-Film Solar Cells

- Thin-film solar cells are made from a thin layer of semiconductor material, such as cadmium telluride or copper indium gallium selenide. They are less efficient than crystalline silicon cells, but they are also less expensive and can be used in a wider variety of applications.

Emerging Solar Cell Technologies

- Perovskite solar cells are a new type of solar cell that has the potential to be more efficient and less expensive than traditional solar cells. They are made from a material called perovskite, which is a compound of calcium, titanium, and oxygen.

- Organic solar cells are made from organic materials, such as polymers or small molecules. They are lightweight and flexible, and they can be manufactured at a low cost.

3. What are the factors that affect the efficiency of a solar panel?

- Cell efficiency: The efficiency of the solar cells used in the panel.

- Panel design: The way the solar cells are arranged in the panel.

- Shading: The amount of shading that the panel is exposed to.

- Temperature: The temperature at which the panel is operating.

- Age: The age of the panel.

4. What are the different types of solar panel mounting systems?

- Ground-mounted systems: These systems are mounted on the ground, typically on a concrete or steel frame. They are usually used for large-scale solar installations.

- Roof-mounted systems: These systems are mounted on the roof of a building. They are typically used for residential and commercial installations.

- Pole-mounted systems: These systems are mounted on a pole. They are typically used for small-scale installations, such as streetlights and traffic signs.

5. What are the safety precautions that must be taken when working with solar panels?

- Electrical hazards: Solar panels generate electricity, so it is important to take precautions to avoid electrical shocks. This includes wearing proper safety gear, such as gloves and insulated tools.

- Fall hazards: Solar panels are often installed on roofs or other elevated surfaces. It is important to take precautions to avoid falls, such as using a harness and lifeline.

- Eye hazards: The sun’s rays can be harmful to the eyes. It is important to wear sunglasses or other eye protection when working with solar panels.

6. What are the maintenance requirements for solar panels?

- Regular cleaning: Solar panels should be cleaned regularly to remove dirt and debris. This will help to ensure optimal performance.

- Inspection: Solar panels should be inspected regularly for any damage or defects. This will help to prevent any potential problems.

- Repairs: If any damage or defects are found, they should be repaired promptly. This will help to ensure the continued performance of the solar panels.

7. What are the advantages and disadvantages of using solar energy?

Advantages

- Renewable: Solar energy is a renewable source of energy, which means that it will not run out.

- Clean: Solar energy does not produce any emissions, so it is a clean source of energy.

- Cost-effective: Solar energy is becoming increasingly cost-effective, and it is now a competitive option for many applications.

Disadvantages

- Intermittent: Solar energy is intermittent, which means that it is not available at all times. This can be a disadvantage for applications that require a constant source of energy.

- Land requirements: Solar panels require a large amount of land to generate a significant amount of electricity. This can be a disadvantage in areas with limited land availability.

8. What are the different types of solar applications?

- Grid-connected systems: These systems are connected to the electrical grid. They can provide electricity to the grid or to the building that they are installed on.

- Off-grid systems: These systems are not connected to the electrical grid. They typically use batteries to store electricity for use when the sun is not shining.

- Solar thermal systems: These systems use solar energy to heat water or air. They can be used for space heating, water heating, or industrial processes.

9. What are the latest trends in solar energy?

- Increased efficiency: Solar panels are becoming more and more efficient, which means that they can generate more electricity from the same amount of sunlight.

- Decreased cost: The cost of solar panels has been decreasing steadily over the past few years. This is making solar energy more affordable for more people.

- New technologies: New solar technologies are being developed all the time. These technologies have the potential to make solar energy even more efficient, affordable, and versatile.

10. What are your career goals?

My career goal is to become a Solar Fabrication Technician. I am passionate about renewable energy and I believe that solar energy has the potential to make a significant contribution to our future energy needs. I am eager to learn more about solar panel fabrication and I am confident that I have the skills and experience to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Solar Fabrication Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Solar Fabrication Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Solar Fabrication Technicians play a pivotal role in the manufacturing process of solar photovoltaic (PV) panels, ensuring the production of high-quality components for renewable energy systems. Their key responsibilities encompass:

1. Panel Assembly

Technicians meticulously assemble solar panels by connecting individual solar cells into modules, employing specialized equipment and adhering to precise specifications.

2. Quality Control

They conduct rigorous quality checks throughout the fabrication process, inspecting raw materials, components, and finished products to ensure compliance with industry standards and customer requirements.

3. Troubleshooting and Repair

They diagnose and resolve issues that arise during production, maintaining equipment and machinery, and promptly addressing any defects or malfunctions.

4. Materials Handling

Technicians efficiently manage and transport raw materials, components, and finished products within the production facility, adhering to safety protocols and optimizing workflow.

Interview Tips

To ace an interview for a Solar Fabrication Technician position, candidates should consider the following preparation tips:

1. Research the Industry

Demonstrate a deep understanding of the solar energy industry, its latest advancements, and the specific manufacturing processes employed by the company.

2. Highlight Relevant Skills

Emphasize proficiency in electrical circuitry, soldering techniques, quality control methodologies, and equipment operation.

3. Prepare for Technical Questions

Anticipate questions related to solar cell technology, panel assembly procedures, and troubleshooting techniques. Provide specific examples to showcase your expertise.

4. Showcase Safety Knowledge

Underscore your commitment to workplace safety by highlighting your knowledge of relevant regulations, hazard identification, and safe handling practices.

5. Practice Your Communication

Clearly articulate your technical skills, problem-solving abilities, and attention to detail. Practice answering questions confidently and concisely.

6. Dress Professionally

First impressions matter. Dress in appropriate business attire that conveys your professionalism and respect for the interviewer.

7. Be Prepared to Ask Questions

Show genuine interest in the company and the position by asking thoughtful questions about the production process, career growth opportunities, and the company’s commitment to sustainability.

8. Follow Up Promptly

After the interview, send a thank-you note to the interviewer within 24 hours. Express your appreciation for their time and reiterate your qualifications for the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Solar Fabrication Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.