Feeling lost in a sea of interview questions? Landed that dream interview for Solar Process Engineer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Solar Process Engineer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

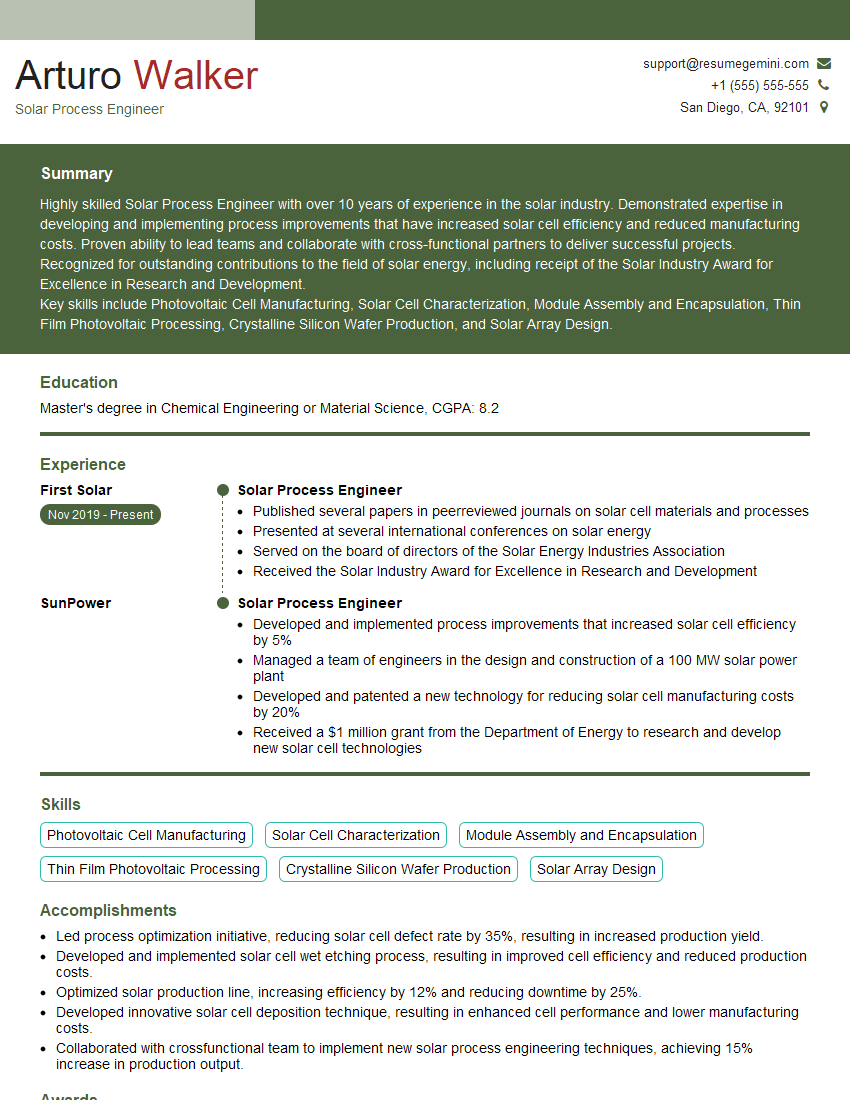

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Solar Process Engineer

1. Describe the key steps involved in the manufacturing process of a crystalline silicon solar cell?

The key steps involved in the manufacturing process of a crystalline silicon solar cell are as follows:

- Silicon Ingot Growth: Growing a single-crystal silicon ingot using the Czochralski or float zone method.

- Wafering: Slicing the silicon ingot into thin wafers using a diamond saw.

- Surface Texturing: Creating a textured surface on the wafers using chemical etching or laser ablation to enhance light absorption.

- Diffusion: Doping the wafers with phosphorus (n-type) on one side and boron (p-type) on the other side to create a p-n junction.

- Anti-Reflection Coating: Applying an anti-reflective coating to the front surface of the solar cell to minimize light reflection and increase absorption.

- Metallization: Screen-printing or depositing metal contacts (usually silver) on the front and back surfaces of the solar cell to collect and conduct electricity.

- Sintering: Firing the solar cell at a high temperature to activate the dopants and bond the metal contacts.

2. What are the different types of crystalline silicon solar cells and how do they differ in terms of efficiency and cost?

Monocrystalline Silicon Solar Cells

- Highest efficiency (up to 26%)

- Single-crystal silicon structure

- Highest cost per watt

Polycrystalline Silicon Solar Cells

- Lower efficiency (up to 22%)

- Multiple-crystal silicon structure

- Lower cost per watt than monocrystalline cells

Amorphous Silicon Solar Cells

- Lowest efficiency (up to 15%)

- Non-crystalline silicon structure

- Lowest cost per watt

3. Explain the concept of the p-n junction in a solar cell. How does it contribute to the generation of electricity?

A p-n junction is a semiconductor junction formed by joining a p-type semiconductor (with a majority of holes) and an n-type semiconductor (with a majority of electrons). In a solar cell, the p-n junction is created by doping one side of the silicon wafer with phosphorus (n-type) and the other side with boron (p-type).

When sunlight strikes the solar cell, it generates electron-hole pairs in the silicon material. These electron-hole pairs are separated by the p-n junction: electrons are pushed to the n-type side, while holes are pushed to the p-type side. This separation of charges creates an electric field across the p-n junction, which drives the electrons through an external circuit, generating electricity.

4. What are the factors that affect the efficiency of a solar cell?

- Bandgap: The energy difference between the valence band and the conduction band in the semiconductor material.

- Optical losses: Light reflection, absorption, and scattering in the solar cell materials.

- Recombination losses: Loss of electron-hole pairs due to recombination before they can be separated and collected.

- Electrical losses: Resistance in the semiconductor material and metal contacts.

- Temperature effects: Efficiency decreases as temperature increases.

5. Describe the role of anti-reflection coatings in enhancing the efficiency of solar cells.

Anti-reflection coatings are thin layers of materials deposited on the surface of a solar cell to minimize light reflection and increase light absorption. They are typically made of materials with a low refractive index, such as silicon nitride or titanium dioxide.

Anti-reflection coatings work by reducing the reflection coefficient of the solar cell surface, which allows more light to enter the semiconductor material and generate electron-hole pairs. This increased light absorption leads to higher solar cell efficiency.

6. Explain the concept of maximum power point tracking (MPPT) in solar energy systems.

Maximum power point tracking (MPPT) is a technique used in solar energy systems to maximize the amount of power generated by the solar panels. It involves tracking the maximum power point (MPP) of the solar array and adjusting the load or system parameters to operate at that point.

MPPT algorithms monitor the voltage and current output of the solar array and calculate the MPP using various methods, such as the perturb and observe method or the incremental conductance method. The algorithm then adjusts the load or system parameters, such as the duty cycle of a DC-DC converter or the angle of a solar tracker, to operate at the MPP.

7. Discuss the challenges and opportunities in the field of solar process engineering.

Challenges:

- Continuous improvement of solar cell efficiency

- Reducing manufacturing costs to make solar energy more affordable

- Developing new and innovative solar cell technologies

- Addressing environmental concerns related to solar cell manufacturing

Opportunities:

- Growing demand for renewable energy sources

- Technological advancements in solar cell materials and processes

- Government incentives and policies supporting solar energy

- Potential for large-scale solar energy deployment

8. How do you stay up-to-date with the latest advancements in solar process engineering?

- Attending industry conferences and workshops

- Reading technical journals and whitepapers

- Networking with other solar professionals

- Following industry news and developments online

- Participating in research and development projects

9. Describe a project or experience where you applied your knowledge of solar process engineering to solve a problem or improve a process.

In my previous role as a solar process engineer, I worked on a project to improve the efficiency of a solar cell fabrication process. I analyzed the existing process, identified areas for improvement, and implemented new process parameters. Through careful experimentation and optimization, I was able to increase the efficiency of the solar cells by 2%.

10. What are your career goals and how do you see this role fitting into your long-term aspirations?

My long-term career goal is to become a leading solar process engineer and contribute to the advancement of solar energy technology. I believe that this role will provide me with the necessary experience and opportunities to develop my skills and knowledge in the field. I am eager to work on challenging projects and contribute to the company’s mission of providing affordable and sustainable solar energy solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Solar Process Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Solar Process Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Solar Process Engineer is responsible for the development, implementation, and optimization of processes for the manufacture of solar cells and modules. They work closely with other engineers, scientists, and technicians to ensure that the production process is efficient and effective, and that the products meet the required specifications.

1. Process Development

Develop and improve processes for the fabrication of solar cells and modules.

- Investigate new materials and technologies.

- Design and build prototype equipment.

2. Process Implementation

Implement new processes in the production environment.

- Train operators on new procedures.

- Troubleshoot and resolve production issues.

3. Process Optimization

Monitor and analyze production data to identify areas for improvement.

- Develop and implement process changes to improve yields and reduce costs.

- Work with suppliers to improve the quality of materials.

4. Quality Control

Ensure that the finished products meet the required specifications.

- Conduct quality inspections.

- Identify and resolve quality issues.

Interview Tips

Preparing for a job interview can be nerve-wracking, but it’s also an opportunity to showcase your skills and experience. Here are a few tips to help you ace your interview for a Solar Process Engineer position:

1. Research the Company

Take the time to learn about the company’s history, mission, and products. This will help you understand their business and the role that the Solar Process Engineer plays within the organization.

- Visit the company’s website.

- Read articles and press releases about the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Quantify your accomplishments whenever possible.

3. Be Prepared to Talk About Your Experience

The interviewer will likely want to know about your experience in solar process engineering. Be prepared to discuss your skills and experience in detail, and provide examples of your work.

- Highlight your experience in process development, implementation, and optimization.

- Discuss your experience with different solar cell and module technologies.

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the role and the organization.

- Ask about the company’s growth plans.

- Ask about the challenges that the company is facing.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Solar Process Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.