Feeling lost in a sea of interview questions? Landed that dream interview for Solder Making Laborer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Solder Making Laborer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

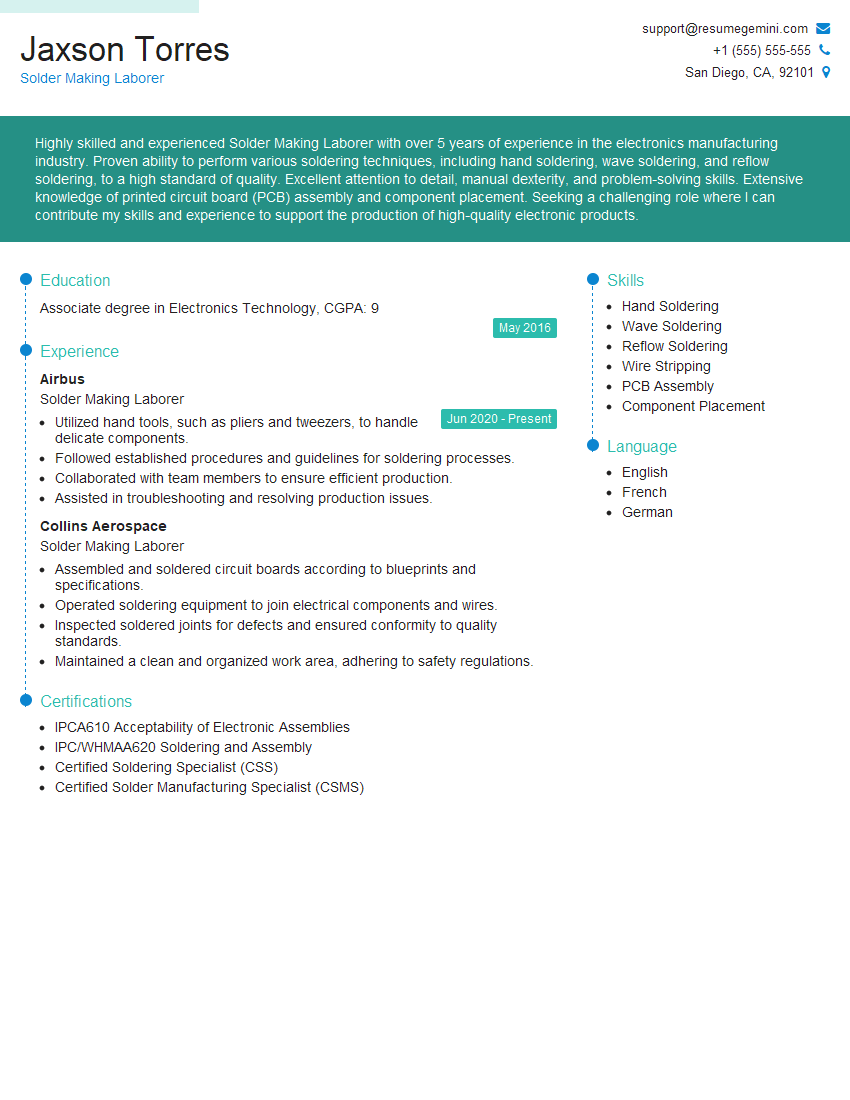

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Solder Making Laborer

1. What are the different types of solder joints you are familiar with?

I have worked with various types of solder joints, including:

- Lap joint: This is a simple joint used when the two pieces of metal overlap.

- Butt joint: This joint is used when two pieces of metal are placed end-to-end.

- Edge joint: This joint is used when two pieces of metal are joined at their edges.

- T-joint: This joint is used when one piece of metal is perpendicular to another.

- Mitre joint: This joint is used when two pieces of metal are cut at an angle and joined together to form a corner.

2. What are the essential steps in preparing for soldering?

Surface cleaning

- Remove any dirt, oil or corrosion from the surfaces to be joined.

- This can be done by using a wire brush, sandpaper, or a chemical cleaner.

Flux application

- Apply a flux to the surfaces to be joined.

- Flux helps the solder to flow smoothly over the surfaces

Proper heating

- Heat the surfaces to be joined to the appropriate temperature.

- The temperature should be high enough to melt the solder but not so high as to damage the components.

3. Can you describe the process of wave soldering?

In wave soldering, a pump creates a wave of molten solder that passes over the printed circuit board (PCB).

- The PCB is passed through the wave, and the solder wets the exposed metal surfaces.

- This creates a strong and reliable connection between the components and the PCB.

- Wave soldering is a widely used method for soldering components to PCBs because it is efficient and produces consistent results.

4. What is the purpose of solderability testing?

Solderability testing is performed to evaluate the ability of a material to be soldered.

- This is important because solderability affects the quality and reliability of soldered joints.

- Solderability testing can be performed using a variety of methods, such as the wetting balance test or the solderability dip test.

5. Explain the difference between hard solder and soft solder.

- Hard solder: It has a higher melting point than soft solder and is typically used for stronger joints that require higher temperatures.

- Soft solder: It melts at a lower temperature and is commonly used for delicate components or in applications where a strong joint is not required.

6. What are the safety precautions that should be observed when soldering?

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator.

- Ensure that the work area is well-ventilated to avoid inhaling harmful fumes.

- Never touch the tip of the soldering iron or the molten solder.

- Always use a soldering stand to hold the soldering iron when not in use.

- Never leave the soldering iron unattended.

7. What are the different types of solder fluxes available?

- Rosin: This is the most common type of flux and is made from pine tree sap.

- Acid flux: This is a stronger flux that is used for soldering metals that are difficult to solder.

- No-clean flux: This is a flux that does not leave any residue after soldering.

8. What is the function of a soldering iron tip?

The soldering iron tip is the part of the soldering iron that comes into contact with the solder and the workpieces.

- It is typically made of copper and is coated with a layer of solder to prevent oxidation.

- The tip transfers heat from the soldering iron to the solder and the workpieces, allowing the solder to melt and flow.

9. What are the common defects that can occur in soldered joints?

- Cold solder joint: This occurs when the solder does not melt properly and forms a weak joint.

- Bridging: This occurs when solder flows between two or more conductors, creating a short circuit.

- Solder ball: This occurs when a small ball of solder forms on the surface of the joint.

- Solder icicle: This occurs when a long, thin strand of solder forms on the surface of the joint.

10. What is the best way to remove solder from a circuit board?

- Solder wick: This is a braided copper wire that is used to absorb molten solder.

- Solder sucker: This is a vacuum-operated device that is used to remove solder from a circuit board.

- Hot air gun: This can be used to melt the solder and remove it from the circuit board.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Solder Making Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Solder Making Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Solder Making Laborers are responsible for various tasks related to the production of solder, an alloy used in electronic assembly and other applications. Their key job responsibilities include:

1. Materials Handling

Moving and handling raw materials, such as metal ingots, fluxes, and solvents, safely and efficiently

- Loading and unloading materials onto and from conveyors, forklifts, and other equipment

- Ensuring proper storage of materials to prevent contamination and maintain quality

2. Equipment Operation

Operating and monitoring solder-making equipment, including furnaces, casting machines, and extruders

- Setting up and adjusting equipment parameters according to established procedures

- Maintaining and troubleshooting equipment to ensure smooth production

3. Process Monitoring

Monitoring the solder-making process to ensure compliance with quality standards

- Sampling and testing solder to verify its composition and properties

- Adjusting process parameters based on test results to optimize solder quality

4. Maintenance and Cleaning

Performing regular maintenance and cleaning tasks on equipment and work areas

- Lubricating and cleaning moving parts to prevent wear and tear

- Maintaining a clean and organized work environment to prevent contamination

Interview Tips

To ace an interview for a Solder Making Laborer position, candidates should take the following preparation tips into consideration:

1. Research the Company and Position

Thoroughly research the company and the specific Solder Making Laborer role. Learn about the company’s products, services, and industry standing. This knowledge will demonstrate your interest and preparedness during the interview.

- Visit the company’s website and social media pages

- Review job descriptions and industry articles to gain insights into the role

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Anticipating these questions will help you deliver clear and concise answers.

- “Tell me about your experience in solder making or related roles.”

- “Describe your knowledge of solder metallurgy and its applications.”

- “How do you ensure the quality and consistency of the solder you produce?”

3. Highlight Safety and Attention to Detail

Emphasize your commitment to safety and attention to detail. Solder Making Laborers are responsible for handling hazardous materials and operating heavy equipment. Showcase your understanding of safety protocols and your meticulous approach to work.

- Describe your experience with workplace safety regulations and practices

- Provide examples of how you ensure accuracy and precision in your tasks

4. Show Your Physical Abilities and Endurance

Solder Making Laborers often perform physically demanding tasks. During the interview, convey your physical abilities, endurance, and willingness to work in a fast-paced environment.

- Mention your ability to lift heavy objects and work for extended periods

- Discuss your experience working in a physically demanding environment

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for the interview and arrive on time. This demonstrates your respect for the interviewer and your commitment to the position.

- Choose business attire or work-appropriate clothing

- Plan your commute in advance to avoid any delays

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Solder Making Laborer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!