Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Solderer-Dipper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Solderer-Dipper so you can tailor your answers to impress potential employers.

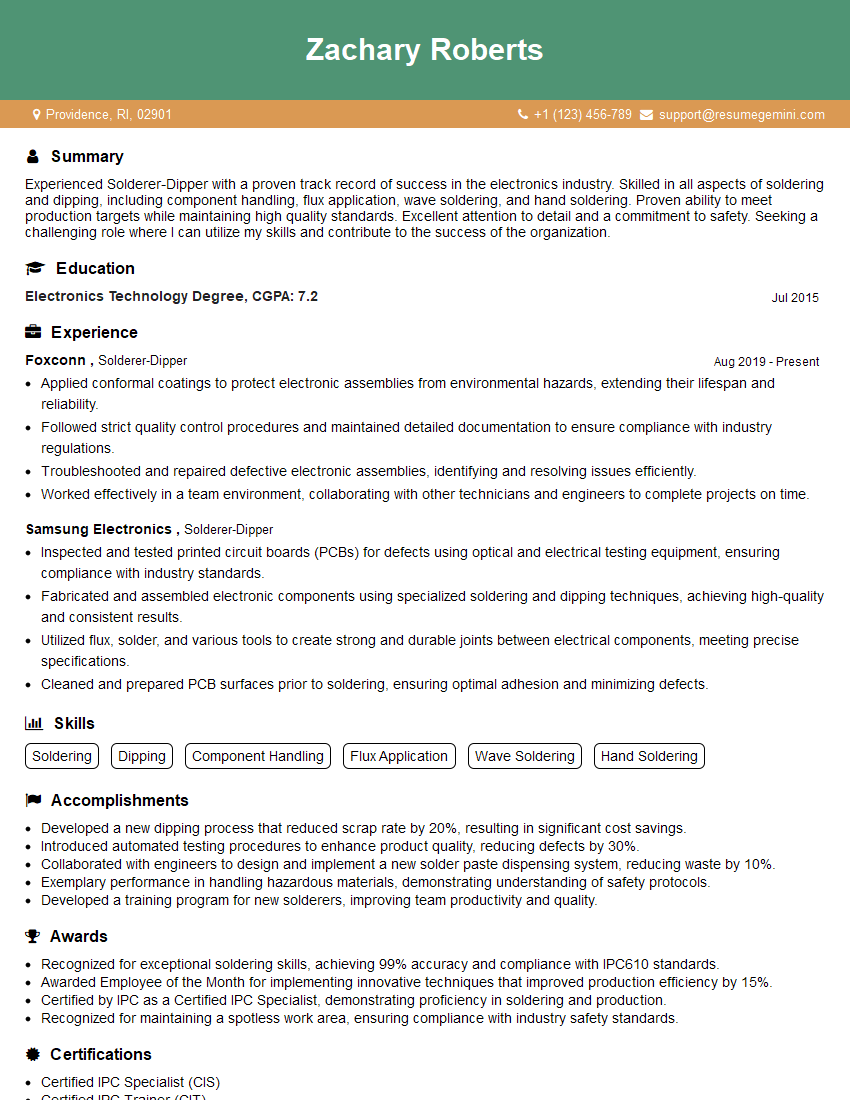

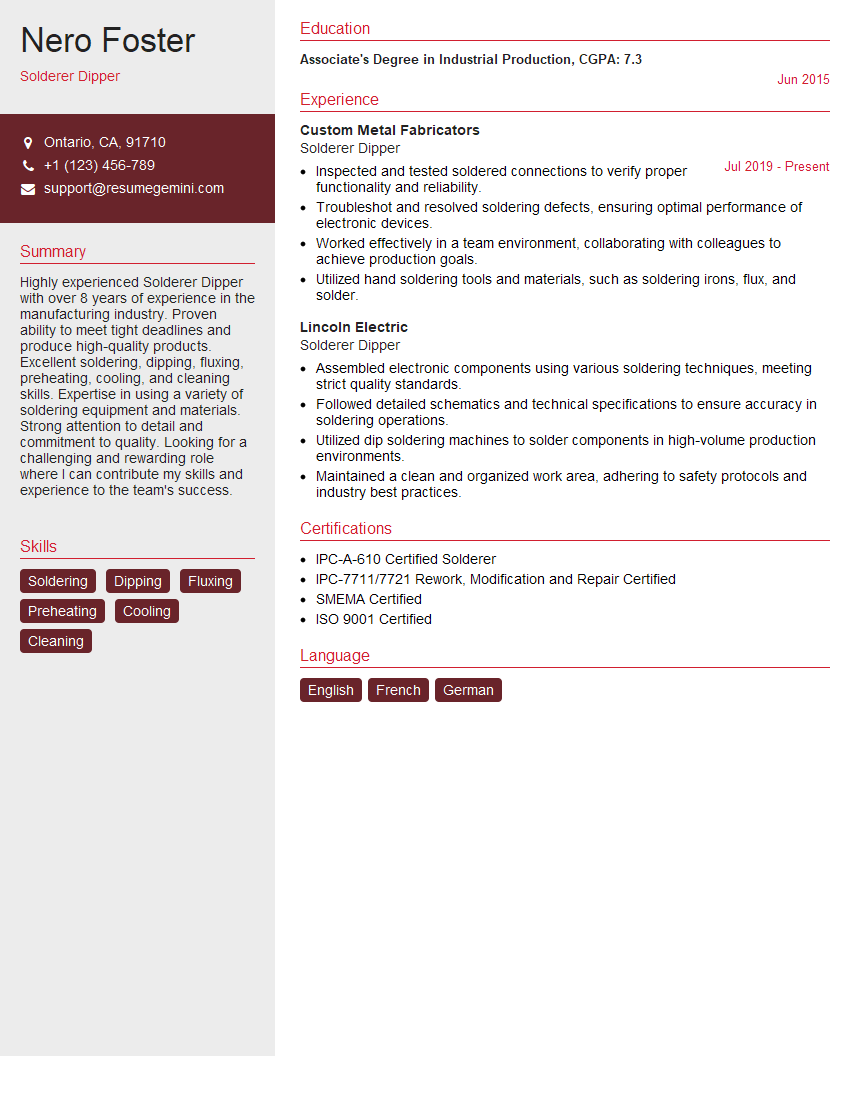

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Solderer-Dipper

1. What types of soldering techniques are you familiar with?

In my experience, I have become proficient in several soldering techniques, including:

- Hand soldering

- Wave soldering

- Reflow soldering

2. How do you ensure the quality of your soldering work?

Visual Inspection

- Inspecting solder joints for proper shape, size, and appearance

- Verifying that components are securely attached and correctly positioned

Electrical Testing

- Conducting continuity tests to ensure electrical connectivity

- Performing insulation resistance tests to check for any electrical leakage

3. What is the importance of using proper soldering materials?

- Ensuring optimal electrical conductivity and mechanical strength

- Preventing cold solder joints, which can lead to poor connectivity and reliability

- Minimizing the risk of solder bridges and shorts, which can cause circuit malfunctions

4. Can you describe the different types of solder fluxes and their applications?

- Rosin-based fluxes: Commonly used for electronic assembly, providing good wetting and low residue

- Water-soluble fluxes: Leave no residue, making them ideal for applications where cleanliness is critical

- Acid-based fluxes: Highly active and effective for removing oxides, but can be corrosive and require careful cleaning

5. How do you handle rework and repair of soldered joints?

- Using desoldering tools and techniques to remove old solder

- Cleaning the contact surfaces and applying new solder

- Inspecting the repaired joint to ensure proper connectivity and appearance

6. What safety precautions should be taken when soldering?

- Using appropriate ventilation to avoid inhaling soldering fumes

- Wearing protective gear, such as safety glasses and gloves

- Handling heated soldering irons and molten solder with care to prevent burns

7. What are the common defects that can occur in soldering and how do you prevent them?

- Cold solder joints: Caused by insufficient heat or improper wetting, can be prevented by using the correct soldering technique and solder materials

- Solder bridges: Occur when excess solder flows between adjacent conductors, can be avoided by using proper solder quantity and avoiding bridging

- Solder balls: Result from splattered or oxidized solder, can be minimized by using clean solder and controlling the soldering temperature

8. What is the role of solderability testing in quality control?

- Assessing the ability of a surface to be wetted by solder

- Identifying potential soldering problems before production

- Verifying the effectiveness of cleaning processes and solderability treatments

9. How do you stay updated with the latest techniques and developments in the soldering field?

- Attending industry workshops and seminars

- Reading technical publications and online resources

- Networking with other soldering professionals and sharing best practices

10. Can you troubleshoot common soldering equipment issues, such as solder iron problems or malfunctioning soldering machines?

- Solder iron issues: Identifying faulty heating elements, loose connections, or clogged tips

- Soldering machine problems: Troubleshooting conveyor malfunctions, temperature control failures, or solder feeding issues

- Proper maintenance and calibration: Ensuring equipment is regularly serviced and calibrated to maintain performance and accuracy

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Solderer-Dipper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Solderer-Dipper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Solderers-Dippers are responsible for soldering and dipping components and assemblies in a manufacturing environment. Their primary duties involve:

1. Soldering

Using soldering irons, torches, or other equipment, solderers-dippers join electrical components and wires by melting solder and applying it to the connection points.

- Follows established soldering procedures and standards.

- Inspects soldered joints for quality and conformance to specifications.

2. Dipping

They immerse components and assemblies in molten solder or other chemical solutions to coat or seal them.

- Prepares components and assemblies for dipping.

- Controls the temperature and timing of the dipping process.

3. Quality Control and Inspection

Solderers-dippers inspect their work and ensure that the soldered joints and dipped components meet quality standards.

- Conducts visual and physical inspections of soldered joints and dipped components.

- Uses testing equipment to verify the electrical continuity and functionality of soldered connections.

4. Equipment Maintenance

They perform basic maintenance and cleaning of soldering equipment.

- Cleans and maintains soldering irons, torches, and dipping tanks.

- Reports any equipment malfunctions or issues to supervisors.

Interview Tips

To ace an interview for a Solderer-Dipper position, candidates should prepare thoroughly and showcase their skills and experience. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Research the specific job requirements and understand the key responsibilities of a Solderer-Dipper.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Highlight Relevant Skills and Experience

Emphasize your soldering and dipping skills, as well as your experience in manufacturing or a related field. Quantify your accomplishments whenever possible.

- Describe the soldering and dipping techniques you have mastered.

- Provide examples of projects where you successfully soldered and dipped components.

3. Showcase Quality Control and Inspection Expertise

Demonstrate your understanding of quality control standards and your ability to inspect soldered joints and dipped components.

- Explain the quality control procedures you have followed.

- Describe the testing equipment you have used and how you have interpreted test results.

4. Prepare for Technical Questions

Be prepared to answer questions about soldering techniques, dipping processes, and quality control methods. Review the basics of electrical connections and soldering materials.

- Study different types of solder and their applications.

- Practice soldering and dipping techniques on scrap materials.

5. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about your experience,” “Why are you interested in this position,” and “What are your strengths and weaknesses.” Practice answering these questions concisely and professionally.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Seek feedback from a friend, family member, or career counselor on your interview skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Solderer-Dipper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.