Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Soldering Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

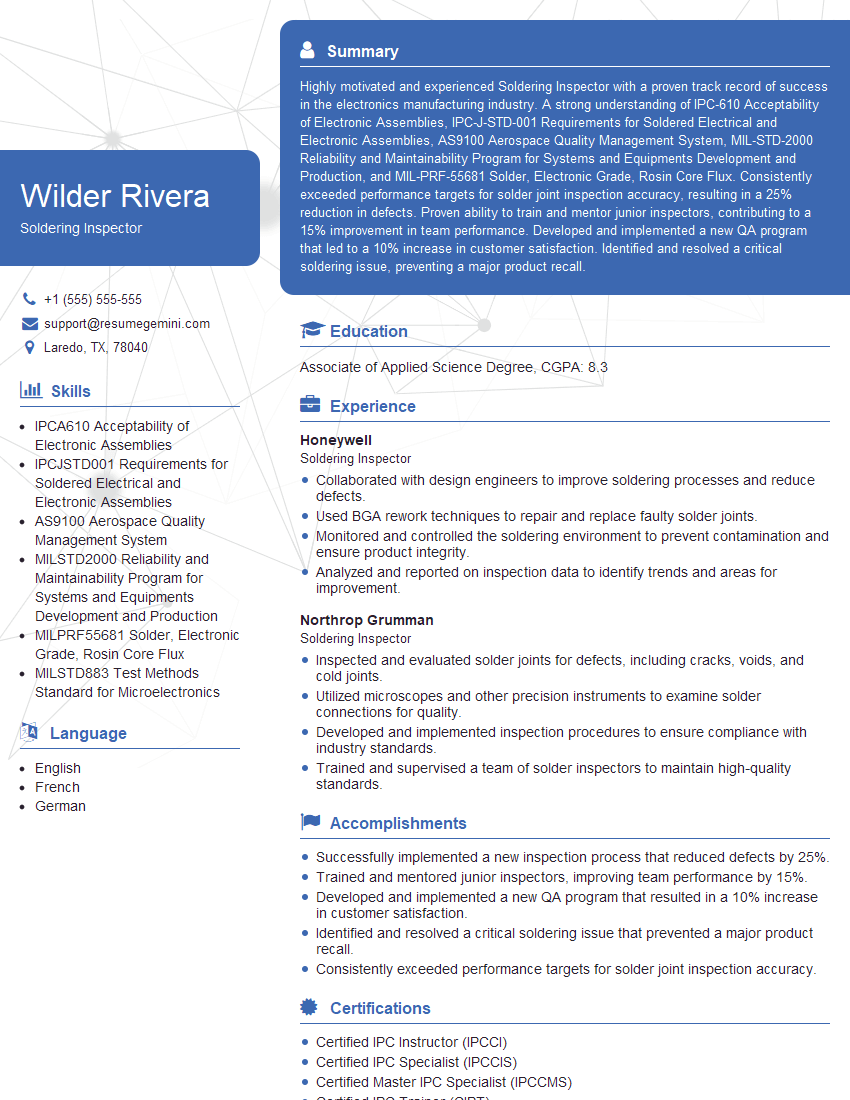

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Soldering Inspector

1. What are the different types of solder joints and how do you inspect them?

There are several types of solder joints, including:

- Through-hole solder joints

- Surface-mount solder joints

- Wire-wrap solder joints

- Crimp solder joints

To inspect solder joints, I use a variety of techniques, including:

- Visual inspection

- Microscopic inspection

- X-ray inspection

- Electrical testing

2. What are the most common defects in solder joints and how do you identify them?

Visual Inspection

- Solder bridges

- Cold solder joints

- Insufficient solder

- Excessive solder

- Solder voids

Microscopic Inspection

- Intermetallic compounds

- Cracks

- Delamination

- Corrosion

- Pitting

3. What are the different types of soldering equipment and how do you use them?

The most common types of soldering equipment include:

- Soldering irons

- Soldering guns

- Soldering stations

- Wave soldering machines

- Reflow ovens

I am familiar with all of these types of equipment and can use them to solder a variety of materials.

4. What is the difference between lead-based and lead-free solder?

- Lead-based solder is a type of solder that contains lead. It is a eutectic alloy, which means that it has a single melting point. Lead-based solder is relatively easy to use and it produces strong, reliable solder joints.

- Lead-free solder is a type of solder that does not contain lead. It is typically made from a combination of tin, silver, and copper. Lead-free solder is more difficult to use than lead-based solder, but it is also more environmentally friendly.

5. What are the safety precautions that you take when soldering?

- Wear appropriate safety gear, including eye protection, gloves, and a lab coat.

- Use a well-ventilated area.

- Keep the soldering iron away from flammable materials.

- Do not touch the hot soldering iron with your bare hands.

- Allow the soldering iron to cool before storing it.

6. What are the different types of flux and how do you use them?

- Rosin flux is a type of flux that is made from the resin of pine trees. It is the most common type of flux and it is used for soldering a variety of metals.

- Acid flux is a type of flux that is made from hydrochloric acid or sulfuric acid. It is more aggressive than rosin flux and it is used for soldering metals that are difficult to solder, such as aluminum and stainless steel.

- No-clean flux is a type of flux that does not leave a residue after soldering. It is ideal for use in applications where cleanliness is important, such as in the assembly of electronic devices.

7. What are the different types of solder masks and how do you apply them?

- Liquid solder mask is a type of solder mask that is applied in liquid form. It is then cured by exposure to heat or ultraviolet light.

- Dry film solder mask is a type of solder mask that is applied in film form. It is then laminated to the printed circuit board.

- Photoimageable solder mask is a type of solder mask that is applied in liquid form. It is then exposed to ultraviolet light through a photomask, which creates the desired solder mask pattern.

8. What are the different types of solder preforms and how do you use them?

- Solder preforms are pre-shaped pieces of solder that are used to simplify the soldering process. They are available in a variety of shapes and sizes.

- Solder balls are round solder preforms that are used for soldering small components, such as surface-mount devices.

- Solder rings are ring-shaped solder preforms that are used for soldering wires and other cylindrical objects.

- Solder washers are washer-shaped solder preforms that are used for soldering nuts and bolts.

9. What are the different types of soldering defects and how do you prevent them?

- Solder bridges are solder connections that form between two or more conductors that are not supposed to be connected.

- Cold solder joints are solder joints that are not properly melted and fused together.

- Insufficient solder is a condition in which there is not enough solder to create a strong and reliable solder joint.

- Excessive solder is a condition in which there is too much solder, which can create a weak and unreliable solder joint.

- Solder voids are empty spaces within a solder joint.

10. What is the importance of quality control in soldering?

Quality control is essential in soldering to ensure that the solder joints are strong, reliable, and meet the required specifications. Poor quality solder joints can lead to a variety of problems, including electrical failures, shorts, and opens. I am committed to maintaining a high level of quality control in my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Soldering Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Soldering Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Soldering Inspectors are responsible for ensuring that soldered joints meet the required quality standards. They visually inspect joints to identify any defects, such as voids, cracks, or misalignments. They also use specialized equipment to test the strength and reliability of joints. Additionally, they may be responsible for developing and implementing quality control procedures, training other inspectors, and maintaining inspection records.

1. Inspect soldered joints for defects

Soldering Inspectors use various techniques to inspect soldered joints, including visual inspection, microscopy, and X-ray. They look for defects such as voids, cracks, misalignments, and other irregularities. They also check for compliance with specifications and standards.

2. Test the strength and reliability of joints

Soldering Inspectors use specialized equipment, such as tensile testers and shear testers, to test the strength and reliability of soldered joints. They apply force to the joints to determine their breaking point and measure their resistance to deformation.

3. Develop and implement quality control procedures

Soldering Inspectors may be responsible for developing and implementing quality control procedures to ensure that soldered joints meet the required standards. They establish inspection criteria, define acceptable defect levels, and implement corrective actions when defects are found.

4. Train other inspectors

Soldering Inspectors may be responsible for training other inspectors on inspection techniques, quality control procedures, and the use of specialized equipment. They provide guidance and support to ensure that all inspectors are qualified and competent.

5. Maintain inspection records

Soldering Inspectors maintain inspection records, including the results of inspections, any defects found, and corrective actions taken. They use this information to track trends, identify areas for improvement, and demonstrate compliance with quality standards.

Interview Tips

To help candidates ace their interview for a Soldering Inspector position, here are some tips:

1. Research the company and the position

Before the interview, take the time to research the company and the specific Soldering Inspector position you are applying for. Learn about the company’s products, services, and industry. Understand the key responsibilities and qualifications for the position. This preparation will help you demonstrate your interest in the company and the role, and it will give you a better understanding of the expectations.

2. Practice your answers to common interview questions

Anticipate common interview questions and prepare your answers in advance. Practice articulating your skills, experience, and qualifications in a clear and concise manner. Consider using the STAR method to structure your answers: Situation, Task, Action, Result. This method allows you to provide specific examples of your accomplishments and demonstrate how you can add value to the company.

3. Highlight your technical skills and experience

Soldering Inspectors are expected to have a solid understanding of soldering techniques, quality control procedures, and the use of specialized equipment. In your interview, emphasize your technical skills and experience in these areas. Provide examples of projects or situations where you have successfully identified and resolved soldering defects. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

4. Demonstrate your attention to detail and commitment to quality

Soldering Inspectors must have a keen eye for detail and a commitment to maintaining high quality standards. In the interview, highlight your ability to identify even the smallest defects and your dedication to ensuring that all soldered joints meet specifications. Share examples of your involvement in quality improvement initiatives or your contributions to the development of quality control procedures.

5. Ask thoughtful questions

At the end of the interview, take the opportunity to ask thoughtful questions about the company, the position, and the industry. This shows that you are engaged and interested in the role. It also gives you a chance to gather additional information that can help you make an informed decision about whether the position is the right fit for you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Soldering Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!