Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Soldering Machine Setter and Setup Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

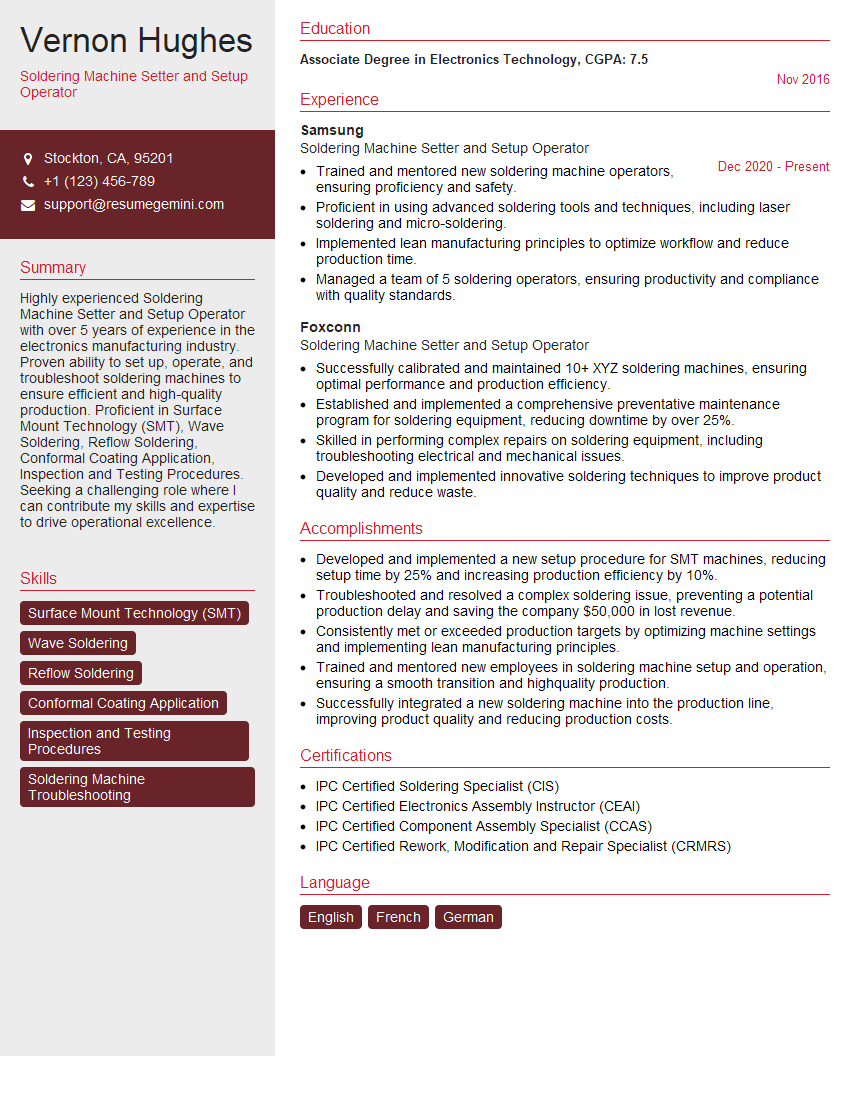

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Soldering Machine Setter and Setup Operator

1. Describe the process of setting up a soldering machine?

- Inspect the machine to ensure it is in good working condition.

- Install the appropriate tips and nozzles.

- Calibrate the machine according to the manufacturer’s specifications.

- Program the machine with the soldering parameters.

- Load the solder and flux onto the machine.

- Test the machine to ensure it is functioning properly.

2. What are the different types of soldering machines?

Wave soldering machines

- Used for high-volume soldering of printed circuit boards (PCBs).

- Solder is melted in a wave and pumped onto the PCB.

Reflow soldering machines

- Used for high-volume soldering of surface-mount components (SMCs).

- Solder paste is applied to the PCB and then heated to reflow the solder.

Selective soldering machines

- Used for precision soldering of individual components.

- A soldering iron is used to apply solder to specific points on the PCB.

3. What are the most common problems that you encounter when operating a soldering machine?

- Solder bridging: Occurs when solder flows between two or more components.

- Solder voids: Occurs when there is not enough solder between two components.

- Tombstoning: Occurs when a component is lifted off the PCB during soldering.

- Headaches: Occurs when solder fumes are inhaled.

- Eye strain: Occurs when looking at the soldering machine for long periods of time.

4. How do you troubleshoot a soldering machine?

- Check the power supply to the machine.

- Check the solder and flux levels.

- Check the calibration of the machine.

- Check the soldering tips and nozzles for wear.

- Check the program settings on the machine.

5. What are the safety precautions that you must take when operating a soldering machine?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a lab coat.

- Operate the machine in a well-ventilated area.

- Do not smoke or eat while operating the machine.

- Keep the work area clean and free of clutter.

- Be aware of the potential hazards of solder fumes and take steps to minimize exposure.

6. What is the difference between solder and flux?

- Solder is a metal alloy that is used to join two pieces of metal together.

- Flux is a chemical that is used to remove oxides from the metal surfaces and to promote the flow of solder.

7. What are the different types of solder?

- Lead-based solder: Contains lead and tin.

- Lead-free solder: Does not contain lead.

- Solid solder: Is in the form of a solid wire.

- Paste solder: Is in the form of a paste.

8. What are the different types of flux?

- Rosin-based flux: Contains rosin and is used for general-purpose soldering.

- Water-soluble flux: Can be removed with water and is used for soldering delicate components.

- No-clean flux: Does not need to be removed after soldering.

9. What are the different methods of soldering?

- Hand soldering: Uses a soldering iron to apply solder to the components.

- Wave soldering: Uses a wave of solder to solder the components.

- Reflow soldering: Uses a heat source to reflow the solder.

- Selective soldering: Uses a soldering iron to solder specific points on the PCB.

10. What are the quality standards for soldering?

- IPC-A-610: Standard for Acceptability of Electronic Assemblies.

- MIL-STD-2000: Standard for Soldering of Electrical and Electronic Assemblies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Soldering Machine Setter and Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Soldering Machine Setter and Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Soldering Machine Setter and Setup Operator is a crucial role in the manufacturing process, responsible for ensuring the efficient and accurate operation of soldering machines.

1. Machine Setup and Maintenance

Sets up and adjusts soldering machines according to specifications and work orders.

- Calibrates and tests machines to ensure proper functioning and accuracy.

- Performs routine maintenance tasks such as cleaning, lubricating, and replacing parts.

2. Process Optimization

Develops and implements soldering processes to improve efficiency and quality.

- Selects and sets appropriate soldering parameters, materials, and equipment.

- Troubleshoots and resolves soldering issues to minimize downtime.

3. Quality Assurance

Verifies the quality of soldered joints to meet customer specifications.

- Inspects soldered products visually and through non-destructive testing methods.

- Keeps records of inspection results and implements corrective actions to improve quality.

4. Production Monitoring

Monitors soldering machine performance and productivity.

- Tracks production output, downtime, and quality metrics.

- Identifies areas for improvement and makes recommendations to optimize production.

Interview Tips

Preparing for a job interview as a Soldering Machine Setter and Setup Operator requires thorough research and practice.

1. Research the Company and Industry

Gather information about the company, its products, and the soldering industry as a whole.

- Visit the company website and read industry publications.

- Identify any recent developments or trends in soldering technology.

2. Practice Your Responses

Prepare answers to common interview questions, focusing on your skills and experience.

- Highlight your expertise in soldering machine setup, process optimization, and quality assurance.

- Provide specific examples of how you have improved efficiency or reduced downtime.

3. Demonstrate Your Technical Knowledge

In addition to soft skills, employers will be interested in your technical abilities.

- Be prepared to discuss soldering techniques, materials, and equipment.

- Explain how you approach troubleshooting and resolving soldering issues.

4. Emphasize Safety and Compliance

Safety is paramount in the manufacturing industry.

- Highlight your knowledge of safety regulations and best practices.

- Explain how you ensure compliance with environmental and health standards.

Next Step:

Now that you’re armed with the knowledge of Soldering Machine Setter and Setup Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Soldering Machine Setter and Setup Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini