Are you gearing up for an interview for a Soldering Machine Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Soldering Machine Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

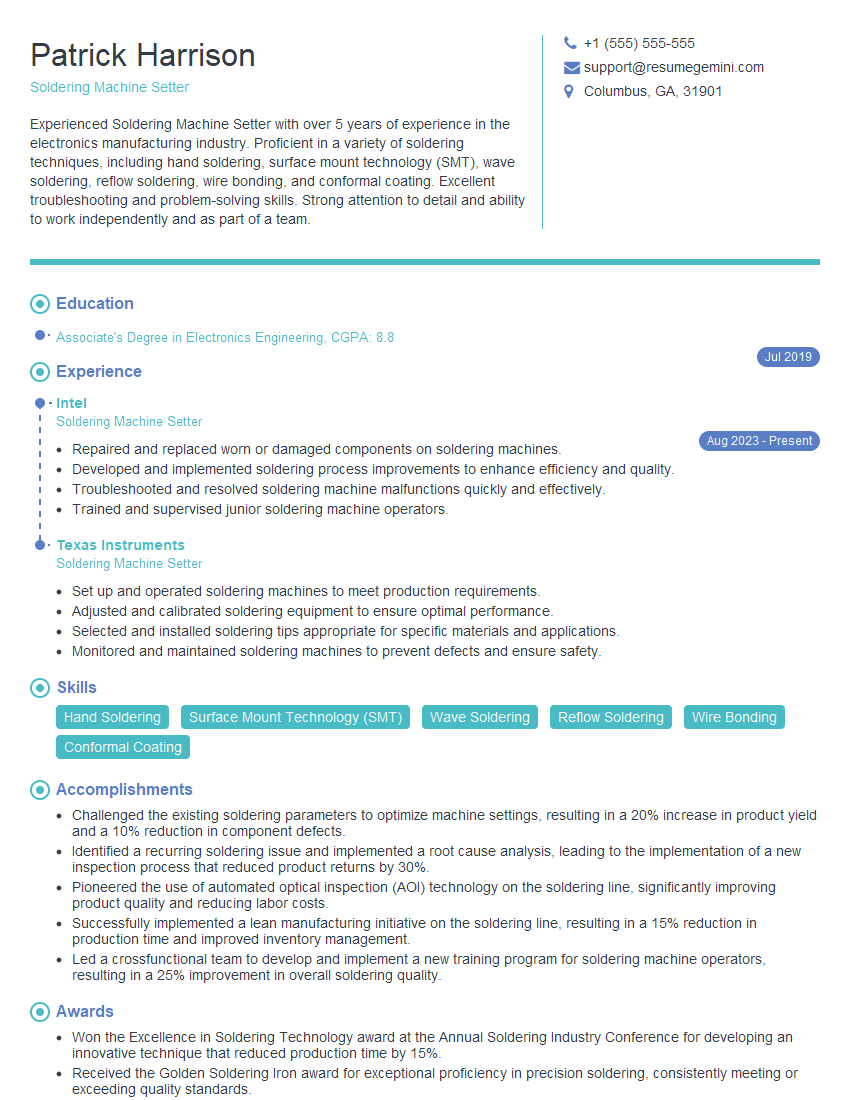

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Soldering Machine Setter

1. Describe the process of setting up a soldering machine.

The process of setting up a soldering machine involves several key steps:

- Preparation: Gather necessary materials, including solder, flux, and cleaning agents.

- Machine Inspection: Check the machine for any damage or malfunctions.

- Soldering Iron Calibration: Set the temperature and adjust the tip to suit the specific soldering requirements.

- Material Loading: Load the solder wire and flux into their designated compartments.

- Program Configuration: Input the soldering parameters, such as temperature, speed, and dwell time, based on the product specifications.

- Test Soldering: Perform a test soldering to ensure proper operation and adjust settings as needed.

- Safety Precautions: Verify that all safety measures are in place, including proper ventilation and eye protection.

2. How do you troubleshoot common soldering problems?

Identifying Root Causes

- Cold solder joints: Insufficient heat or solder application.

- Bridging: Excess solder connecting adjacent solder points.

- Solder balls: Small globules of solder forming on the board.

- Tombstoning: Components leaning excessively due to uneven solder application.

Troubleshooting Strategies

- Adjusting temperature and dwell time.

- Inspecting and cleaning soldering iron tip.

- Verifying solder composition and flux compatibility.

- Optimizing component placement and solder application.

- Reviewing and revising soldering procedures to prevent defects.

3. What maintenance tasks are required for soldering machines?

- Regular Cleaning: Remove solder residue, flux, and contaminants from the tip, board, and machine.

- Tip Maintenance: Inspect and replace soldering iron tips as needed to maintain optimal heat transfer.

- Calibration: Ensure accurate temperature and other parameters by performing periodic calibration checks.

- Lubrication: Apply lubricant to moving parts to prevent wear and tear.

- Software Updates: Install software updates to enhance functionality and address any performance issues.

4. Explain the different types of soldering techniques and their applications.

- Hand Soldering: Manual soldering using a soldering iron, suitable for small-scale or intricate work.

- Wave Soldering: A mass production technique where a wave of molten solder flows over a circuit board, ideal for high-volume applications.

- Reflow Soldering: A solder paste is applied to the board, and then heat is applied to melt the solder, suitable for surface-mount components.

- Laser Soldering: A focused laser beam is used to melt solder, providing precise control and minimal thermal impact.

5. How do you ensure the quality of soldered joints?

- Visual Inspection: Examine solder joints for proper shape, wetting, and absence of defects.

- Mechanical Testing: Conduct pull tests or shear tests to verify joint strength.

- Electrical Testing: Perform continuity checks and other electrical tests to ensure functionality.

- Adherence to Standards: Comply with industry standards and specifications for soldering quality.

- Continuous Improvement: Regularly review and optimize soldering processes to enhance quality and efficiency.

6. Describe the safety precautions to be taken when operating soldering machines.

- Eye Protection: Wear safety glasses or goggles to protect eyes from molten solder and fumes.

- Ventilation: Ensure proper ventilation to prevent inhalation of harmful fumes.

- Hot Surfaces: Handle soldering irons and equipment with care to avoid burns.

- Electrical Safety: Ground the soldering machine and handle electrical connections safely.

- Fire Prevention: Keep the work area free from flammable materials and have a fire extinguisher nearby.

7. Explain the importance of using the correct solder and flux for different applications.

- Solder Composition: Selecting the appropriate solder alloy (e.g., tin-lead, lead-free) based on compatibility with components and board materials.

- Flux Type: Choosing the right flux (e.g., rosin, acid-based) to remove oxides and promote wetting of solder to surfaces.

- Matching Solder and Flux: Ensuring compatibility between the solder and flux to optimize joint quality and performance.

8. How do you optimize soldering parameters to achieve reliable solder joints?

- Temperature Control: Setting the appropriate soldering iron temperature based on solder and component characteristics.

- Dwell Time: Adjusting the time the soldering iron stays in contact with the joint to ensure proper heat transfer.

- Solder Amount: Applying the optimal amount of solder to create strong and durable joints.

- Soldering Speed: Maintaining a consistent soldering speed to prevent overheating or insufficient heat.

9. Discuss the challenges faced in soldering miniaturized components and how to overcome them.

- Precision Soldering: Utilizing specialized tools and techniques to ensure accurate and precise soldering on small components.

- Heat Control: Managing heat effectively to prevent damage to delicate components.

- Flux Selection: Choosing low-residue fluxes to avoid contamination and potential short circuits.

- Equipment Optimization: Using microscopes or magnification systems for better visibility and control.

10. How do you stay updated with the latest advancements and technologies in soldering?

- Attending Industry Events: Participating in conferences, workshops, and exhibitions to connect with professionals and learn about new techniques.

- Reading Technical Literature: Reviewing journals, articles, and white papers to stay abreast of research and developments in soldering.

- Online Resources: Utilizing online forums, webinars, and manufacturer websites to gather information and exchange knowledge.

- In-house Training: Seeking opportunities for training and development within the organization to enhance skills and stay updated with advancements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Soldering Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Soldering Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Soldering Machine Setters are highly skilled professionals responsible for the setup and operation of sophisticated soldering machines used in the manufacturing of electronic components and assemblies. Their primary duties involve ensuring the equipment operates at optimal levels and produces high-quality soldered connections.

1. Machine Setup and Optimization

A critical responsibility of Soldering Machine Setters is setting up and optimizing soldering machines according to specific job requirements. They fine-tune machine parameters such as temperature, speed, and dwell time to achieve the desired solder joint quality. They also calibrate and maintain equipment to minimize downtime and ensure consistent performance.

2. Solder Joint Inspection and Quality Control

Soldering Machine Setters monitor the soldering process closely and conduct thorough solder joint inspections to ensure the integrity and reliability of the connections. They use specialized tools and techniques to identify and correct any defects or inconsistencies. They also follow established quality control procedures to maintain high standards and mitigate risks.

3. Troubleshooting and Maintenance

Soldering Machine Setters are skilled in troubleshooting and resolving technical issues that may arise during the soldering process. They perform routine maintenance tasks, such as cleaning and lubricating equipment, to minimize downtime and extend the machine’s lifespan. They also work closely with maintenance technicians to address more complex problems and ensure optimal machine performance.

4. Process Improvement and Innovation

Soldering Machine Setters continuously seek ways to improve the efficiency and accuracy of the soldering process. They may suggest improvements to machine setup, optimization techniques, or quality control procedures. They also stay up-to-date with industry best practices and advancements to enhance their knowledge and contribute to the overall success of the manufacturing process.

Interview Tips

Preparing thoroughly for a Soldering Machine Setter interview is crucial for success. Here are some valuable tips to help candidates excel:

1. Research the Industry and Company

Candidates should familiarize themselves with the electronics manufacturing industry trends, common soldering techniques, and the company’s products and processes. This knowledge demonstrates a genuine interest and eagerness to contribute to the team’s success.

2. Highlight Relevant Skills and Experience

Emphasizing specific skills and experience related to soldering machine setup, operation, and maintenance is essential. Candidates should provide concrete examples of their proficiency in troubleshooting, quality control, and process improvement.

3. Prepare for Technical Questions

Interviewers often ask technical questions to assess a candidate’s understanding of soldering principles and machine operation. Candidates should be comfortable discussing topics such as solder alloy selection, flux types, and techniques for achieving optimal solder joint quality.

4. Demonstrate Problem-Solving Abilities

Soldering Machine Setters must be skilled in resolving technical issues. Candidates should prepare for scenario-based questions that test their ability to identify and troubleshoot potential problems during the soldering process. Providing examples of their problem-solving skills in previous roles is beneficial.

5. Emphasize Attention to Detail and Quality Assurance

Accuracy and precision are paramount in soldering. Candidates should convey their meticulous nature and commitment to quality assurance. They should highlight their ability to perform thorough solder joint inspections and adhere strictly to established quality control guidelines.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Soldering Machine Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.