Are you gearing up for an interview for a Soldering Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Soldering Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

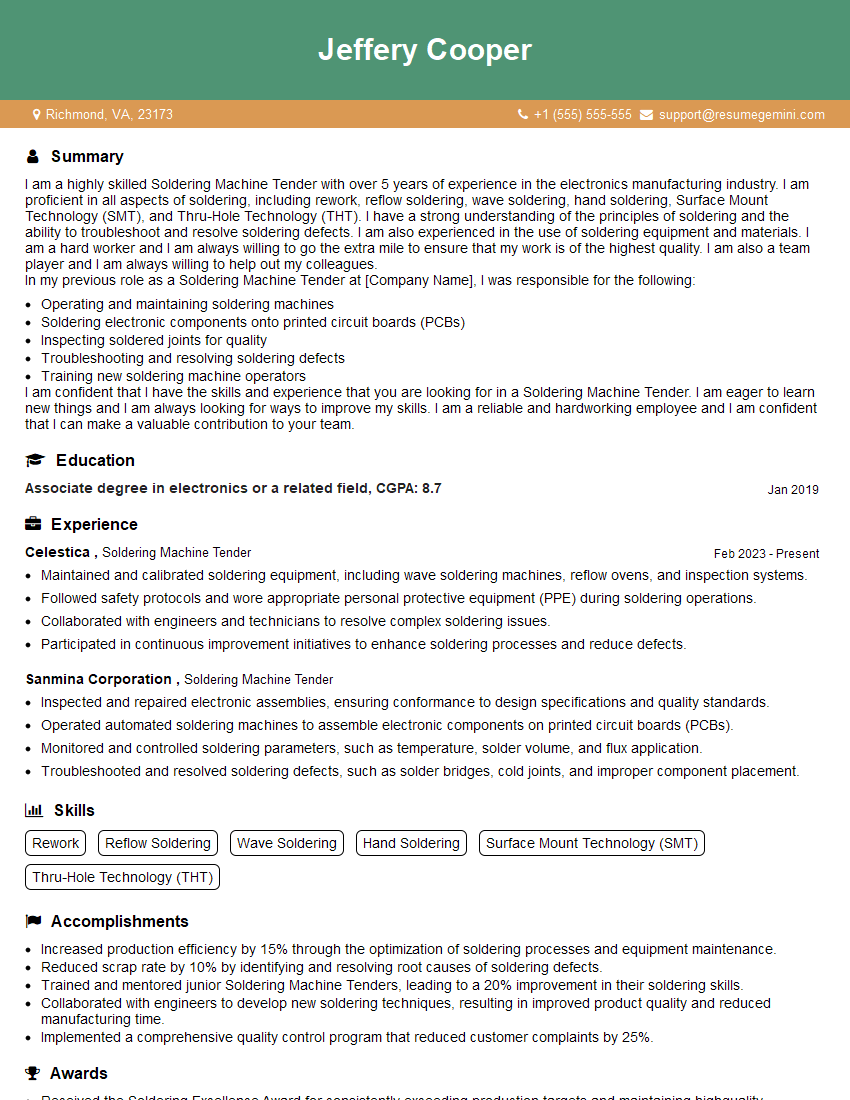

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Soldering Machine Tender

1. Describe the key responsibilities of a Soldering Machine Tender.

As a Soldering Machine Tender, my responsibilities primarily involve operating and maintaining the soldering machine to ensure efficient and high-quality production. Key duties include:

- Operating the soldering machine to join electronic components on printed circuit boards (PCBs).

- Monitoring solder flow and temperature to ensure proper adhesion and prevent defects.

- Performing quality inspections on soldered joints to meet established standards.

- Maintaining and troubleshooting the soldering machine, including cleaning, lubrication, and part replacement.

- Following safety regulations and adhering to quality control procedures.

2. Explain the different types of soldering methods and their applications.

Wave Soldering

- Used for large-scale production of PCBs.

- Involves passing the PCB through a molten solder wave.

Reflow Soldering

- Suitable for surface mount technology (SMT) components.

- Uses controlled temperature profiles to melt solder paste and form connections.

Hand Soldering

- Employed for small batches or specialized projects.

- Involves using a soldering iron and solder wire to make manual connections.

3. How do you ensure the quality of soldered joints?

Ensuring the quality of soldered joints is crucial. I follow a comprehensive approach that includes:

- Visual inspection: Examining joints for proper shape, size, and uniformity.

- Electrical testing: Using continuity and resistance tests to verify electrical connections.

- Mechanical testing: Applying stress or vibration to test joint strength and integrity.

- Adhering to established quality control standards and specifications.

- Continuous monitoring of the soldering process to identify and mitigate any potential defects.

4. How do you troubleshoot common soldering problems?

Troubleshooting soldering problems requires a systematic approach. I typically follow these steps:

- Identify the problem: Observe the symptoms and gather information about the affected component or joint.

- Check the soldering equipment: Ensure the soldering iron or machine is functioning properly and calibrated correctly.

- Inspect the solder: Verify the solder’s quality and composition, ensuring it meets the required specifications.

- Examine the PCB: Inspect for any damage or contamination that may affect the solder’s adhesion.

- Clean and re-solder: Clean the affected area and re-solder the joint using proper techniques to ensure a strong and reliable connection.

5. How do you maintain and calibrate a soldering machine?

Regular maintenance and calibration are essential for optimal machine performance. My maintenance routine includes:

- Daily cleaning: Removing flux residue, solder spatter, and debris from the machine’s components.

- Periodic lubrication: Applying lubricants to moving parts to minimize friction and wear.

- Calibration: Using specialized equipment to ensure the machine’s temperature, feed rate, and other parameters meet the desired specifications.

- Preventive maintenance: Scheduling regular inspections and servicing to identify and address potential issues before they impact production.

6. What safety precautions do you observe while operating a soldering machine?

Safety is paramount when operating soldering machines. I strictly adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and a lab coat.

- Ensuring the workspace is well-ventilated and free of fumes and smoke.

- Using proper grounding techniques to prevent electrical hazards.

- Handling hot equipment with care and avoiding contact with molten solder.

- Following established safety protocols and emergency procedures.

7. How do you stay updated with the latest soldering techniques and industry best practices?

To stay abreast of advancements in soldering technology, I engage in continuous learning and professional development. I utilize various resources, such as:

- Attending industry workshops, conferences, and seminars.

- Reading technical articles and journals.

- Seeking guidance from experienced professionals and subject matter experts.

- Exploring online resources and forums for knowledge sharing and discussions.

8. Describe the importance of solderability testing in ensuring the quality of soldered joints.

Solderability testing is crucial for evaluating the wettability and adhesion characteristics of materials used in soldering. By conducting solderability tests, I can:

- Determine the suitability of components and materials for soldering processes.

- Identify and mitigate potential soldering defects, such as poor wetting or solder bridging.

- Optimize soldering parameters, such as temperature and dwell time, to achieve optimal joint quality.

- Ensure the reliability and durability of soldered connections.

9. How do you handle high-volume soldering operations efficiently while maintaining quality standards?

In high-volume soldering environments, efficiency and quality are paramount. I employ the following strategies:

- Optimizing machine settings and processes to minimize cycle time without compromising quality.

- Implementing automated inspection systems to ensure consistent and reliable joint verification.

- Training and empowering team members to perform soldering tasks effectively and efficiently.

- Establishing clear quality control protocols and monitoring production processes to identify and address potential issues promptly.

10. What are some innovative soldering techniques that you have implemented in your previous roles?

In my previous role at [company name], I successfully implemented the following innovative soldering techniques:

- Incorporated selective soldering using a laser soldering system to achieve precise joint formation and reduce solder waste.

- Developed a customized soldering fixture to increase production speed and ensure consistent joint quality for complex assemblies.

- Integrated machine learning algorithms into the soldering process to monitor joint characteristics and predict potential defects, enhancing overall production efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Soldering Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Soldering Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Soldering Machine Tender has various job responsibilities. These mainly include:

1. Prepare and set up soldering machines

Soldering Machine Tenders are responsible for preparing and setting up soldering machines according to the job requirements.

- Install soldering tips and adjust temperature settings.

- Thread solder wire through the machine and ensure it is properly aligned.

- Inspect and clean soldering machines to maintain optimal performance.

2. Monitor and control soldering processes

Monitoring and controlling soldering processes is a crucial aspect of the job:

- Monitor and adjust solder flow to achieve desired results.

- Observe product quality and make necessary adjustments to the process.

- Troubleshoot any issues that arise and take corrective actions.

3. Inspect and test solder joints

Inspecting and testing solder joints is essential for quality assurance:

- Check solder joints for defects, such as voids, bridges, or cold joints.

- Test solder joints for electrical conductivity and mechanical strength.

- Maintain records of inspection and test results for quality control.

4. Perform maintenance and troubleshooting

Regular maintenance and troubleshooting ensure the smooth operation of soldering machines:

- Clean and lubricate soldering machines regularly.

- Identify and repair any mechanical or electrical faults.

- Monitor and maintain inventory of soldering supplies.

Interview Preparation Tips

To ace an interview for a Soldering Machine Tender position, it is essential to prepare thoroughly. Here are some tips:

1. Research the company and position

Research the company’s products, services, and industry to demonstrate your interest and understanding.

- Read the job description carefully to identify the specific requirements and expectations.

- Visit the company’s website and social media pages to gather insights into its culture and values.

2. Practice your answers to common interview questions

Prepare for common interview questions related to your skills, experience, and motivations.

- Explain your understanding of the soldering process and techniques.

- Describe your experience in operating and maintaining soldering machines.

- Provide examples of your ability to inspect and test solder joints for quality.

3. Highlight your problem-solving abilities

Emphasize your ability to identify and resolve problems during the soldering process.

- Share instances where you successfully troubleshoot and resolved issues with soldering machines.

- Explain how you handle unexpected situations and ensure product quality.

4. Show your attention to detail

Convince the interviewer of your meticulous nature and attention to detail.

- Highlight your experience in following precise instructions and maintaining a clean work environment.

- Explain your commitment to quality assurance and adherence to industry standards.

5. Be enthusiastic and professional

Demonstrate your enthusiasm for the position and willingness to learn and grow.

- Express your interest in the soldering process and your desire to contribute to the company’s success.

- Dress professionally and maintain a positive and respectful attitude throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Soldering Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!