Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Soldering Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Soldering Technician so you can tailor your answers to impress potential employers.

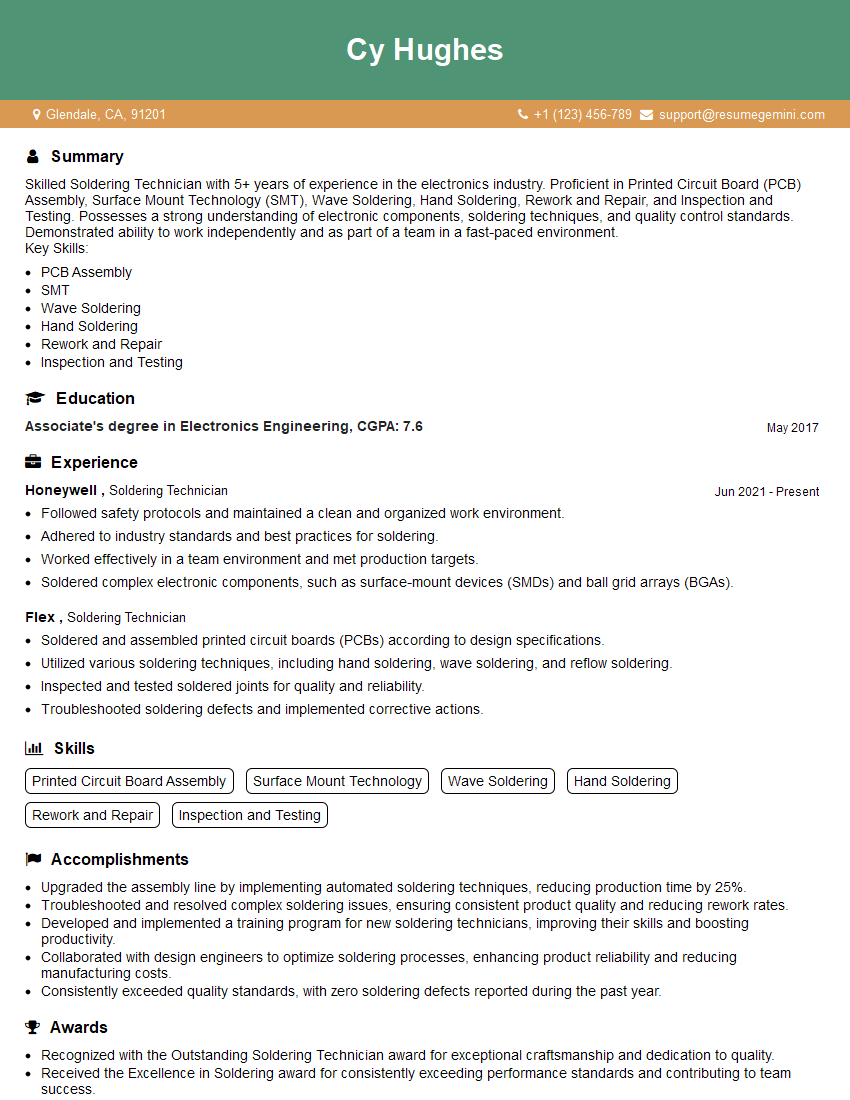

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Soldering Technician

1. What are the different types of soldering techniques?

There are various soldering techniques used in the industry, here are some common ones:

- Hand soldering: This is the most basic and widely used technique. It involves using a soldering iron to apply solder to the connection points.

- Wave soldering: This technique uses a wave of molten solder to solder multiple components simultaneously. It is suitable for high-volume production.

- Reflow soldering: This technique uses a controlled heating process to melt the solder paste applied to the circuit board. It is often used in surface mount technology (SMT).

- Vapor phase soldering: This technique uses a vapor phase to heat the assembly and melt the solder. It provides consistent and precise soldering.

2. What are the key factors that affect the quality of a solder joint?

Joint preparation

- Proper cleaning and preparation of the surfaces to be joined is crucial for good adhesion.

- Ensuring the correct alignment and fit of the components is also essential.

Solder selection

- Choosing the right type of solder with the appropriate melting point and composition is important.

- The diameter of the solder wire should be suitable for the size of the joint.

Soldering technique

- Using proper soldering techniques, such as controlling the temperature and applying the solder smoothly, is vital.

- Avoiding over-soldering or cold joints is essential for a reliable connection.

3. What are the common defects that can occur in soldering?

Some common soldering defects include:

- Cold joints: These occur when the solder does not properly melt and fuse with the metals being joined, resulting in a weak connection.

- Over-soldering: This can lead to solder bridges between adjacent components or excessive solder accumulation, causing shorts or reliability issues.

- Insufficient solder: When there is insufficient solder, the joint may not have enough strength and could fail under stress.

- Solder voids: These are air pockets or gaps within the solder joint, reducing its mechanical strength and electrical conductivity.

4. How do you inspect and test solder joints?

Inspecting solder joints involves visual examination using magnification tools such as microscopes or magnifying glasses to check for defects like cold joints, over-soldering, or voids.

Testing solder joints can include:

- Mechanical testing: Applying force to the joint to assess its strength and durability.

- Electrical testing: Measuring the electrical continuity and resistance of the joint to ensure proper conductivity.

- Environmental testing: Exposing the joint to various conditions, such as temperature extremes or humidity, to evaluate its reliability.

5. What are the safety precautions that should be followed when soldering?

When soldering, it is essential to follow safety precautions to prevent accidents or injuries:

- Wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a fume extractor is crucial.

- Ensuring proper ventilation to avoid inhaling harmful fumes is important.

- Using soldering irons with proper grounding to prevent electrical shocks is essential.

- Handling molten solder with care to avoid burns is vital.

- Keeping the work area clean and organized to prevent accidents is important.

6. What are the different types of soldering equipment?

Soldering equipment includes:

- Soldering irons: These are the primary tools used for soldering, with various types available, such as pencil irons, soldering guns, and desoldering tools.

- Solder: Different types of solder are available, such as lead-based, lead-free, and flux-cored solder.

- Soldering fluxes: These are used to clean and prepare the surfaces before soldering, improving the solderability.

- Desoldering pumps or wicks: These tools are used to remove solder from joints when necessary.

- Magnifying tools: Microscopes or magnifying glasses are used to inspect solder joints for defects.

7. How do you maintain and calibrate soldering equipment?

Maintaining and calibrating soldering equipment is important for accurate and efficient soldering:

- Regularly cleaning the soldering iron tip to remove oxides and ensure proper heat transfer is essential.

- Calibrating the soldering iron temperature to match the melting point of the solder being used is important.

- Inspecting and replacing worn-out or damaged parts, such as soldering iron tips or cords, is crucial.

8. What are the challenges and troubleshooting tips for soldering?

Challenges

- Creating strong and reliable solder joints consistently.

- Avoiding common defects such as cold joints, over-soldering, or solder voids.

- Working with different types of materials and components.

Troubleshooting tips

- Ensuring proper preparation and cleaning of surfaces before soldering.

- Using the correct type and amount of solder.

- Controlling the soldering temperature and applying heat evenly.

- Understanding the characteristics of different metals and their soldering requirements.

9. How do you stay updated with the latest soldering techniques and industry standards?

To stay updated with the latest soldering techniques and industry standards:

- Attending industry conferences, workshops, or training programs is beneficial.

- Reading technical articles, journals, or online resources can provide valuable information.

- Following industry organizations and participating in online forums can help stay connected with the latest developments.

10. What qualities and skills make a successful soldering technician?

- Strong attention to detail and precision in handling delicate components.

- Excellent hand-eye coordination and dexterity for handling soldering equipment.

- Understanding of soldering principles, materials, and techniques.

- Ability to read and interpret technical drawings and specifications.

- Commitment to quality and adherence to safety regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Soldering Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Soldering Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Soldering Technician plays a crucial role in the assembly and repair of electronic devices and components. Their primary responsibilities encompass:

1. Soldering and Desoldering Activities

• Executing precise soldering and desoldering operations to connect electrical components and printed circuit boards (PCBs)

• Ensuring secure and reliable electrical connections while adhering to industry standards

2. Inspection and Quality Control

• Conducting thorough inspections of soldered joints to identify and rectify defects

• Adhering to quality control protocols to ensure the integrity and performance of electronic assemblies

3. Equipment Maintenance

• Maintaining and calibrating soldering equipment, including soldering irons, desoldering stations, and inspection tools

• Monitoring equipment performance to prevent malfunctions and ensure efficient operations

4. Material Management

• Managing inventory of soldering materials, including solder wire, flux, and cleaning agents

• Ensuring adequate supplies for continuous production and repair activities

5. Documentation and Training

• Maintaining accurate records of soldering processes, including work orders and inspection reports

• Providing training and support to junior technicians or other team members to enhance skills and knowledge

Interview Tips

To ace the interview for a Soldering Technician position, meticulous preparation is essential. Consider the following tips:

1. Research the Company and Position

• Familiarize yourself with the company’s background, products/services, and industry reputation

• Review the job description thoroughly to understand specific requirements and responsibilities

2. Highlight Relevant Skills and Experience

• Emphasize your technical proficiency in soldering, desoldering, and inspection techniques

• Showcase your experience in working with different types of electronic components and PCBs

• Quantify your accomplishments and provide concrete examples of your contributions

3. Practice Interview Questions

• Anticipate common interview questions and prepare thoughtful responses

• Utilize the STAR method (Situation, Task, Action, Result) to effectively convey your experiences and skills

4. Emphasize Quality and Precision

• Express your commitment to delivering high-quality work and meeting industry standards

• Highlight your attention to detail and ability to work meticulously with small components

5. Prepare Questions for the Interviewer

• Demonstrate your interest and engagement by asking thoughtful questions about the company, the position, and the industry

• This shows that you are genuinely interested in the opportunity and eager to learn more

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Soldering Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Soldering Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.