Feeling lost in a sea of interview questions? Landed that dream interview for Sole Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sole Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

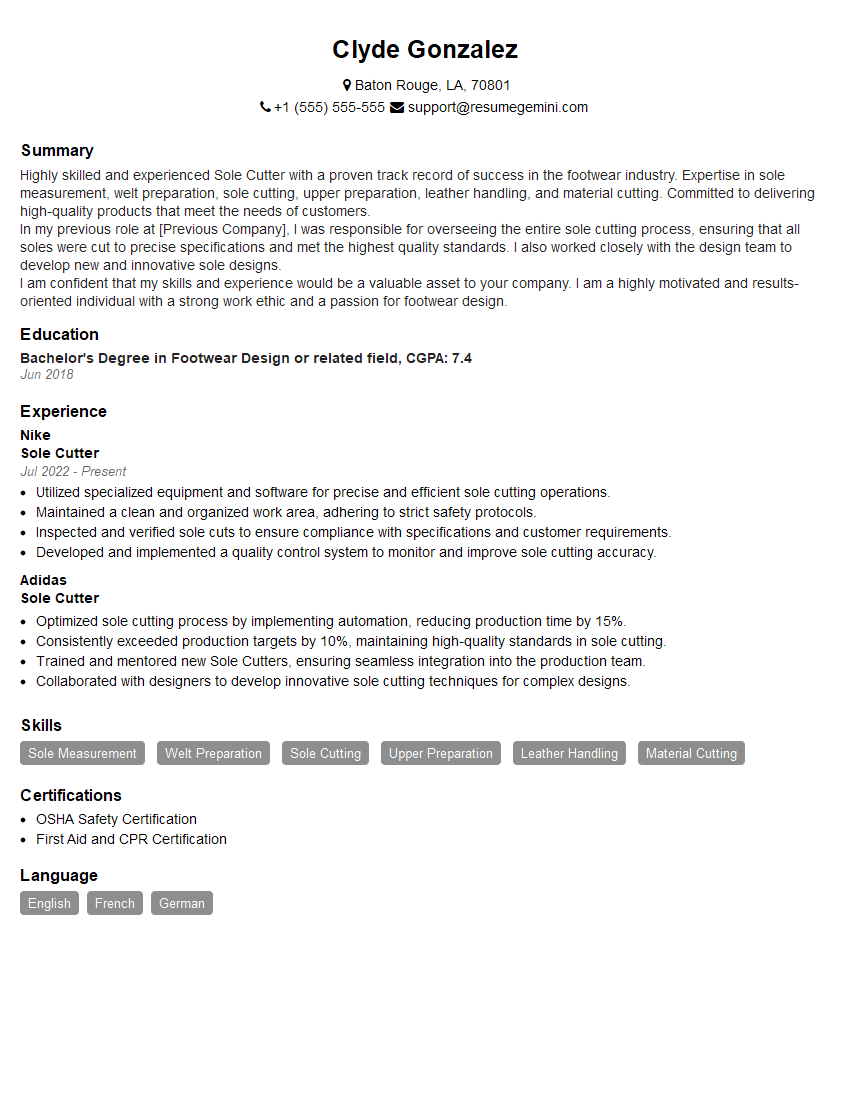

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sole Cutter

1. What are the essential tools and equipment for precise and efficient sole cutting?

In my experience, the key tools for sole cutting include:

- Sharp, high-quality cutting knife

- Cutting mat with precise measurements

- Steel ruler and accurate measuring tape

- Sole marking pen or chalk

- Handheld or electric cutting machine for consistent accuracy

2. How do you ensure the accuracy of the cut according to the pattern and design specifications?

Precision Measuring and Marking

- Accurately measure the pattern and transfer it to the sole material.

- Use a sharp marking pen or chalk to outline the cut lines.

Steady and Controlled Cutting

- Secure the material firmly to the cutting mat to prevent movement.

- Use a sharp cutting knife and maintain a consistent cutting pressure.

3. What are the different techniques for cutting different types of sole materials (e.g., leather, rubber, EVA)?

The cutting technique varies depending on the material’s properties:

- Leather: Requires a sharp, sharp knife and precise cuts.

- Rubber: May require a thicker blade and slower, controlled cutting.

- EVA: Can be cut using a handheld or electric cutting machine for efficiency.

4. How do you handle and prepare the sole material to ensure a smooth and clean cut?

Preparing the sole material is crucial for a precise cut:

- Conditioning: Allow the material to reach room temperature for flexibility.

- Flattening: Remove any wrinkles or creases to ensure a flat surface.

- Marking: Clearly mark the cutting lines using a template or pattern.

5. What are the safety precautions and best practices to follow during sole cutting operations?

- Wear appropriate PPE, including gloves and safety glasses.

- Ensure good lighting and ventilation in the work area.

- Use sharp cutting tools and handle them cautiously.

- Keep the work area clean and free from tripping hazards.

- Follow established safety protocols and seek assistance when necessary.

6. How do you maintain and sharpen cutting tools to ensure optimal performance?

- Regularly clean and oil cutting knives to prevent rust and maintain sharpness.

- Use whetstones or honing rods to sharpen blades to the desired angle.

- Inspect tools for any damage or wear and replace them promptly.

- Follow manufacturer’s guidelines for specific tool maintenance.

7. How do you handle and store sole materials after cutting to maintain their quality and prevent damage?

- Stacking: Stack cut soles flat and evenly to prevent deformation.

- Moisture Control: Store soles in a cool, dry environment to avoid moisture absorption.

- Protection from Damage: Use protective sheets or boxes to prevent scratches or tears.

- Labeling: Clearly label soles with relevant information for easy identification.

8. What are the common challenges and troubleshooting techniques in sole cutting?

- Inaccurate Cuts: Recheck measurements and ensure proper marking and cutting techniques.

- Rough Edges: Use sharper blades or adjust cutting pressure for smoother edges.

- Material Deformations: Ensure proper conditioning and handling of the sole material.

- Tool Issues: Regularly maintain and sharpen cutting tools, and replace them if necessary.

9. How do you ensure consistency and quality in your sole cutting work?

- Attention to Detail: Focus on precision and accuracy at every step.

- Standardized Processes: Establish clear and consistent cutting procedures.

- Quality Control: Regularly inspect cut soles to ensure they meet specifications.

- Continuous Improvement: Seek feedback and implement improvements to enhance quality.

10. How do you stay updated with the latest techniques and advancements in sole cutting?

- Industry Publications: Read trade magazines and articles for new cutting methods.

- Attending Workshops and Seminars: Participate in industry events to learn from experts.

- Online Research: Explore online resources and forums for cutting techniques and best practices.

- Collaboration: Connect with other sole cutters to share knowledge and insights.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sole Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sole Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sole Cutter is responsible for cutting and shaping the soles of footwear. They use a variety of tools and techniques to cut, trim, and finish the soles of shoes, boots, and other footwear products.

1. Cutting and Shaping Soles

The primary responsibility of a Sole Cutter is to cut and shape the soles of footwear. They use a variety of cutting tools, such as knives, shears, and saws, to cut the soles to the desired shape and size.

- Use knives, shears, and saws to cut soles to the desired shape and size.

- Follow patterns and templates to ensure accuracy and precision.

2. Trimming and Finishing Soles

Once the soles have been cut, they must be trimmed and finished. Sole Cutters use a variety of tools, such as sanders, grinders, and buffers, to trim and finish the soles to the desired smoothness and texture.

- Use sanders, grinders, and buffers to trim and finish soles to the desired smoothness and texture.

- Apply adhesives and other materials to attach soles to uppers.

3. Inspecting Soles

Before the soles are attached to the uppers of the footwear, they must be inspected to ensure that they meet the required quality standards. Sole Cutters visually inspect the soles for any defects, such as cuts, cracks, or unevenness.

- Visually inspect soles for any defects, such as cuts, cracks, or unevenness.

- Reject or rework soles that do not meet the required quality standards.

4. Maintaining Equipment

Sole Cutters are responsible for maintaining the equipment that they use. This includes cleaning and lubricating the equipment, as well as making minor repairs.

- Clean and lubricate equipment to ensure proper operation.

- Make minor repairs to equipment, such as replacing blades or belts.

Interview Tips

Preparing for an interview can help you make a good impression on the interviewer and increase your chances of getting the job. Here are a few tips to help you prepare for an interview for a Sole Cutter position:

1. Research the Company and the Position

Take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read online reviews of the company to get an idea of the company’s culture and work environment.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked in an interview for a Sole Cutter position. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Tell me about your experience in cutting and shaping soles.

- What are your strengths and weaknesses as a Sole Cutter?

- Why are you interested in working for this company?

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of an interview shows that you are interested in the position and that you have done your research. It also gives you an opportunity to learn more about the company and the position.

- What is the company’s culture like?

- What are the challenges and opportunities associated with this position?

- What are the company’s growth plans for the future?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Arrive for your interview on time, or even a few minutes early.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sole Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!