Feeling lost in a sea of interview questions? Landed that dream interview for Solid Propellant Processor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Solid Propellant Processor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

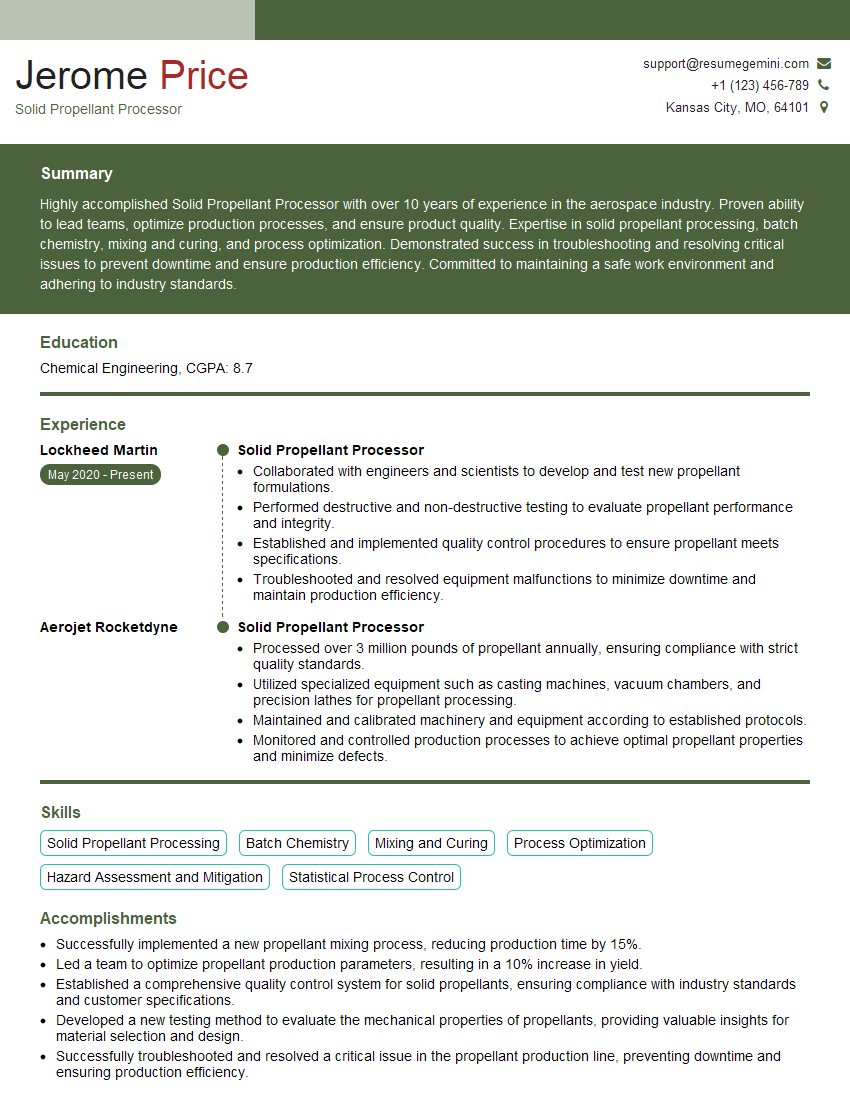

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Solid Propellant Processor

1. What are the different types of solid propellants and their compositions?

Solid propellants are classified into two main types: composite and double base. Composite propellants consist of an oxidizer and a fuel, while double base propellants consist of a nitrocellulose and nitroglycerin mixture. Some of the common oxidizers used in solid propellants include ammonium perchlorate, potassium nitrate, and ammonium nitrate. Common fuels include aluminum, carbon black, and hydroxyl-terminated polybutadiene (HTPB).

2. What is the difference between a propellant and an explosive?

Burn Rate

- Propellants are designed to burn at a controlled rate, while explosives are designed to detonate.

Pressure and Temperature

- Propellants produce lower pressure and temperature than explosives.

Composition

- Propellants typically contain a fuel and an oxidizer, while explosives typically contain a single substance that can undergo a rapid exothermic reaction.

Applications

- Propellants are used in rockets and missiles, while explosives are used in demolition and mining.

3. What are the key factors that affect the performance of a solid propellant?

The key factors that affect the performance of a solid propellant include:

- Composition: The composition of a propellant determines its burn rate, specific impulse, and other properties.

- Processing: The processing of a propellant can affect its physical and mechanical properties.

- Environmental conditions: The environmental conditions in which a propellant is used can affect its performance.

4. What are the safety precautions that need to be taken when handling solid propellants?

Solid propellants are energetic materials that can be dangerous if not handled properly. The following safety precautions should be taken when handling solid propellants:

- Store propellants in a cool, dry place away from heat and ignition sources.

- Do not smoke or use open flames near propellants.

- Wear appropriate personal protective equipment (PPE) when handling propellants.

- Follow all manufacturer’s instructions for handling and storage.

5. What are the different techniques used for the characterization of solid propellants?

The different techniques used for the characterization of solid propellants include:

- Thermal analysis (e.g., differential scanning calorimetry, thermogravimetric analysis)

- Mechanical testing (e.g., tensile testing, flexural testing)

- Spectroscopic techniques (e.g., infrared spectroscopy, Raman spectroscopy)

- Microscopy (e.g., optical microscopy, scanning electron microscopy)

6. What are the common defects that can occur during the processing of solid propellants?

The common defects that can occur during the processing of solid propellants include:

- Voids: Voids are empty spaces within the propellant that can lead to reduced performance.

- Cracks: Cracks are breaks in the propellant that can lead to premature failure.

- Delamination: Delamination is the separation of layers within the propellant.

- Inclusions: Inclusions are foreign objects that can become trapped in the propellant during processing.

7. What are the quality control measures that are used to ensure the quality of solid propellants?

The quality control measures that are used to ensure the quality of solid propellants include:

- Raw material testing

- In-process testing

- Final product testing

8. What are the different methods used to manufacture solid propellants?

The different methods used to manufacture solid propellants include:

- Casting: Casting is a process in which a propellant is poured into a mold and allowed to cure.

- Extrusion: Extrusion is a process in which a propellant is forced through a die to create a desired shape.

- Pressing: Pressing is a process in which a propellant is pressed into a desired shape using a mold and a press.

9. What are the challenges involved in the development of new solid propellants?

The challenges involved in the development of new solid propellants include:

- Achieving high performance: New propellants must meet or exceed the performance of existing propellants.

- Ensuring safety: New propellants must be safe to handle and use.

- Reducing cost: New propellants must be cost-effective to produce.

10. What is the future of solid propellant technology?

The future of solid propellant technology is promising. New propellants are being developed that offer higher performance, improved safety, and lower cost. These propellants will enable the development of new and more efficient rockets and missiles.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Solid Propellant Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Solid Propellant Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Solid Propellant Processors execute a variety of vital tasks in the aerospace industry. Their responsibilities encompass the handling, processing, and testing of solid propellants used in rockets, missiles, and other propulsion systems. These individuals ensure that the propellants are safely and efficiently manufactured, inspected, and prepared for use, contributing to the success of spacecraft launches and other critical aerospace missions.

1. Propellant Handling and Processing

Solid Propellant Processors are responsible for the safe and efficient handling of solid propellants. This includes receiving, storing, and transporting propellants according to established protocols. They also perform various processing tasks, such as mixing, casting, curing, and machining propellants to meet specific requirements.

2. Quality Control and Inspection

Ensuring the quality of solid propellants is paramount. Solid Propellant Processors conduct rigorous inspections and tests throughout the processing stages to verify the propellants meet the required specifications. They utilize specialized equipment and techniques to assess propellant properties, such as density, burn rate, and mechanical strength.

3. Equipment Maintenance and Troubleshooting

Solid Propellant Processors are responsible for maintaining and troubleshooting the equipment used in propellant processing. This includes performing routine maintenance, calibrating instruments, and identifying and resolving any issues that may arise during processing. They ensure that the equipment is operating optimally and safely.

4. Safety and Compliance

Solid Propellant Processors adhere to strict safety protocols and regulations governing the handling and processing of propellants. They are trained in hazardous materials handling, emergency response procedures, and environmental protection measures. Additionally, they ensure compliance with industry standards and government regulations to maintain a safe and compliant work environment.

Interview Tips

Preparing for an interview for a Solid Propellant Processor position requires a combination of technical knowledge and practical experience. Here are some tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company you are interviewing with, its products, and the specific requirements of the Solid Propellant Processor role. Researching the company’s website, LinkedIn page, and industry publications will provide you with insights that can help you tailor your answers.

2. Highlight Relevant Experience and Skills

Emphasize your experience in propellant handling, processing, inspection, and safety. Quantify your accomplishments and provide specific examples of your contributions to previous projects. Highlight any specialized skills or certifications you possess, such as hazardous materials handling or quality control techniques.

3. Showcase Your Problem-Solving Abilities

Solid Propellant Processors often encounter challenges during propellant processing. In the interview, be prepared to discuss situations where you identified and resolved problems effectively. Describe the steps you took, the tools you used, and the outcomes you achieved.

4. Demonstrate Safety and Compliance Knowledge

Safety is paramount in the aerospace industry. Highlight your understanding of safety protocols, emergency response procedures, and environmental regulations. Discuss your experience in implementing these measures and ensuring compliance in your previous roles.

Next Step:

Now that you’re armed with the knowledge of Solid Propellant Processor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Solid Propellant Processor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini