Are you gearing up for a career in Solid Surface Fabricator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Solid Surface Fabricator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

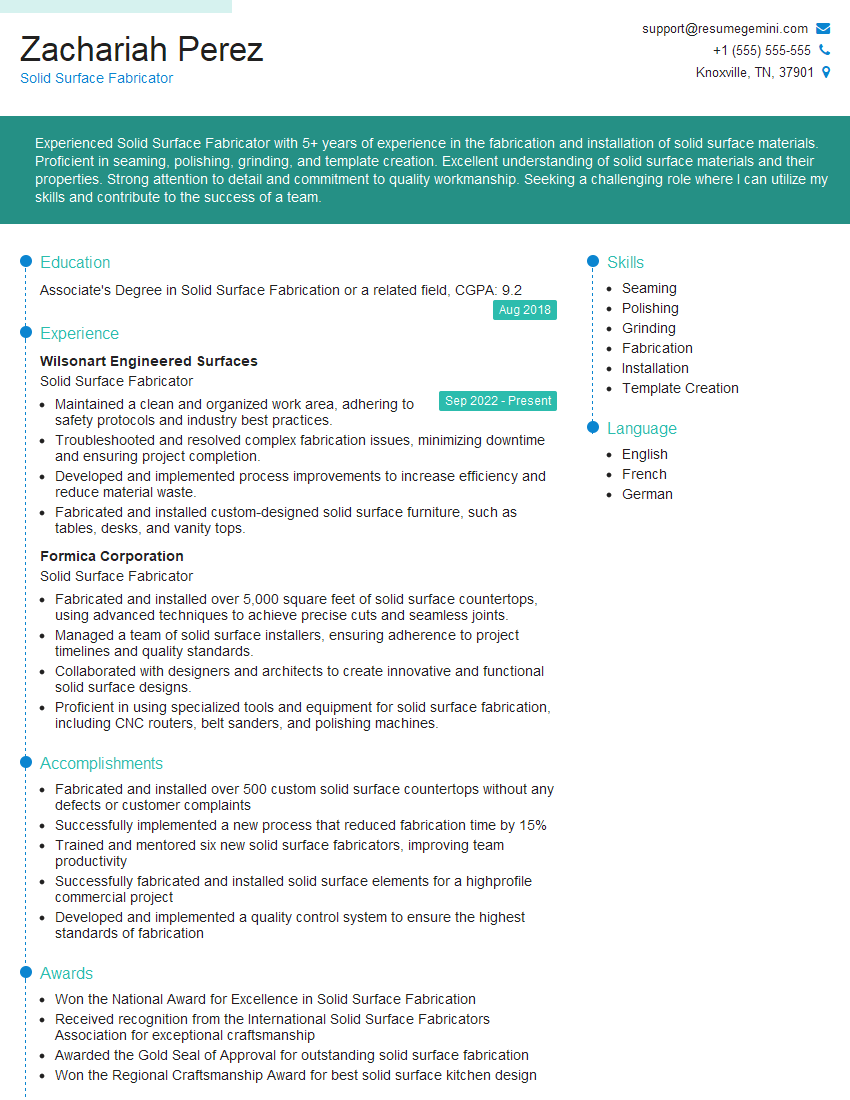

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Solid Surface Fabricator

1. What are the different types of solid surface materials, and what are their key characteristics?

- Acrylic-based solid surfaces: Made primarily of acrylic resin, they are known for their durability, resistance to scratches and stains, and ability to be thermoformed into complex shapes.

- Polyester-based solid surfaces: Composed primarily of polyester resin, they are typically more economical than acrylic-based solid surfaces, but may be less resistant to heat and chemicals.

- Epoxy-based solid surfaces: Formulated with epoxy resins, they are highly resistant to chemicals and heat, making them suitable for industrial applications.

2. What are the standard sizes and thicknesses available for solid surface sheets?

- Standard sizes: Typically come in 4 ft. x 8 ft., 5 ft. x 10 ft., and 6 ft. x 12 ft. sheets.

- Standard thicknesses: Usually range from 1/4 inch to 1-1/2 inches, with 1/2 inch being the most common.

3. How do you determine the appropriate thickness for a solid surface countertop?

- Consider the intended use of the countertop: heavier applications, such as kitchen countertops, require thicker material to ensure durability.

- Calculate the span between supports: larger spans may necessitate thicker material to prevent sagging.

- Refer to manufacturer’s recommendations: they often provide guidelines on appropriate thicknesses for different applications.

4. Describe the different methods used to join solid surface materials seamlessly.

- Chemical bonding: Using a specialized adhesive, two solid surface pieces are chemically fused together for a seamless joint.

- Mechanical fasteners: Screws or bolts may be used to connect solid surface pieces, but visible seams may result.

- Heat welding: By applying heat and pressure, solid surface pieces can be welded together, creating a strong and nearly invisible bond.

5. How do you ensure proper ventilation when installing solid surface materials?

- Open windows and doors to allow for adequate airflow.

- Use fans or ventilation systems to exhaust fumes and odors.

- Wear appropriate personal protective equipment (PPE), such as respirators, to prevent inhalation of harmful fumes.

6. What are the recommended maintenance procedures for solid surface materials to keep them in optimal condition?

- Clean regularly with mild soap and water.

- Use non-abrasive cleaning pads or cloths to avoid scratching.

- Avoid using harsh chemicals or abrasive cleaners.

- Apply a protective sealer as per manufacturer’s instructions to enhance stain resistance and longevity.

7. Describe the process of repairing a scratch or damage to a solid surface countertop.

- For minor scratches: Use a fine-grit sandpaper or a rubbing compound to gently rub the scratch away.

- For deeper scratches: Fill the scratch with a color-matched repair kit or consult a professional repair technician.

- For large damages: Replace the damaged section or consult a professional fabricator for repair options.

8. How do you ensure accurate templating and fabrication of solid surface countertops to fit specific dimensions and shapes?

- Templating: Use precise measuring tools to create a template that accurately reflects the shape and dimensions of the countertop area.

- Fabrication: Transfer the template onto the solid surface material and cut and shape it using specialized tools.

- Fitting: Carefully fit the fabricated countertop into the designated area, ensuring a precise fit.

9. What are some common challenges encountered during solid surface fabrication, and how do you address them?

- Seaming: Ensuring seamless joints requires proper preparation, joining techniques, and attention to detail.

- Color matching: Achieving consistent color throughout the countertop requires careful selection of materials and proper fabrication techniques.

- Handling large or complex shapes: Fabricating countertops with intricate shapes requires specialized tools and techniques to ensure accuracy and precision.

10. Stay updated with the latest trends and technologies in the solid surface industry, and how do you incorporate them into your work?

- Attend industry events and exhibitions to learn about new materials and techniques.

- Read trade publications and online resources to stay informed about the latest advancements.

- Collaborate with other fabricators and industry professionals to exchange knowledge and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Solid Surface Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Solid Surface Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Solid Surface Fabricators are responsible for creating and installing solid surface countertops, vanities, and other fixtures. They use specialized tools and techniques to cut, shape, and finish the solid surface material, ensuring that it meets the customer’s specifications.

1. Fabrication and Installation

The primary responsibility of a Solid Surface Fabricator is to fabricate and install solid surface products. This involves:

- Measuring and cutting the material to the desired shape and size

- Adhering the material to the substrate using adhesives or other bonding agents

- Seaming the material to create a seamless appearance

- Polishing and finishing the material to the desired sheen

2. Reading and Interpreting Blueprints

Solid Surface Fabricators must be able to read and interpret blueprints to ensure that they are following the customer’s specifications. They must also be able to identify and locate the correct materials for the job.

3. Knowledge of Solid Surface Materials

Solid Surface Fabricators must have a thorough knowledge of solid surface materials, including their properties, strengths, and weaknesses. They must also be able to advise customers on the best type of solid surface material for their specific needs.

4. Safety and Compliance

Solid Surface Fabricators must follow all safety and compliance regulations, including those related to the handling of hazardous materials. They must also be able to work independently and as part of a team.

Interview Tips

To ace your interview for a Solid Surface Fabricator position, there are several tips you can follow.

1. Research the Company and Position

Before your interview, take the time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You should also be prepared to answer questions about your experience and qualifications.

2. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing business attire that is clean and pressed. You should also avoid wearing excessive jewelry or makeup.

3. Be Punctual

Punctuality is important for any interview, but it is especially important for a job that requires precision and attention to detail. Make sure you arrive at your interview on time, or even a few minutes early.

4. Be Enthusiastic and Positive

Hiring managers are looking for candidates who are enthusiastic about the job and have a positive attitude. Make sure you convey your enthusiasm during your interview by making eye contact, smiling, and speaking clearly. You should also be prepared to answer questions about why you are interested in the job and what you can bring to the company.

5. Practice Your Answers

Before your interview, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. You should also be prepared to ask the interviewer questions about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Solid Surface Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!