Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Solvent Process Extractor Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

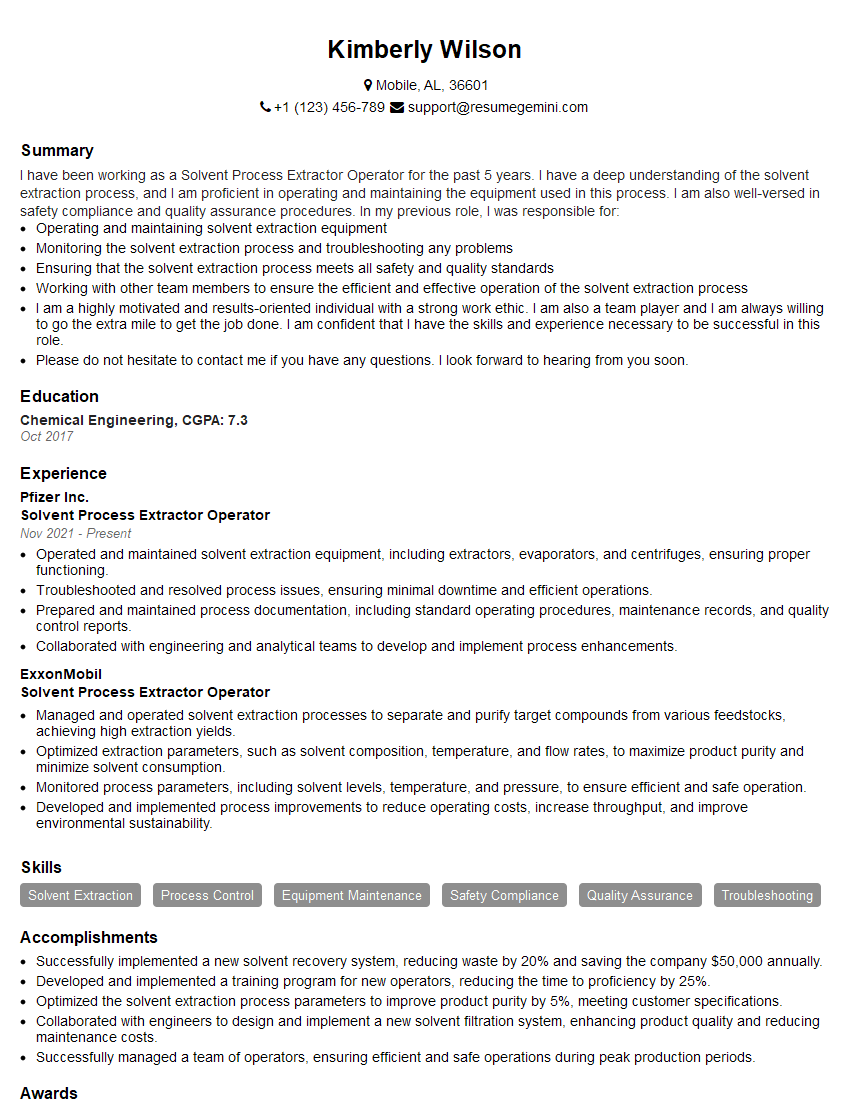

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Solvent Process Extractor Operator

1. Describe the process of solvent extraction in detail.

- Solvent extraction is a separation process that uses a solvent to selectively extract one or more components from a mixture.

- The solvent is chosen based on its ability to dissolve the desired components while leaving the other components behind.

- The mixture is then contacted with the solvent, and the desired components are extracted into the solvent.

- The solvent is then separated from the mixture, and the desired components are recovered from the solvent.

2. What are the different types of solvent extraction processes?

Liquid-liquid extraction

- Liquid-liquid extraction is the most common type of solvent extraction.

- In liquid-liquid extraction, the mixture is a liquid, and the solvent is also a liquid.

- The two liquids are immiscible, meaning that they do not mix together.

Solid-liquid extraction

- Solid-liquid extraction is used to extract components from a solid mixture.

- In solid-liquid extraction, the mixture is a solid, and the solvent is a liquid.

- The solvent is chosen based on its ability to dissolve the desired components from the solid.

3. What are the factors that affect the efficiency of solvent extraction?

- The choice of solvent

- The temperature of the extraction

- The contact time between the mixture and the solvent

- The ratio of the solvent to the mixture

4. What are the advantages and disadvantages of solvent extraction?

Advantages

- Solvent extraction is a very efficient way to separate components from a mixture.

- Solvent extraction can be used to separate components that are difficult or impossible to separate by other methods.

- Solvent extraction is a relatively inexpensive process.

Disadvantages

- Solvent extraction can be dangerous if the solvent is flammable or toxic.

- Solvent extraction can generate waste products that need to be disposed of properly.

5. What are the safety precautions that need to be taken when working with solvents?

- Always wear appropriate personal protective equipment, such as gloves, eye protection, and a respirator.

- Work in a well-ventilated area.

- Do not smoke or eat in the work area.

- Keep solvents away from heat and open flames.

- Store solvents in a safe and secure location.

6. What are the different types of solvents that are used in solvent extraction?

- Aliphatic hydrocarbons

- Aromatic hydrocarbons

- Alcohols

- Ketones

- Esters

7. How do you choose the right solvent for a particular extraction process?

- Consider the solubility of the desired components in the solvent.

- Consider the selectivity of the solvent for the desired components.

- Consider the physical and chemical properties of the solvent.

- Consider the cost of the solvent.

8. What is the difference between a batch and a continuous solvent extraction process?

Batch solvent extraction

- Batch solvent extraction is a process in which the mixture and the solvent are contacted in a batch reactor.

- The mixture and the solvent are mixed together, and the desired components are extracted into the solvent.

- The solvent is then separated from the mixture, and the desired components are recovered from the solvent.

Continuous solvent extraction

- Continuous solvent extraction is a process in which the mixture and the solvent are contacted in a continuous flow reactor.

- The mixture and the solvent are fed into the reactor, and the desired components are extracted into the solvent.

- The solvent is then separated from the mixture, and the desired components are recovered from the solvent.

9. What are the advantages and disadvantages of batch and continuous solvent extraction processes?

Batch solvent extraction

Advantages

- Batch solvent extraction is a simple and inexpensive process.

- Batch solvent extraction is easy to scale up.

Disadvantages

- Batch solvent extraction is not as efficient as continuous solvent extraction.

- Batch solvent extraction is not as well suited for large-scale operations.

Continuous solvent extraction

Advantages

- Continuous solvent extraction is more efficient than batch solvent extraction.

- Continuous solvent extraction is better suited for large-scale operations.

Disadvantages

- Continuous solvent extraction is more complex and expensive than batch solvent extraction.

- Continuous solvent extraction is not as easy to scale up as batch solvent extraction.

10. What are the different applications of solvent extraction?

- Solvent extraction is used to extract a wide variety of components from a wide variety of mixtures.

- Solvent extraction is used in the food industry, the pharmaceutical industry, the chemical industry, and the environmental industry.

- Some of the specific applications of solvent extraction include:

- Extraction of oil from seeds

- Extraction of flavors and fragrances from plants

- Extraction of pharmaceuticals from natural products

- Extraction of metals from ores

- Extraction of pollutants from water and soil

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Solvent Process Extractor Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Solvent Process Extractor Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Solvent Process Extractor Operators are responsible for the safe and efficient operation of solvent extraction equipment in a variety of industries, including food processing, pharmaceuticals, and chemicals. Their key job responsibilities include:

1. Equipment Operation

Operate and maintain solvent extraction equipment, including extractors, evaporators, and other related equipment.

- Monitor and control extraction parameters, such as temperature, pressure, and solvent flow rates.

- Troubleshoot and resolve equipment malfunctions.

2. Solvent Management

Manage and control the use of solvents, including storage, handling, and disposal.

- Maintain accurate records of solvent usage and disposal.

- Comply with all applicable safety and environmental regulations.

3. Product Quality Control

Monitor and maintain product quality standards.

- Collect and analyze product samples.

- Adjust process parameters to meet product specifications.

4. Safety and Maintenance

Follow all safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips for Solvent Process Extractor Operators

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Familiarizing yourself with the company and the specific position you’re applying for will give you a better understanding of the role and the company’s culture. This knowledge will also allow you to tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn more about their mission, values, and products/services.

- Read industry news and articles to stay up-to-date on the latest trends and developments.

2. Practice Your Answers

Preparing your answers to common interview questions will help you feel more confident and articulate during the interview. Consider using the STAR method to structure your answers:

- Situation: Briefly describe the situation or task you were faced with.

- Task: State the specific task or responsibility you were responsible for.

- Action: Outline the specific actions you took to complete the task.

- Result: Describe the positive outcomes or results of your actions.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your relevant skills and experience. Quantify your accomplishments whenever possible to provide concrete evidence of your abilities. For example, instead of saying “I operated solvent extraction equipment,” you could say “I operated solvent extraction equipment for five years, resulting in a 15% increase in product yield.”

- Review the job description and identify the key skills and qualifications required.

- Prepare specific examples from your previous work experience that demonstrate your proficiency in these areas.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- “What are the biggest challenges facing the company right now?”

- “What are the opportunities for professional development within the company?”

5. Follow Up

After the interview, be sure to send a thank-you note to the interviewer within 24 hours. In your note, reiterate your interest in the position and thank the interviewer for their time.

- Restate your key qualifications and how they align with the job requirements.

- Express your enthusiasm for the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Solvent Process Extractor Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!