Are you gearing up for an interview for a Spar Finisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Spar Finisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

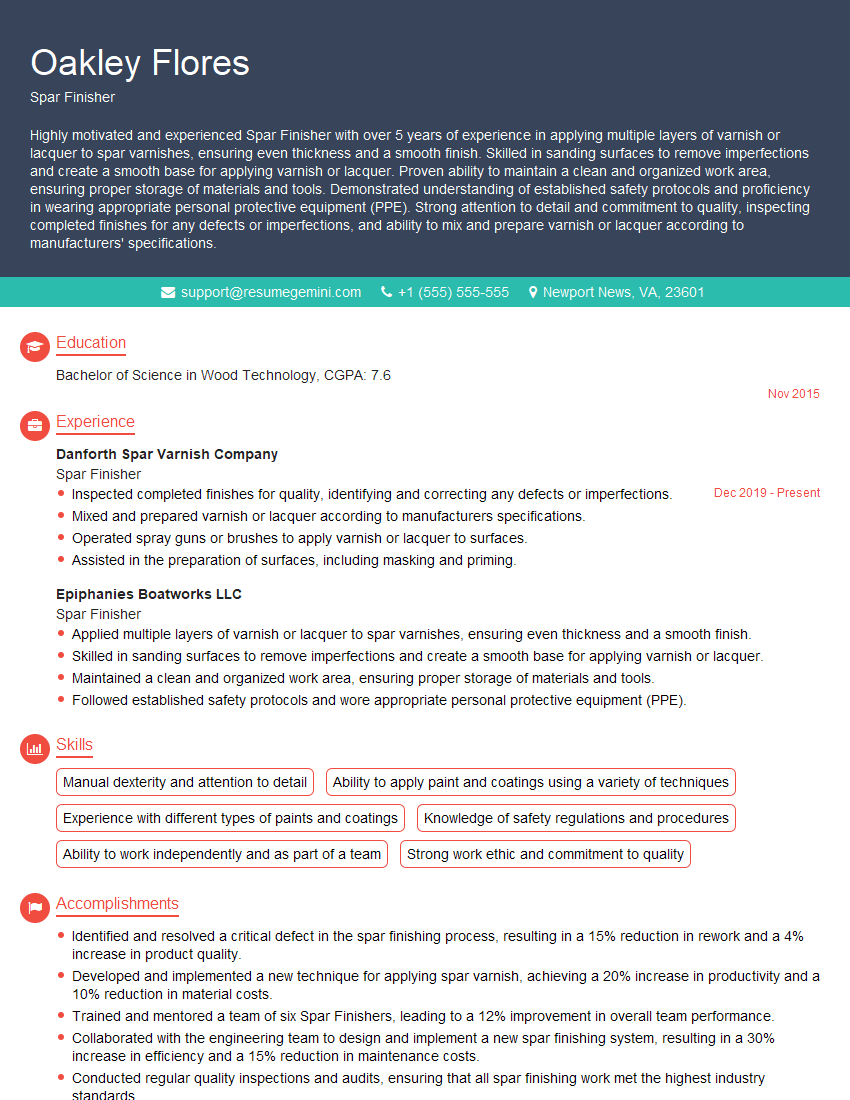

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spar Finisher

1. Describe the key responsibilities of a Spar Finisher in a shipyard?

As a Spar Finisher, my responsibilities include:

- Preparing and finishing spars, masts, and other metal components for marine vessels.

- Using specialized tools and techniques to apply protective coatings, such as paint, epoxy, and galvanizing.

- Ensuring that all finished surfaces meet specified standards for quality and durability.

- Adhering to safety regulations and maintaining a clean and organized work area.

- Collaborating with other tradespeople to complete projects on time and within budget.

2. What are the different types of coatings used in Spar Finishing, and how do you determine the appropriate coating for a specific application?

Coating Types:

- Paint: Used for aesthetic and protective purposes.

- Epoxy: Provides superior corrosion resistance and durability.

- Galvanizing: Hot-dip process that applies a protective zinc layer to steel surfaces.

Coating Selection:

- Consider the material of the substrate (e.g., steel, aluminum).

- Determine the desired level of protection (e.g., corrosion resistance, UV resistance).

- Consult with manufacturers’ specifications and industry standards.

3. Describe the process of preparing a surface for coating, including the different methods used for cleaning, degreasing, and abrading?

- Cleaning: Remove dirt, debris, and contaminants using solvents or detergents.

- Degreasing: Remove oils and grease using chemical degreasers.

- Abrading: Roughen the surface to enhance coating adhesion using sandblasting, grinding, or wire brushing.

4. What are the safety precautions that must be taken when working with coatings and solvents?

- Wear appropriate personal protective equipment (PPE) such as respirators, gloves, and safety glasses.

- Ensure adequate ventilation and avoid breathing in fumes.

- Handle and store chemicals properly according to MSDS guidelines.

- Follow established protocols for mixing and applying coatings.

5. How do you ensure the quality of your workmanship and meet the required standards?

- Adhere to established quality control procedures and industry best practices.

- Thoroughly inspect surfaces before and after coating to identify any defects.

- Use calibrated measuring instruments and follow specified coating thicknesses.

- Obtain feedback from clients and supervisors to continuously improve quality.

6. How do you stay up-to-date on the latest techniques and materials used in Spar Finishing?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Consult with manufacturers’ representatives for product updates.

- Network with other professionals in the field.

7. Describe a challenging project you worked on and how you overcame the obstacles to complete it successfully?

- Provide a specific example of a complex or challenging spar finishing project.

- Explain the obstacles encountered and how you developed innovative solutions.

- Highlight your problem-solving skills, adaptability, and ability to work under pressure.

8. How do you prioritize multiple projects and manage your time effectively?

- Use a to-do list or project management software to keep track of tasks.

- Set realistic deadlines and break down large projects into smaller, manageable chunks.

- Delegate tasks to team members when appropriate.

- Communicate regularly with colleagues and supervisors to ensure timely completion.

9. What are your strengths and weaknesses as a Spar Finisher?

Strengths:

- Attention to detail and precision in workmanship.

- Strong knowledge of coatings and surface preparation techniques.

- Ability to work independently and as part of a team.

Weaknesses:

- Limited experience with advanced automated coating systems.

- Working in confined spaces can be physically demanding at times.

10. Why are you interested in working for our shipyard, and what do you believe you can contribute to our team?

- Express enthusiasm for the shipyard’s reputation and expertise.

- Highlight your skills and experience that align with the company’s needs.

- Demonstrate a willingness to contribute and learn from the team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spar Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spar Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Spar Finisher

Spar Finishers play a crucial role in the manufacturing process by applying the final coating to various surfaces, ensuring a smooth and aesthetically pleasing finish.

1. Surface Preparation

Begin by meticulously preparing the surface to be coated, removing any imperfections and contaminants that could compromise the final finish.

- Sanding and smoothing surfaces to create a uniform texture

- Cleaning surfaces to remove dirt, dust, or debris

2. Coating Application

Apply protective or decorative coatings to enhance the surface’s appearance and durability, ensuring even and consistent coverage.

- Use various application techniques such as spraying, brushing, or rolling

- Monitor coating thickness and adhere to specified requirements

3. Finishing Processes

Perform specialized finishing techniques to achieve the desired surface characteristics, such as gloss, matte, or textured finishes.

- Employ sanding, polishing, or buffing techniques to enhance surface smoothness

- Apply protective topcoats to increase durability and longevity

4. Inspection and Quality Control

Conduct thorough inspections throughout the finishing process to ensure the final product meets quality standards.

- Identify and correct defects or imperfections

- Maintain accurate records of inspection results

Interview Tips for Spar Finishers

To ace a Spar Finisher interview, it is essential to prepare thoroughly and showcase your skills and knowledge.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This demonstrates your interest and eagerness to contribute.

- Visit the company website and social media pages

- Read industry news and articles to stay updated on advancements

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your experience, skills, and career goals. Practicing beforehand will boost your confidence.

- Example: “Describe your experience with different coating materials and application techniques.”

- Example: “How do you ensure the quality of your finished products?”

3. Showcase Your Attention to Detail

Emphasize your meticulous approach to surface preparation and finishing. Highlight your ability to identify and correct imperfections.

- Provide specific examples of projects where you achieved exceptional surface smoothness or solved quality issues.

- Explain your understanding of different coating materials and their properties.

4. Demonstrate Your Problem-Solving Skills

Spar Finishing often requires troubleshooting and problem-solving. Share instances where you encountered challenges and developed effective solutions.

- Example: “Describe a situation where you encountered a coating defect and the steps you took to rectify it.”

- Example: “Explain how you troubleshoot common problems with spray equipment or coating materials.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spar Finisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.