Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Special Equipment Sewing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

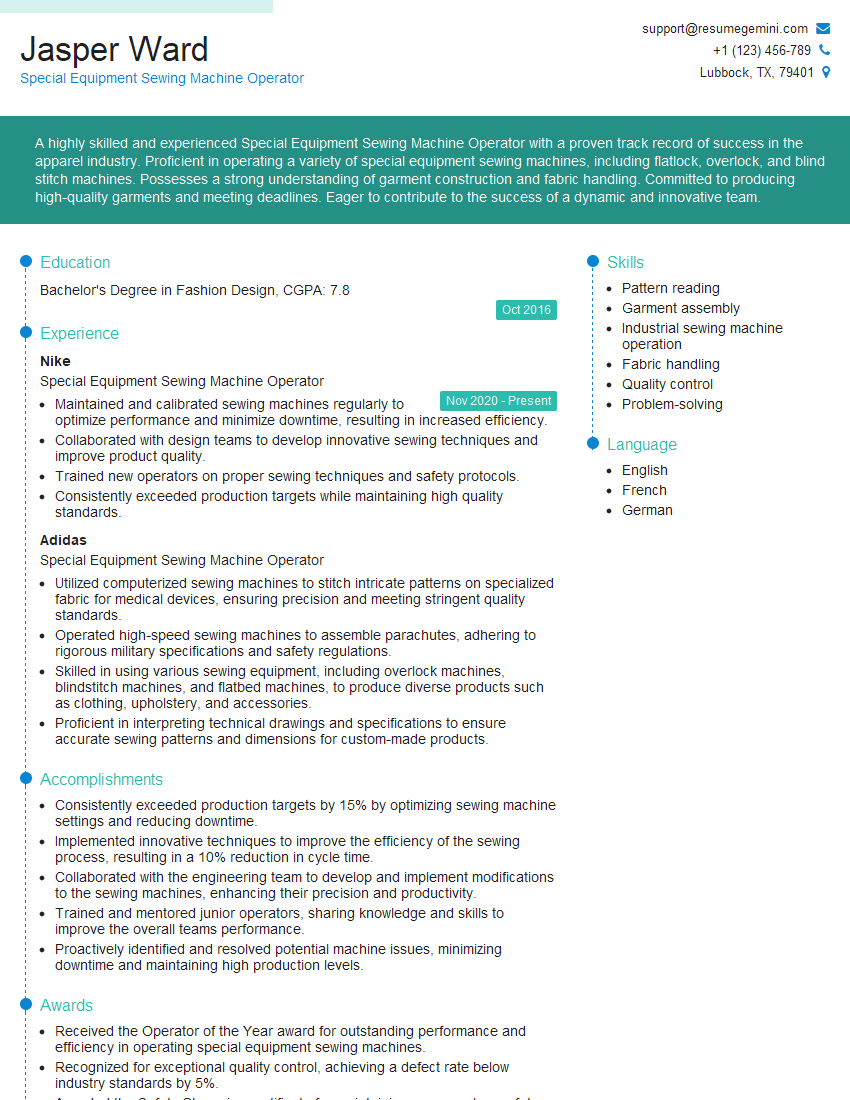

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Special Equipment Sewing Machine Operator

1. What special equipment sewing machines have you worked with in the past? Describe their capabilities and how you used them to produce high-quality products.

- List the specific types of special equipment sewing machines you have operated, such as embroidery machines, quilting machines, or pattern sewing machines.

- Describe the capabilities of each machine, including the types of stitches, patterns, and materials it can handle.

- Explain how you used these machines to produce high-quality products, such as garments, home décor, or industrial products.

2. Describe your experience in setting up and calibrating special equipment sewing machines. How do you ensure that the machines are operating optimally?

: Setup and calibration

- Explain the steps involved in setting up and calibrating special equipment sewing machines, such as installing needles, threading the machine, and adjusting tension settings.

- Describe the tools and techniques you use to calibrate the machines, such as tension gauges and stitch length gauges.

Subheading: Maintenance and troubleshooting

- Explain how you perform routine maintenance on special equipment sewing machines, such as cleaning and lubricating the machine.

- Describe your approach to troubleshooting and repairing common machine problems, such as thread breaks, tension issues, or skipped stitches.

3. How do you ensure that you are producing high-quality products that meet customer specifications? Describe your quality control process.

- Explain the quality control process you follow, including regular inspections and measurements.

- Describe the tools and techniques you use to measure and evaluate product quality, such as rulers, calipers, or sewing gauges.

- Explain how you document and track quality control data to ensure consistency and improve processes.

4. How do you stay up-to-date with the latest advancements in special equipment sewing technology?

- Describe your methods for staying informed about new technologies, such as attending industry events, reading trade publications, or participating in online forums.

- Explain how you evaluate and incorporate new technologies into your work to improve efficiency and product quality.

5. What safety precautions do you take when operating special equipment sewing machines?

- Describe the safety protocols you follow, such as wearing appropriate safety gear, keeping the work area clean and organized, and following lockout/tagout procedures.

- Explain how you identify and assess potential hazards associated with operating special equipment sewing machines.

6. How do you prioritize tasks and manage your time when working in a fast-paced production environment?

- Describe your strategies for prioritizing tasks based on urgency and importance, such as using a to-do list or a scheduling tool.

- Explain how you allocate your time effectively to meet production deadlines while maintaining quality.

7. How do you handle working as part of a team in a production environment?

- Describe your experience working with colleagues to achieve production goals, such as sharing knowledge, assisting with tasks, and providing feedback.

- Explain how you communicate effectively with team members to resolve issues and coordinate work.

8. How do you adapt to changes in production schedules or requirements?

- Describe your flexibility and adaptability in responding to changes in production schedules, such as adjusting your work hours or taking on additional tasks.

- Explain how you remain productive and maintain quality even when faced with unexpected changes.

9. Describe your experience in using computer-aided design (CAD) software for pattern creation or modification.

- Describe the CAD software you have used, such as Lectra, Gerber, or OptiTex.

- Explain how you use CAD software to create or modify patterns, including using digitizing tools, creating grading rules, and generating markers.

10. How do you keep track of your work and ensure that you are meeting production targets?

- Describe the methods you use to track your progress, such as using production logs, spreadsheets, or visual aids.

- Explain how you analyze your data to identify areas for improvement and increase efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Special Equipment Sewing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Special Equipment Sewing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Special Equipment Sewing Machine Operators are responsible for operating and maintaining specialized sewing machines to create a variety of products. Their duties may include:

1. Machine Operation

Skilled operation of specialized sewing machines, such as automated, programmable, or high-speed machines.

- Ensuring proper machine setup, including thread tension, stitch length, and presser foot settings.

- Monitoring machine operation and making adjustments as needed to maintain optimal performance.

2. Material Handling

Handling a variety of materials, including fabrics, leather, and vinyl, with precision.

- Loading and unloading materials onto the machine.

- Inspecting materials for defects and ensuring proper alignment before sewing.

3. Quality Control

Maintaining high quality standards by inspecting finished products for defects.

- Checking seams, stitching, and overall appearance for accuracy and adherence to specifications.

- Identifying and correcting any errors or defects to ensure product quality.

4. Maintenance and Troubleshooting

Performing routine maintenance and troubleshooting tasks on specialized sewing machines.

- Cleaning and lubricating machines to prevent malfunctions.

- Diagnosing and resolving minor mechanical issues, such as thread breakage or tension problems.

Interview Tips

Preparing for an interview for a Special Equipment Sewing Machine Operator position can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company, its products, and the specific requirements of the position. This will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company’s website and social media pages to gather information about their culture and values.

- Review the job description thoroughly to understand the key responsibilities and qualifications.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions. Practice articulating your skills, experience, and reasons for wanting the job.

- For example, you could practice answering questions about your expertise in operating specialized sewing machines or your attention to detail in quality control.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience during the interview. Quantify your accomplishments whenever possible to demonstrate your impact.

- Provide specific examples of your ability to operate specialized sewing machines efficiently and produce high-quality products.

- Highlight your experience in troubleshooting and resolving machine issues, maintaining a clean and organized work area, and meeting production targets.

4. Be Enthusiastic and Professional

Convey your enthusiasm for the position and the industry. Maintain a positive and professional demeanor throughout the interview.

- Smile, make eye contact, and dress appropriately for the occasion.

- Ask thoughtful questions to show your engagement and interest in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Special Equipment Sewing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!