Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Special Machine Stitcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

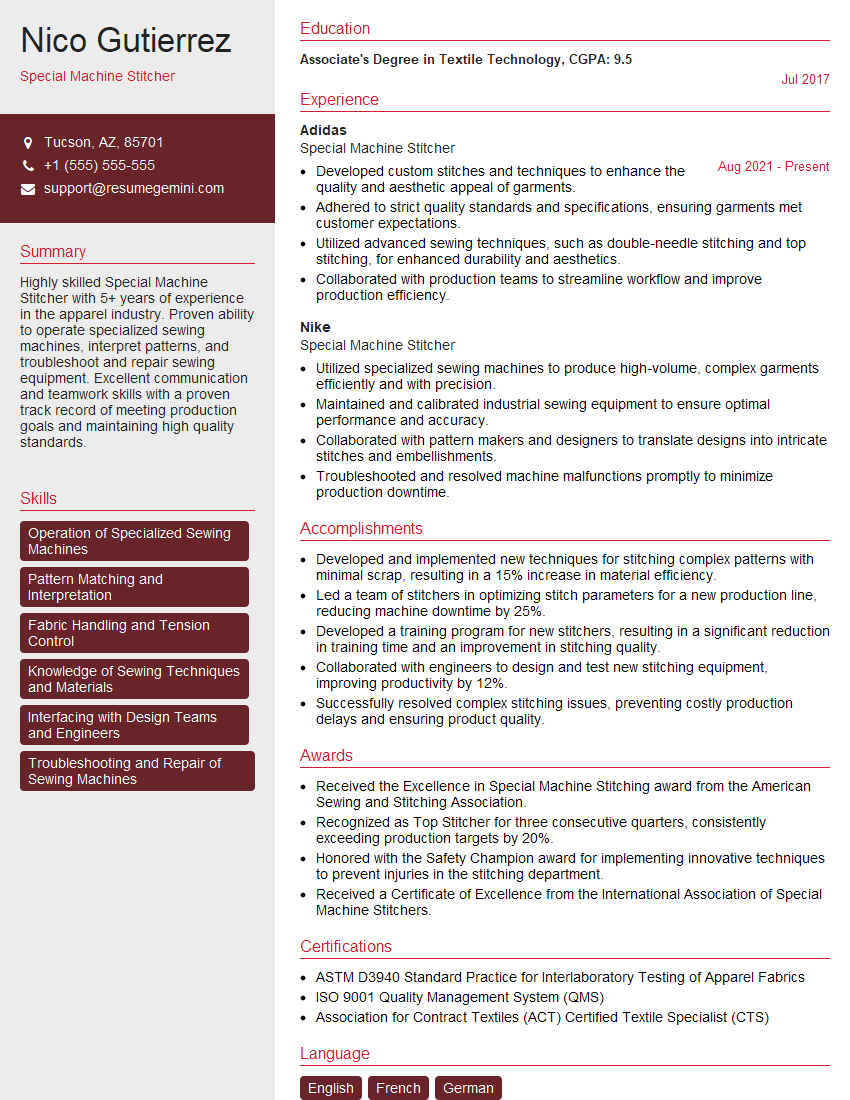

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Special Machine Stitcher

1. Describe the different types of special machines used in stitching operations?

There are various types of specialized machines used in stitching operations, including:

- Buttonhole stitching machines: These machines create reinforced buttonholes in fabrics.

- Bartacking machines: Used to create strong, cross-stitched reinforcements at stress points.

- Blind stitch machines: Stitch fabrics from the underside, creating hidden seams.

- Flatlock machines: Create durable, decorative seams with interlocking stitches.

- Embroidery machines: Programmed to stitch intricate designs onto fabrics.

2. Explain the importance of thread tension in special machine stitching?

Thread Tension and Stitch Quality

- Proper thread tension is crucial for optimal stitch quality.

- Too low tension can result in loose, weak stitches.

- Too high tension can cause thread breakage and puckering.

Adjusting Thread Tension

- Machines typically have adjustable tension dials.

- Tension needs to be fine-tuned based on thread type, fabric thickness, and stitch type.

3. How do you troubleshoot common problems encountered when using special stitching machines?

Common troubleshooting steps for special stitching machines include:

- Skipped stitches: Check thread tension, needle condition, and fabric type.

- Thread breakage: Inspect tension settings, thread quality, and needle damage.

- Puckering: Adjust thread tension or use a different needle size.

- Machine jamming: Clear any fabric or thread buildup, and check for damage.

- Uneven stitches: Ensure proper presser foot pressure and inspect the needle.

4. Describe your experience in using specialized hemming machines?

During my previous role at [Company Name], I operated a variety of specialized hemming machines, including:

- Blind hem machines: Creating invisible hems with a folded edge.

- Rolled hem machines: Rolling and stitching the fabric edge for a decorative finish.

- Flatlock machines: Producing durable, stretchy hems on knit fabrics.

5. How do you ensure stitch quality when using high-speed special stitching machines?

To maintain stitch quality on high-speed special stitching machines, I follow these practices:

- Regular machine maintenance: Keeping machines clean, oiled, and calibrated.

- Optimal thread tension: Adjusting tension to suit thread type and fabric.

- Sharp needles: Using sharp, properly sized needles for each fabric.

- Fabric compatibility: Ensuring that the machine and stitch type are suitable for the fabric.

- Quality control: Regularly inspecting stitch quality and making adjustments as needed.

6. Explain the process of setting up and operating a multi-needle special stitching machine?

Setup

- Install needles and thread the machine according to the stitch pattern.

- Adjust needle spacing and tension settings.

- Configure stitch length and width parameters.

Operation

- Position the fabric under the presser foot.

- Start the machine and guide the fabric along the stitch line.

- Monitor stitch quality and make adjustments as needed.

7. How do you handle fabric distortion or puckering when working with special machine stitching?

To minimize fabric distortion or puckering:

- Use appropriate thread tension: Adjusting tension prevents puckering and thread breakage.

- Select the right needle size and type: Using the proper needle for the fabric prevents skipped stitches and distortion.

- Ensure proper presser foot pressure: Too much pressure can cause puckering.

- Use stabilizers: Using backing or tear-away stabilizers can help prevent fabric distortion.

- Test on scrap fabric: Always test stitch settings on a scrap piece of fabric before working on the actual garment.

8. What safety precautions do you take when operating special stitching machines?

Essential safety precautions for operating special stitching machines include:

- Wear appropriate safety gear: Safety glasses, gloves, and ear protection.

- Keep work area clean and well-lit: Clear away loose fabric and ensure sufficient lighting.

- Never operate a machine with damaged parts: Report any issues promptly.

- Be aware of moving parts: Keep hands and clothing away from needles and moving mechanisms.

- Follow machine operating instructions: Refer to the manufacturer’s manual for specific safety guidelines.

9. How do you inspect and maintain special stitching machines to ensure optimal performance?

Regular inspections and maintenance are crucial for optimal machine performance:

- Daily inspections: Check for thread breakage, needle damage, and fabric buildup.

- Weekly maintenance: Clean and oil all moving parts, adjust tension settings, and replace needles.

- Monthly maintenance: Perform a thorough inspection, lubricate bearings, and check electrical connections.

- Regular calibration: Ensure accurate stitch length and width settings.

- Training: Receive proper training on machine operation and maintenance practices.

10. Describe a challenging stitching project you have worked on using specialized machines?

In my previous role, I was tasked with creating intricate embroidery designs on a large batch of garments. The project involved:

- Using a multi-needle embroidery machine: With 12 needles and multiple thread colors.

- Digitizing the embroidery design: Converting the artwork into machine-readable instructions.

- Ensuring color accuracy and stitch quality: Matching thread colors and adjusting tension for optimal results.

- Meeting tight production deadlines: Completing the project within the specified timeframe.

The project showcased my technical skills, attention to detail, and ability to work under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Special Machine Stitcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Special Machine Stitcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Special Machine Stitcher is responsible for operating and maintaining specialized machines used in the manufacturing process. They work with a variety of materials and fabrics to create products such as clothing, accessories, and industrial components.

1. Machine Operation

The Special Machine Stitcher must be proficient in operating a variety of specialized machines, such as:

- Sewing machines, including flatbed, cylinder bed, and overlock machines

- Embroidery machines

- Laser cutters and engravers

2. Material Handling

The Special Machine Stitcher must be able to handle and work with a variety of materials, such as:

- Fabrics, including natural and synthetic fibers

- Leather

- Plastics

3. Product Quality

The Special Machine Stitcher is responsible for maintaining the quality of the products they produce. They must be able to identify and correct defects, and ensure that the products meet specifications.

4. Machine Maintenance

The Special Machine Stitcher is responsible for maintaining and cleaning the machines they use. They must be able to perform basic maintenance tasks, such as:

- Lubricating moving parts

- Replacing needles

- Adjusting tension settings

Interview Tips

Preparing for an interview for a Special Machine Stitcher position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, research the company you’re applying to and the specific position you’re interviewing for. Learn about the company’s history, mission, products, and services. Also familiarize yourself with the job description and the key responsibilities of the position.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions beforehand so that you can deliver your responses confidently and concisely.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the position you’re applying for. For example, if you have experience operating a variety of sewing machines, be sure to mention this in your interview. You can also highlight any relevant certifications or training you have.

4. Be Prepared to Talk About Your Work Ethic

Employers are looking for candidates who are hardworking and have a strong work ethic. In your interview, be prepared to talk about your work style and how you handle challenges. You can also provide examples of times when you went above and beyond to complete a project.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Special Machine Stitcher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Special Machine Stitcher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.