Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Specialty Materials Printing Machine Setter/Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

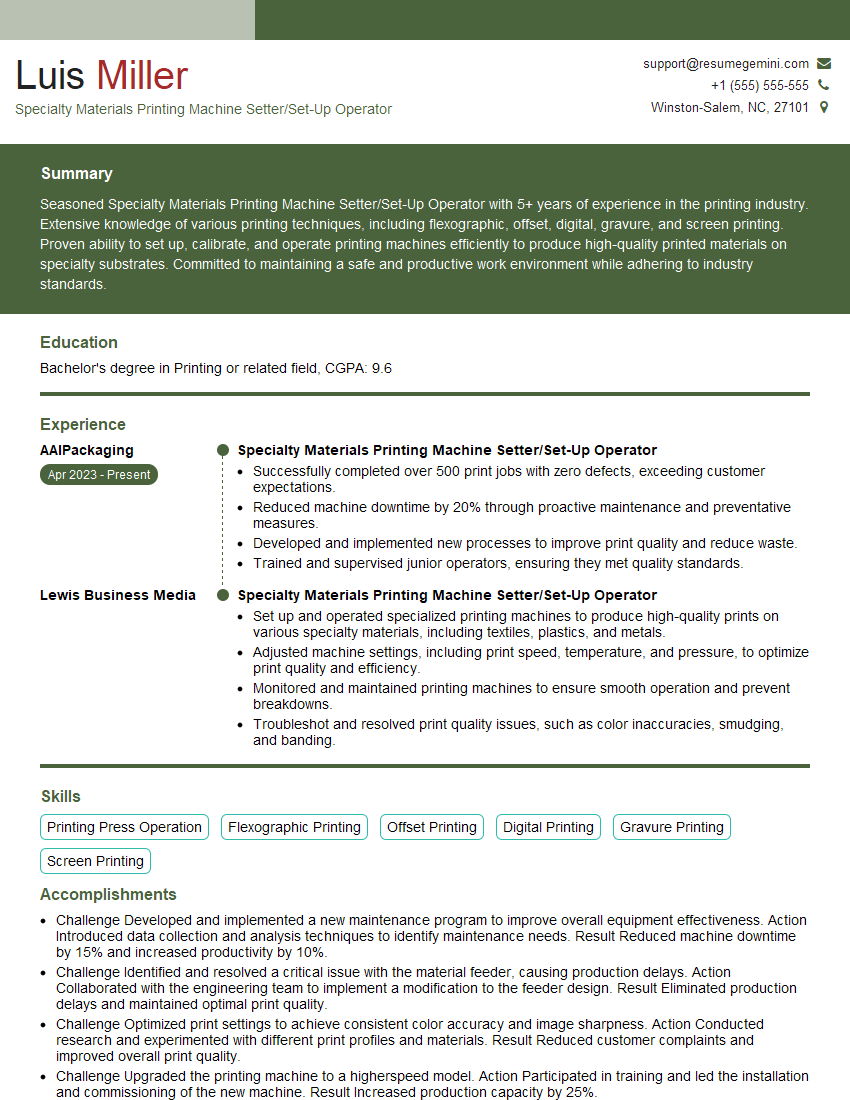

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Specialty Materials Printing Machine Setter/Set-Up Operator

1. What experience do you have with setting up and operating specialty materials printing machines?

I have over 5 years of experience working with specialty materials printing machines, including flexographic, gravure, and digital presses. I have a good understanding of the principles of printing, as well as the different types of materials and inks that can be used. I am also proficient in using a variety of software programs for prepress and postpress operations.

2. What are some of the challenges that you have faced in your previous role as a Specialty Materials Printing Machine Setter/Set-Up Operator?

Time management

- Managing multiple projects and deadlines

- Prioritizing tasks and allocating time effectively

Problem-solving

- Identifying and diagnosing printing issues

- Developing and implementing solutions to ensure print quality

3. How do you ensure that the printing machines are properly calibrated and maintained?

I have a strong understanding of the calibration and maintenance procedures for specialty materials printing machines. I use a variety of tools and techniques to ensure that the machines are operating at peak performance. I also work closely with the maintenance team to keep the machines in good working order.

4. What are some of the safety precautions that you take when operating printing machines?

- Wearing appropriate safety gear, including gloves, safety glasses, and earplugs

- Following all safety protocols and procedures

- Inspecting the machine and work area before starting operations

- Being aware of the potential hazards of the machinery and materials

5. How do you troubleshoot printing issues and ensure that the final product meets the customer’s specifications?

- Analyzing the print quality and identifying the source of the problem

- Making adjustments to the machine settings or using different materials to resolve the issue

- Working with the customer to ensure that the final product meets their expectations

6. What are some of the key skills that you have developed in your previous role that would make you a valuable asset to our team?

- Excellent technical skills in operating and maintaining specialty materials printing machines

- Strong problem-solving and troubleshooting abilities

- Attention to detail and a commitment to quality

- Excellent communication and interpersonal skills

7. What are your career goals for the next 5 years?

I am looking to continue developing my skills and experience in the printing industry. I am particularly interested in learning more about digital printing technologies. I hope to eventually move into a management or supervisory role where I can lead a team of printing professionals.

8. Why are you interested in working for our company?

I am impressed by your company’s reputation for innovation and quality. I believe that my skills and experience would be a valuable asset to your team. I am also excited about the opportunity to work on a variety of challenging projects.

9. What are your salary expectations?

My salary expectations are in line with the industry standard for a Specialty Materials Printing Machine Setter/Set-Up Operator with my level of experience and skills. I am open to discussing compensation and benefits as part of the negotiation process.

10. Do you have any questions for me?

Yes, I would like to know more about the company’s training and development programs. I am also interested in learning more about the company’s sustainability initiatives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Specialty Materials Printing Machine Setter/Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Specialty Materials Printing Machine Setter/Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Specialty Materials Printing Machine Setter/Set-Up Operator is responsible for preparing, adjusting, and monitoring printing machines that specialize in handling unique and challenging materials. Their key responsibilities include the following:

1. Machine Setup and Adjustment

Set up and adjust printing machines according to specified parameters, ensuring optimal performance and quality.

- Calibrate and align printing heads, rollers, and guides.

- Load and install printing materials, including specialty substrates, films, and fabrics.

2. Print Quality Management

Monitor print quality throughout the production run, identifying and resolving issues promptly.

- Inspect printed products for accuracy, color consistency, and defects.

- Adjust machine settings and troubleshoot problems to achieve desired print quality.

3. Material Handling

Handle and store specialty printing materials appropriately to maintain their integrity and prevent damage.

- Unload and handle substrates before and after printing.

- Store materials in controlled environments to ensure quality and prevent deterioration.

4. Process Optimization

Identify and implement process improvements to increase efficiency and reduce production costs.

- Analyze production data to identify bottlenecks and areas for improvement.

- Propose and implement modifications to machine settings and operating procedures.

Interview Tips

To ace an interview for a Specialty Materials Printing Machine Setter/Set-Up Operator position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the printing industry by researching their products, services, and market position. Understanding their specific requirements and challenges will help you tailor your answers and show that you are genuinely interested in the role.

- Visit the company website, read industry publications, and connect with current or former employees on LinkedIn.

- Highlight any knowledge or experience you have with the type of specialty materials used in the company’s printing processes.

2. Emphasize Your Technical Skills

Showcase your expertise in setting up and operating specialty printing machines. Quantify your accomplishments and provide specific examples of how you have solved problems and optimized print quality.

- Describe how you have handled different types of specialty materials, including their unique properties and handling requirements.

- Share your knowledge of printing techniques, such as flexography, gravure, or screen printing, and how you have applied them to achieve desired results.

3. Demonstrate Your Problem-Solving Abilities

Interviewers will be looking for candidates who can identify and resolve issues that may arise during the printing process. Provide examples of how you have handled unexpected challenges, analyzed causes, and implemented effective solutions.

- Describe a situation where you encountered a printing defect and explain how you diagnosed and fixed the problem.

- Discuss how you have collaborated with other team members, such as press operators and quality control inspectors, to resolve complex issues.

4. Highlight Your Attention to Detail

As a Specialty Materials Printing Machine Setter/Set-Up Operator, attention to detail is crucial for ensuring print quality and consistency. Emphasize your ability to inspect printed products thoroughly and identify even minor defects.

- Explain your quality control procedures and how you ensure that printed materials meet the required specifications.

- Provide examples of how you have spotted and prevented potential issues that could have affected print quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Specialty Materials Printing Machine Setter/Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!