Are you gearing up for an interview for a Speeder Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Speeder Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

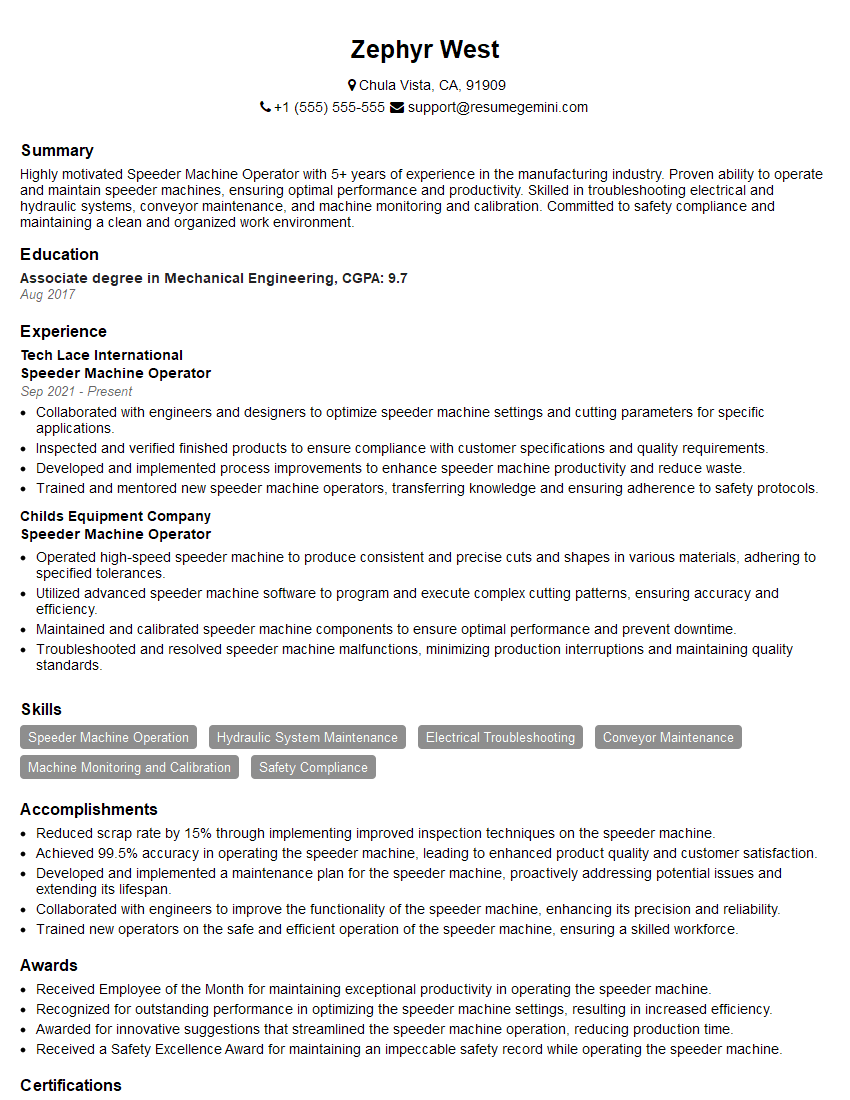

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Speeder Machine Operator

1. If a speeder machine vibrates too much, what do you suspect is causing it?

- Unbalanced rotor

- Misaligned motor

- Worn bearings

- Loose bolts

2. What are the key maintenance procedures for a speeder machine?

Daily

- Check oil levels and add if needed

- Inspect belts and pulleys for wear

- Clean the machine and remove any debris

Weekly

- Lubricate all moving parts

- Check tightness of all bolts

- Inspect electrical connections

Monthly

- Change oil and filter

- Inspect bearings for wear

- Calibrate the machine

3. How do you troubleshoot a speeder machine that is not feeding material correctly?

- Check if the material is properly loaded

- Inspect the feed mechanism for any debris or damage

- Adjust the feed rate if necessary

- Check the motor and power supply

4. What is the safety protocol for operating a speeder machine?

- Wear appropriate PPE, including gloves, safety glasses, and a dust mask

- Make sure the machine is properly grounded

- Do not operate the machine if it is damaged

- Keep hands and loose clothing away from moving parts

- Be aware of potential hazards such as moving belts, sharp edges, and electrical components

5. How do you calculate the production rate of a speeder machine?

Production rate (items/hour) = (Machine speed (items/minute) * 60 minutes/hour) / Cycle time (seconds/item)

6. What is the difference between a single-spindle and a multiple-spindle speeder machine?

- Single-spindle machines have one spindle, while multiple-spindle machines have multiple spindles

- Multiple-spindle machines are more efficient than single-spindle machines because they can produce multiple items at the same time

7. What are the different types of speeder machines?

- Vertical spindle

- Horizontal spindle

- Turntable

- Rotary

8. What is the major advantage of a speeder machine?

- Speed and efficiency

- High precision and accuracy

- Versatility

- Durability

9. What are the limitations of a speeder machine?

- Can only handle smaller workpieces

- Limited speed range

- Can be expensive

10. How would you improve the efficiency of a speeder machine?

- Regular maintenance and calibration

- Use sharp cutting tools

- Optimize feed rates and speeds

- Use automation to reduce manual labor

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Speeder Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Speeder Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Speeder Machine Operators are responsible for the safe and efficient operation of speeder machines, which are used to manufacture textiles and other materials. Their key responsibilities include:

1. Preparing the Machine

Preparing the machine involves checking that it’s in good working order, setting it up with the correct materials, and ensuring that all safety measures are in place before operating it

2. Operating the Machine

Once the machine has been prepared for operation, the speeder machine operator must operate it safely and efficiently. This involves monitoring the machine’s operation, making adjustments as needed, and ensuring that the materials being processed meet the required specifications.

3. Maintaining the Machine

Maintaining the machine involves performing routine maintenance and repairs to keep it in good working order. This may involve cleaning the machine, replacing parts, and making adjustments as needed.

4. Troubleshooting Problems

If the machine encounters any problems, the speeder machine operator must be able to troubleshoot the problem and make repairs as needed. This may involve identifying the cause of the problem and implementing the appropriate solution.

5. Ensuring Quality Control

Speeder machine operators must ensure that the materials being produced meet the required quality standards. This may involve inspecting the materials, testing them, and making adjustments to the machine as needed.

Interview Tips

Preparing for an interview for a Speeder Machine Operator position requires thorough research and practice. Here are some tips to help you ace your interview:

1. Research the Company and Role

Before the interview, take the time to learn about the company and the specific role you’re applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities and requirements of the speeder machine operator position.

2. Practice Answering Common Interview Questions

There are several common interview questions that you’re likely to encounter during an interview for a speeder machine operator position. Some examples include:

- Tell me about your experience operating speeder machines.

- What are your strengths and weaknesses as a speeder machine operator?

- How do you ensure that the materials produced by the speeder machine meet quality standards?

- What are some of the challenges you’ve faced as a speeder machine operator and how did you overcome them?

By practicing your answers to these and other common interview questions, you can increase your confidence and deliver clear and concise responses during the interview.

3. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the speeder machine operator position. This may include your ability to operate speeder machines safely and efficiently, your knowledge of machine maintenance and repair, and your ability to troubleshoot problems.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Speeder machine operators play a vital role in the manufacturing process, and your passion for your work will be evident to the interviewer.

Next Step:

Now that you’re armed with the knowledge of Speeder Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Speeder Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini