Feeling lost in a sea of interview questions? Landed that dream interview for Spike Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Spike Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

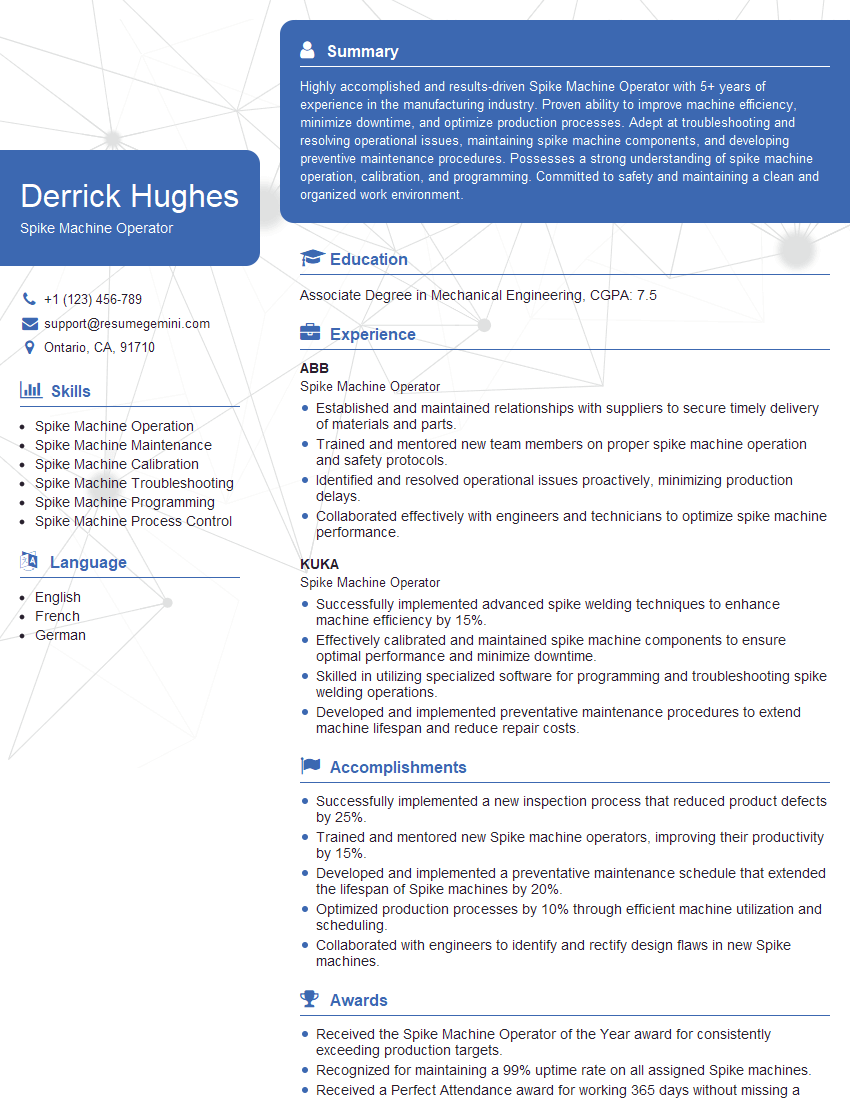

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spike Machine Operator

1. What is a Spike Machine, and what are its primary functions?

A Spike Machine is a specialized device designed for pile driving and extracting operations. Its primary functions include:

- Driving piles into the ground to create foundations for structures

- Extracting piles from the ground when necessary

- Compacting soil or materials using vibration

2. Describe the different types of Spike Machines.

Diesel Spike Machines

- Powered by diesel engines

- Produce high impact force

- Used for heavy-duty pile driving applications

Hydraulic Spike Machines

- Powered by hydraulic systems

- Offer precise control over impact force

- Ideal for sensitive pile driving applications

Electric Spike Machines

- Powered by electric motors

- Environmentally friendly

- Produce low noise and vibration

3. What are the safety precautions that must be observed when operating a Spike Machine?

- Wear appropriate personal protective equipment (PPE) such as hard hat, safety glasses, earplugs, and gloves

- Ensure the machine is in good working condition and properly maintained

- Establish clear communication signals with the crew

- Secure the work area and prevent access to unauthorized personnel

- Follow all manufacturer’s instructions and safety guidelines

4. How do you determine the appropriate pile driving depth and force for a given application?

- Consult with engineers and soil experts to gather data on soil conditions and load requirements

- Conduct soil testing to determine the bearing capacity of the soil

- Use formulas and tables provided by the Spike Machine manufacturer to calculate appropriate depth and force

- Consider the weight and type of structure being supported by the piles

5. Describe the process of extracting piles using a Spike Machine.

The process of extracting piles using a Spike Machine involves:

- Positioning the Spike Machine over the pile to be extracted

- Attaching a specialized extraction head to the pile

- Using the hydraulic system to apply downward pressure on the pile

- Vibrating the pile to loosen it from the soil

- Gradually pulling the pile out of the ground

6. What are the common maintenance tasks required for Spike Machines?

- Regular inspection and lubrication of all moving parts

- Replacement of worn or damaged components

- Checking and maintaining hydraulic fluid levels

- Cleaning and inspecting fuel filters and injectors

- Following manufacturer’s recommended maintenance schedule

7. How do you troubleshoot and repair common Spike Machine malfunctions?

- Identify the symptoms and potential causes of the malfunction

- Refer to manufacturer’s troubleshooting guide and technical manuals

- Use proper tools and techniques to inspect and repair affected components

- Ensure all repairs align with manufacturer’s specifications

- Document and report all repairs and maintenance activities

8. How do you ensure the quality and consistency of your pile driving operations?

- Establish and follow standardized operating procedures

- Monitor and record key performance data such as impact force and penetration depth

- Perform regular inspections and testing of the Spike Machine and pile materials

- Train and certify operators to maintain high levels of skill and knowledge

- Collaborate with engineers and project managers to ensure alignment with specifications

9. Describe your experience in working with different types of soils and soil conditions.

I have experience working with a wide range of soils, including sand, clay, silt, and rocky conditions. I have successfully driven piles in challenging ground conditions, such as soft soils, waterlogged areas, and areas with buried obstacles.

10. How do you stay updated with the latest advancements and best practices in Spike Machine operation?

- Attend industry conferences and workshops

- Read technical journals and articles

- Participate in online forums and discussion groups

- Seek training and certification from manufacturers and professional organizations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spike Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spike Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spike Machine Operators are responsible for the safe and efficient operation of spike machines, which are used to produce metal spikes for a variety of applications. Key responsibilities include:

1. Machine Operation

Spike Machine Operators are responsible for the safe and efficient operation of their equipment at all times. They must be familiar with the safety protocols for the machine and the work area, and they must be able to identify and correct any potential hazards.

- Follow established operating procedures to ensure safe and efficient machine operation.

- Monitor machine performance, including temperature, pressure, and speed, to ensure optimal production.

- Conduct routine maintenance and repairs on the machine, as needed.

2. Material Handling

Spike Machine Operators must be able to handle heavy materials safely and efficiently. They must be able to lift and move heavy coils of wire, and they must be able to feed the wire into the machine without causing any damage. Spike Machine Operators must operate precision equipment with dexterity and accuracy.

- Load and unload wire coils, and maintain a proper supply of materials for production.

- Inspect incoming materials and ensure they meet quality standards.

- Monitor production output and identify any deviations from specifications.

3. Quality Control

Spike Machine Operators must be able to inspect the finished products to ensure that they meet quality standards. They must be able to identify any defects, and they must be able to take corrective action to prevent future defects. Spike Machine Operators must be able to adapt to changing manufacturing conditions

- Conduct quality checks on the finished products to ensure they meet specifications.

- Identify and correct defects in the products, as needed.

- Maintain a clean and organized work area to minimize the risk of contamination.

4. Safety and Environmental Compliance

Spike Machine Operators must be aware of the safety and environmental regulations that apply to their work. They must be able to follow these regulations, and they must be able to identify and correct any potential hazards.

- Follow all safety protocols and procedures to prevent accidents and injuries.

- Maintain a clean and organized work area to minimize the risk of spills or leaks.

- Dispose of waste materials in a safe and environmentally responsible manner.

Interview Tips

To ace the interview for a Spike Machine Operator position, it is important to be prepared. Here are some tips to help you prepare:

1. Research the Company

Before the interview, it is important to learn as much as you can about the company. This will help you to understand the company’s culture, values, and goals. You can research the company’s website, social media pages, and news articles.

- Read about the company’s history, products, and services.

- Learn about the company’s culture and values.

- Identify the company’s goals and objectives.

2. Practice Your Answers

It is also important to practice your answers to common interview questions. This will help you to feel more confident and prepared during the interview. You can practice your answers with a friend or family member, or you can record yourself and listen back to your answers.

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Practice your answers until you are comfortable and confident in your delivery.

- Have a friend or family member listen to your answers and provide feedback.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for the interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also be well-groomed and have a neat appearance.

- Choose clothes that are clean, pressed, and appropriate for a business setting.

- Be well-groomed and have a neat appearance.

- Consider the company’s culture when choosing your outfit.

4. Be Punctual

Punctuality is important for any job interview, but it is especially important for a Spike Machine Operator interview. This shows the interviewer that you are reliable and that you take the interview seriously.

- Plan your route to the interview location in advance.

- Give yourself plenty of time to travel to the interview location.

- Arrive at the interview location at least 10 minutes early.

Additional Tips:

- Be enthusiastic and positive during the interview.

- Ask questions about the position and the company.

- Thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spike Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!