Are you gearing up for an interview for a Spin Table Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Spin Table Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

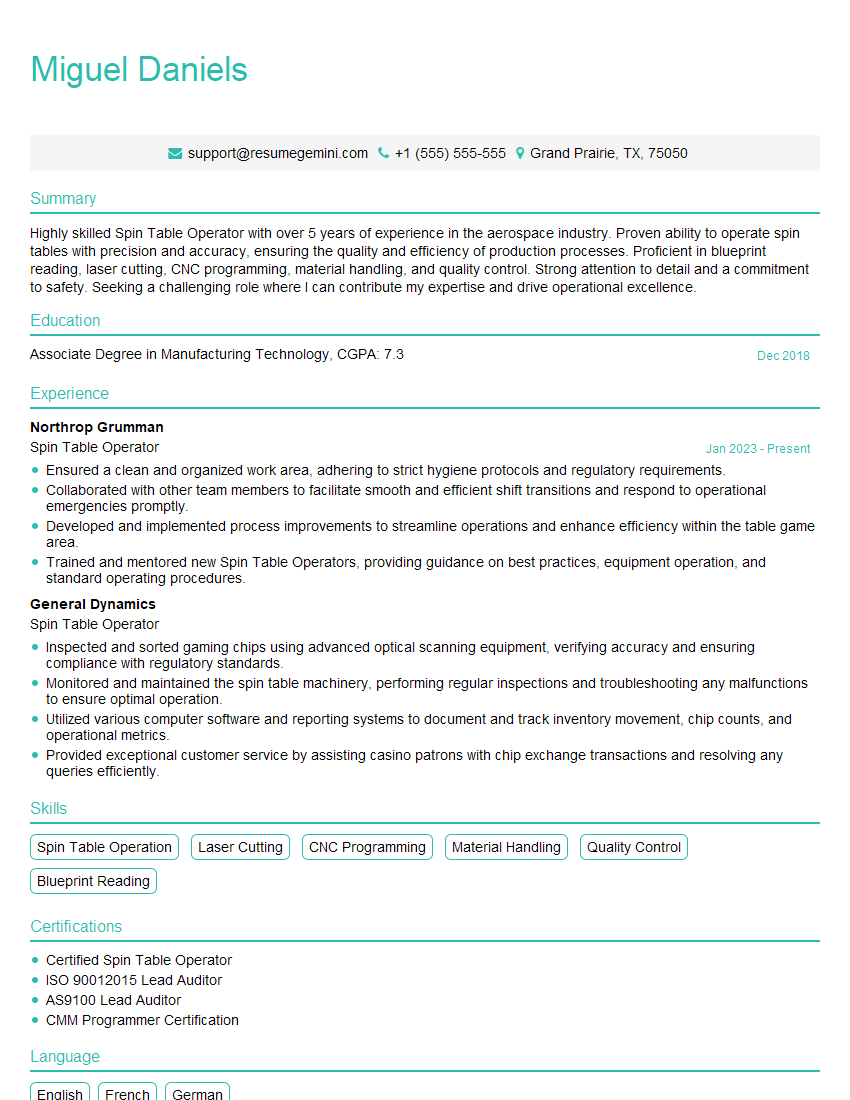

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spin Table Operator

1. What is the primary responsibility of a Spin Table Operator?

- Operate spin tables to spin yarn into threads

- Monitor machines for any irregularities or malfunctions

2. Explain the different types of spin tables used in the textile industry.

Ring Spinning

- Continuous spinning process that produces high-quality yarn

- Employs a ring and traveler to twist and wind the yarn

Open-End Spinning

- Produces yarn without using a ring or traveler

- Fibers are opened and drafted before being twisted and wound onto bobbins

3. What are the key quality control checks performed by Spin Table Operators?

- Yarn count

- Yarn strength

- Yarn evenness

- Visual inspection for defects

4. Describe the process of setting up a spin table for operation.

- Mount the yarn bobbins onto the creel

- Thread the yarn through the spinning guides

- Set the desired yarn count and twist

- Start the spinning process

5. What are the common problems encountered by Spin Table Operators and how do you troubleshoot them?

- Yarn breakage

- Check yarn tension, machine speed, and fiber quality

- Uneven spinning

- Adjust machine settings, clean spinning guides

6. How do you ensure the safety of yourself and others while operating spin tables?

- Wear appropriate safety gear

- Keep the work area clean and free of hazards

- Follow established safety procedures

7. What is the importance of maintaining spin tables regularly?

- Prevents machine malfunctions

- Enhances yarn quality

- Extends the lifespan of the equipment

8. Describe your experience in handling yarn quality issues.

- Identified yarn count variations and adjusted machine settings

- Troubleshooted yarn breakage and uneven spinning

- Worked with quality control team to implement corrective measures

9. How do you stay updated with the latest advancements in spinning technology?

- Attend industry conferences and workshops

- Read trade publications

- Engage with industry professionals

10. Why are you interested in working as a Spin Table Operator in our company?

- Your company’s reputation for producing high-quality textiles

- The opportunity to work with advanced spinning technology

- My passion for the textile industry and my desire to contribute to your team

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spin Table Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spin Table Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Spin Table Operator is responsible for operating a spin table, a specialized machine used in the production of various materials like textiles, paper, and plastics. The operator ensures the proper functioning of the spin table, making sure it produces consistent, high-quality results.

1. Setup and Operation of Spin Table

The operator is responsible for the proper setup and operation of the spin table. This involves setting up the table with the correct parameters, such as speed, temperature, and pressure. The operator monitors the spin table during operation, making adjustments as needed to maintain the desired specifications.

2. Material Handling

The operator handles materials before and after processing on the spin table. This includes loading materials onto the spin table, ensuring they are properly aligned and positioned. After processing, the operator removes the materials from the spin table and inspects them for quality.

3. Quality Control

The operator conducts visual inspections of the processed materials to ensure they meet the required quality standards. The operator identifies and reports any defects or non-conformances to the supervisor.

4. Maintenance and Troubleshooting

The operator performs routine maintenance on the spin table to ensure its proper operation. This includes cleaning, lubrication, and calibration. The operator also troubleshoots and resolves operational issues with the spin table.

Interview Tips

To ace an interview for a Spin Table Operator position, candidates should come prepared and highlight their skills and experience relevant to the job. Here are some interview tips and preparation hacks to help candidates succeed:

1. Research the Company and Industry

Before the interview, candidates should research the company and the industry in which it operates. This demonstrates their interest in the position and shows the interviewer that they have taken the time to learn about the organization. Candidates should also familiarize themselves with the company’s products, services, and market position.

2. Practice Common Interview Questions

Many interview questions are common across different industries and positions. Candidates should prepare for these questions by practicing their answers. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- How do you handle stress and pressure?

- What are your salary expectations?

3. Highlight Relevant Skills and Experience

Candidates should emphasize their skills and experience that are directly relevant to the Spin Table Operator position. This includes experience in operating spin tables, material handling, quality control, and maintenance.

4. Prepare Questions for the Interviewer

At the end of the interview, candidates should prepare insightful questions for the interviewer. This shows that they are engaged and interested in the position. Candidates should ask questions about the company, the position, and the industry.

5. Dress Professionally and Arrive on Time

First impressions matter, so candidates should dress professionally and arrive on time for their interview. This shows the interviewer that they are respectful of the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spin Table Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!