Are you gearing up for an interview for a Spindle Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Spindle Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

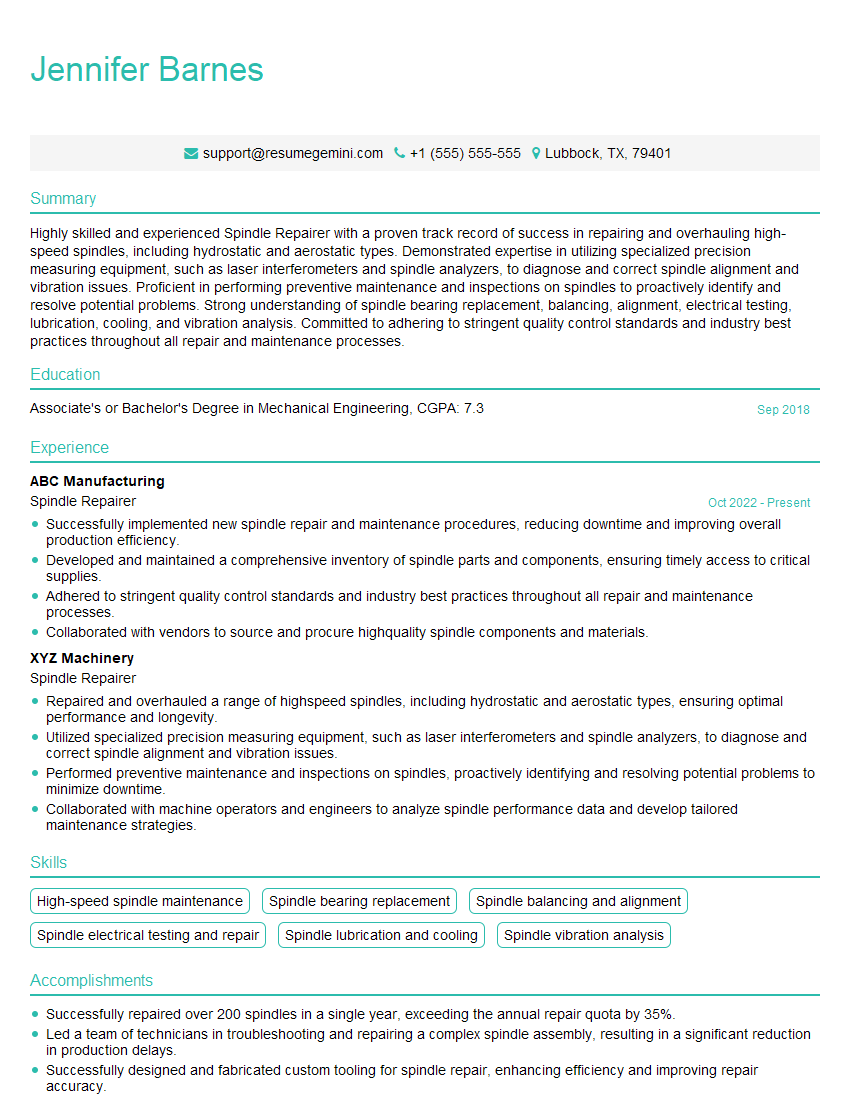

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spindle Repairer

1. Explain the different types of spindle repairs?

- Mechanical repairs: These repairs involve fixing or replacing mechanical components of the spindle, such as bearings, shafts, and gears.

- Electrical repairs: These repairs involve fixing or replacing electrical components of the spindle, such as motors, encoders, and sensors.

- Hydraulic repairs: These repairs involve fixing or replacing hydraulic components of the spindle, such as pumps, valves, and cylinders.

2. What are the common causes of spindle failure?

Bearing failure

- Improper lubrication

- Overloading

- Contamination

Shaft failure

- Fatigue

- Overloading

- Corrosion

Motor failure

- Overheating

- Electrical overload

- Bearing failure

3. What are the steps involved in troubleshooting a spindle problem?

- Gather information about the problem, including the symptoms, the equipment involved, and the operating conditions.

- Inspect the spindle visually for any obvious damage or leaks.

- Perform diagnostic tests to identify the source of the problem.

- Repair or replace the faulty components.

- Test the spindle to ensure that it is functioning properly.

4. What are the safety precautions that should be taken when working on spindles?

- Always wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Never work on a spindle that is powered on.

- Be aware of the dangers of rotating machinery.

- Use proper lifting techniques when handling heavy components.

- Follow all lockout/tagout procedures.

5. What are the different types of spindle bearings?

- Roller bearings: These bearings are designed to handle heavy loads and are commonly used in high-speed applications.

- Ball bearings: These bearings are designed for high-speed applications and are less expensive than roller bearings.

- Hydrostatic bearings: These bearings use a film of oil to support the load and are used in applications where high precision is required.

6. What are the advantages and disadvantages of using hydrostatic bearings?

Advantages

- High precision

- Low friction

- Long life

Disadvantages

- High cost

- Complex design

- Requires a high-pressure oil supply

7. What are the different types of spindle motors?

- AC motors: These motors are powered by alternating current and are commonly used in industrial applications.

- DC motors: These motors are powered by direct current and are used in applications where high torque is required.

- Servo motors: These motors are used in applications where precise control of speed and position is required.

8. What are the advantages and disadvantages of using servo motors?

Advantages

- Precise control of speed and position

- High torque

- Fast response

Disadvantages

- High cost

- Complex design

- Requires a specialized controller

9. What are the different types of spindle encoders?

- Incremental encoders: These encoders provide information about the speed and direction of rotation.

- Absolute encoders: These encoders provide information about the absolute position of the spindle.

- Resolvers: These encoders are used to measure the angle of rotation.

10. What are the advantages and disadvantages of using absolute encoders?

Advantages

- Provide information about the absolute position of the spindle

- High accuracy

- No need for homing

Disadvantages

- More expensive than incremental encoders

- Complex design

- Require a specialized controller

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spindle Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spindle Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Spindle Repairer is responsible for repairing and maintaining spindles and rotating equipment, ensuring they operate efficiently and accurately.

1. Diagnostic and Repair

Analyze spindle malfunctions, diagnose root causes, and execute repairs.

- Identify and replace worn or damaged components, such as bearings, seals, and gears.

- Perform precision alignments and calibrations to ensure accuracy and performance.

2. Overhaul and Maintenance

Conduct routine maintenance and overhauls to extend spindle lifespan and reliability.

- Inspect, clean, and lubricate components to prevent premature failure.

- Monitor spindle performance and identify potential issues before they escalate.

3. Documentation and Reporting

Maintain accurate records of repairs, maintenance, and inspections.

- Document all work performed, including parts replaced and downtime.

- Provide detailed reports on spindle performance and recommendations for improvement.

4. Safety and Compliance

Adhere to safety regulations and industry best practices.

- Use proper tools and equipment safely and effectively.

- Ensure spindles meet regulatory requirements and industry standards.

Interview Tips

Preparing for your Spindle Repairer interview can significantly boost your chances of success. Here are some effective tips:

1. Research the Company and Position

Gather information about the company’s industry, products, and culture. Study the job description thoroughly to understand the specific requirements and expectations.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your technical skills, experience, and problem-solving abilities.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your knowledge of spindle repair techniques, troubleshooting methods, and safety procedures.

3. Emphasize Your Technical Skills

Showcase your proficiency in spindle repair, diagnostic tools, and precision measurement equipment.

- Describe specific projects where you successfully repaired or overhauled spindles.

- Quantify your accomplishments using metrics such as reduced downtime or improved accuracy.

4. Highlight Your Problem-Solving Abilities

Demonstrate your ability to analyze problems, develop solutions, and execute repairs effectively.

- Provide examples of complex spindle malfunctions you have resolved.

- Explain your troubleshooting process and how you identified and fixed the root causes.

5. Prepare Thoughtful Questions

Asking thoughtful questions shows your interest in the position and the company.

- Inquire about the company’s commitment to safety and quality control.

- Ask about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Spindle Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Spindle Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.