Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Spindraw Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Spindraw Operator so you can tailor your answers to impress potential employers.

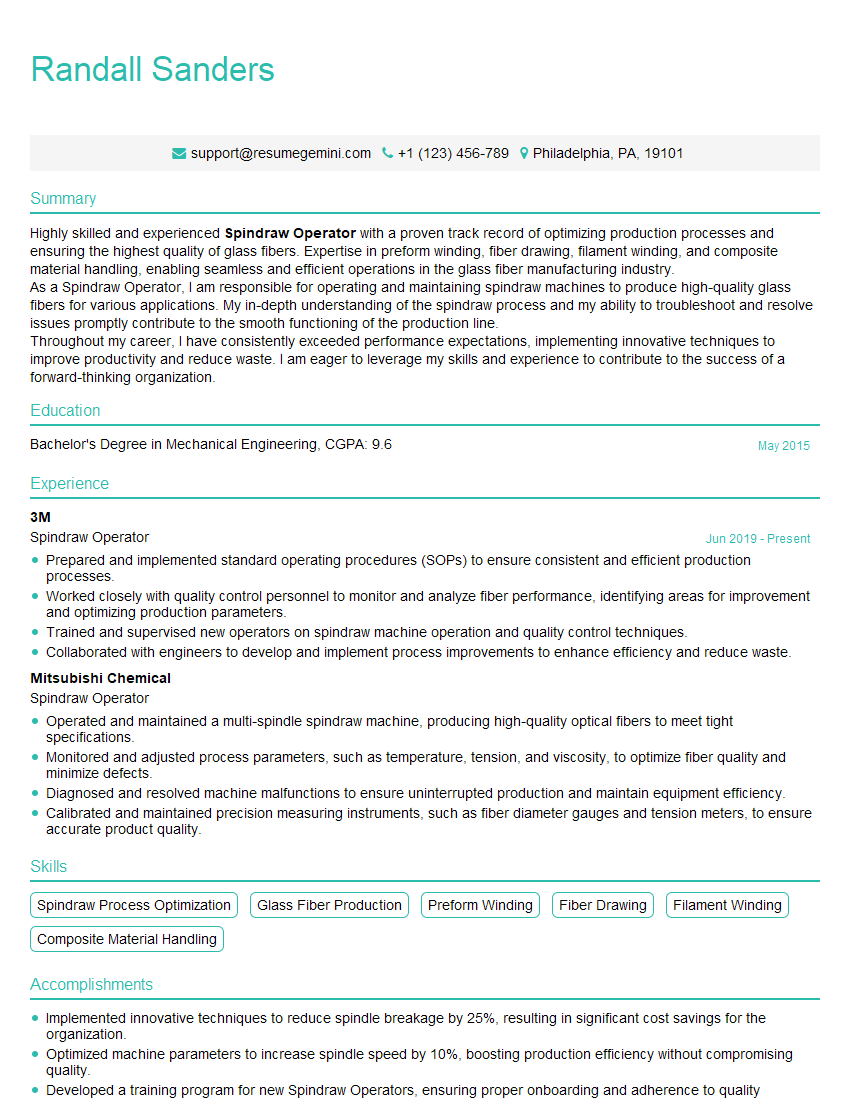

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spindraw Operator

1. Describe the process of spindrawing?

Spindrawing is a specialised manufacturing process used to create intricate and precise tubular components with complex cross-sections. It involves the following steps:

- Preparation: A preform or mandrel is created with the desired cross-sectional shape.

- Spindrawing: The preform is placed in a rotating die and heated to a suitable temperature. As it spins, a high-pressure fluid is forced through the die, expanding the preform and forming it into the final shape.

- Calibration: After spindrawing, the component is calibrated using additional dies to achieve the desired dimensions and tolerances.

- Finishing: The finished component may undergo additional processes such as annealing, machining, or coating.

2. What are the key parameters to monitor during spindrawing?

During spindrawing, the following key parameters are monitored to ensure the quality and accuracy of the process:

- Temperature: The temperature of the preform and die is critical to achieve the desired material flow and prevent defects.

- Pressure: High-pressure fluid is used to expand the preform, and the pressure must be controlled to avoid tearing or bursting.

- Rotation speed: The speed at which the preform rotates affects the uniformity of the expansion and the surface finish.

- Material properties: The material being drawn must have the appropriate properties to withstand the high temperatures and pressures involved.

3. What are the common defects that can occur during spindrawing and how can they be prevented?

Some common defects that can occur during spindrawing include:

- Tearing or bursting: This can be prevented by controlling the fluid pressure and ensuring the material has sufficient strength.

- Non-uniform wall thickness: This can be caused by variations in temperature, pressure, or rotation speed, and can be addressed by optimising process parameters.

- Surface defects: These can arise from impurities in the material or improper lubrication, and can be minimised by maintaining proper die conditions and using appropriate lubricants.

- Dimensional inaccuracies: These can be avoided by calibrating the component after spindrawing using precise dies.

4. Describe the different types of materials that can be drawn using spindrawing?

Spindrawing can be used to draw a variety of materials, including:

- Metals: Steel, aluminium, titanium, copper, and alloys

- Glass: Fused silica, borosilicate

- Ceramics: Alumina, zirconia

- Plastics: Polyethylene, polypropylene, PVC

5. What are the advantages and limitations of spindrawing?

Advantages

- Complex shapes: Spindrawing allows for the creation of intricate tubular components with precise and complex cross-sections.

- Tight tolerances: The process can achieve high dimensional accuracy and tolerances, suitable for demanding applications.

- Mass production: Spindrawing is a relatively fast and efficient process, allowing for the production of large quantities.

Limitations

- Material selection: Not all materials are suitable for spindrawing, and the material properties must be compatible with the process.

- Length limitations: The length of the drawn component is limited by the size of the equipment and the material properties.

6. Explain the role of lubricants in spindrawing?

Lubricants play a crucial role in spindrawing by reducing friction between the preform and the die. They enable smooth material flow, prevent wear on the die, and improve the surface finish of the drawn component. Common lubricants used include graphite, molybdenum disulphide, and various oil-based lubricants.

7. Describe the safety precautions that must be observed during spindrawing?

Spindrawing involves the use of high temperatures and pressures, so proper safety precautions must be followed to minimise risks. These include:

- Protective equipment: Safety glasses, gloves, and appropriate clothing should be worn.

- Machine guarding: The spindrawing machine should have adequate guards and safety interlocks.

- Handling precautions: Hot components and dies should be handled carefully to avoid burns.

- Ventilation: Proper ventilation is essential to remove fumes and vapours generated during the process.

8. What are the maintenance and calibration requirements for spindrawing equipment?

Spindrawing equipment requires regular maintenance and calibration to ensure optimal performance and accuracy. Key maintenance tasks include:

- Die cleaning and inspection: Dies should be cleaned regularly to remove any debris or build-up, and inspected for damage or wear.

- Lubrication: Moving parts and bearings should be lubricated according to the manufacturer’s recommendations.

- Calibration: The equipment should be calibrated regularly using precision measuring instruments to ensure it meets the required tolerances.

9. How do you troubleshoot common issues during spindrawing?

Troubleshooting common issues during spindrawing requires a systematic approach. Some typical issues and their potential solutions include:

- Tearing or bursting: Adjust fluid pressure, check material strength, or modify process parameters.

- Non-uniform wall thickness: Optimise temperature, pressure, and rotation speed, or use specialised dies.

- Surface defects: Improve die conditions, use appropriate lubricants, or consider material impurities.

- Dimensional inaccuracies: Calibrate the equipment, adjust process parameters, or use more precise dies.

10. How do you stay updated with advancements in spindrawing technology?

To stay updated with advancements in spindrawing technology, I engage in the following activities:

- Attend industry conferences and webinars: These events provide insights into the latest research and developments in the field.

- Read technical journals and articles: I subscribe to relevant publications and regularly review articles to stay informed about new techniques and materials.

- Network with experts: I participate in online forums and professional organisations to connect with other spindrawing professionals and exchange knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spindraw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spindraw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spindraw Operators undertake specialized tasks in the manufacturing industry. Their primary responsibility involves operating spindraw machines, which transform plastic into long, continuous fibers used in various applications such as industrial textiles and composites.

1. Machine Operation and Maintenance

Operate spindraw machines, ensuring optimal performance and production targets.

- Monitor equipment parameters, adjusting machine conditions as required.

- Perform routine maintenance and troubleshooting tasks to ensure operational efficiency.

2. Fiber Production and Quality Control

Produce high-quality fibers by following established process parameters.

- Monitor fiber properties consistently, adjusting the draw process to maintain the desired specifications.

- Conduct visual inspections and tests to ensure fiber quality meets established standards.

3. Material Management

Manage raw materials and finished goods to ensure efficient production and inventory control

- Receive, store, and issue raw materials within designated storage areas.

- Inspect incoming materials to ensure that they meet quality standards.

- Pack and label finished products accurately, ensuring proper handling and storage.

4. Safety and Compliance

Maintain a safe and compliant work environment, adhering to established safety protocols and regulations.

- Follow all safety procedures and wear appropriate personal protective equipment (PPE).

- Report potential hazards and incidents promptly, promoting a culture of safety.

Interview Tips

Preparing for a spindraw operator interview requires a combination of technical knowledge, industry understanding, and effective interview skills. Here are some valuable tips to help you ace the interview and showcase your qualifications:

1. Research the Company and Industry

Thoroughly research the company you’re applying to and the industry in which they operate. Understand their products, processes, and market position.

- Visit the company’s website, read industry news, and connect with professionals in the field.

- Prepare questions that demonstrate your knowledge and interest in the company and industry.

2. Quantify Your Experience

When describing your experience, focus on quantifying your accomplishments and providing specific examples. This will help the interviewer understand the tangible results of your work.

- Use numbers and metrics to demonstrate your contributions to fiber production efficiency and quality.

- Highlight any improvements or innovations you implemented that resulted in measurable outcomes.

3. Practice Common Interview Questions

Familiarize yourself with common interview questions and develop thoughtful responses that showcase your skills and experience.

- Prepare answers to questions related to spindraw machine operation, fiber production, and safety procedures.

- Practice answering questions about your work ethic, attention to detail, and problem-solving abilities.

4. Show Enthusiasm and Professionalism

Throughout the interview, maintain a positive attitude and demonstrate your enthusiasm for the role and industry.

- Dress professionally and arrive on time for the interview.

- Ask thoughtful questions that show your engagement and interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Spindraw Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.