Are you gearing up for a career in Spinner Hand? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Spinner Hand and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

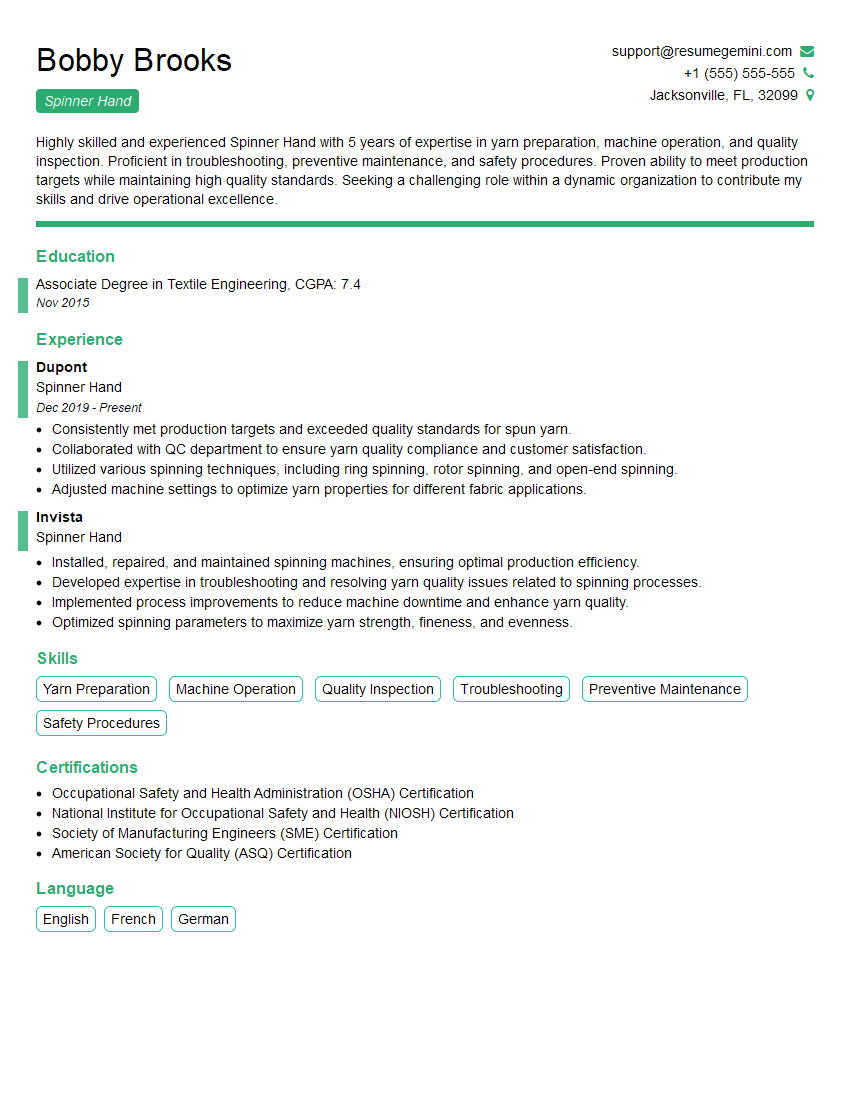

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spinner Hand

1. Describe the different types of spinning methods used in textile manufacturing?

- Ring Spinning: This is the most common method of spinning yarn. It involves drawing out fibers from a roving and twisting them together to form a yarn. The yarn is then wound onto a ring to provide tension.

- Open-End Spinning: In this method, fibers are drawn directly from a bale and fed into a spinning machine. The fibers are then spun together and wound onto a bobbin without the use of a ring.

- Self-Twist Spinning: This method uses a special spinning machine that twists the fibers together by itself. The fibers are fed into the machine and then spun together by a rotating spindle.

2. What are the key factors that affect the quality of the yarn produced by a spinning machine?

Fiber Properties

- Fiber length

- Fiber strength

- Fiber fineness

Spinning Process Parameters

- Spinning speed

- Draft ratio

- Twist level

Machine Condition

- Proper maintenance

- Calibration

- Regular cleaning

3. How do you ensure that the yarn produced meets the desired specifications?

- Regular monitoring of spinning process parameters

- Inspection of yarn samples at regular intervals

- Use of statistical process control (SPC) techniques

- Calibration of spinning machines

- Training of operators

4. What are the common problems that can occur during the spinning process and how do you troubleshoot them?

- Yarn breakage: This can be caused by weak fibers, improper spinning parameters, or machine problems.

- Uneven yarn: This can be caused by variations in fiber properties, spinning parameters, or machine condition.

- Yarn hairiness: This can be caused by excessive fiber breakage or improper spinning parameters.

5. What are the latest advancements in spinning technology that you are aware of?

- Vortex spinning: This is a new spinning technology that uses a vortex to twist fibers together. It can produce yarns with higher strength and lower hairiness.

- Air-jet spinning: This is another new spinning technology that uses an air jet to twist fibers together. It can produce yarns with higher speed and lower energy consumption.

- Compact spinning: This is a spinning technology that uses a special spinning machine to compact the yarn during the spinning process. It can produce yarns with higher strength and lower hairiness.

6. What is the difference between a spinner and a weaver?

- A spinner is responsible for creating yarn from fibers. This involves drawing out fibers from a roving and twisting them together to form a yarn.

- A weaver is responsible for creating fabric from yarn. This involves interlacing two sets of yarn at right angles to each other.

7. What are the different types of weaving machines and what are their advantages and disadvantages?

- Power loom: This is the most common type of weaving machine. It uses a shuttle to carry the weft yarn across the warp yarn.

- Air-jet loom: This type of weaving machine uses an air jet to carry the weft yarn across the warp yarn. It can produce fabric at higher speeds than a power loom.

- Water-jet loom: This type of weaving machine uses a water jet to carry the weft yarn across the warp yarn. It can produce fabric at even higher speeds than an air-jet loom.

8. What are the different types of fabric defects and how do you prevent them?

- Yarn defects: These defects are caused by weak or uneven yarn.

- Weaving defects: These defects are caused by errors in the weaving process, such as broken warp or weft yarns.

- Finishing defects: These defects are caused by improper finishing processes, such as dyeing or printing.

9. How do you ensure that the fabric produced meets the desired specifications?

- Regular monitoring of weaving process parameters

- Inspection of fabric samples at regular intervals

- Use of statistical process control (SPC) techniques

- Calibration of weaving machines

- Training of operators

10. What are the latest advancements in weaving technology that you are aware of?

- 3D weaving: This is a new weaving technology that allows for the creation of three-dimensional fabrics.

- Jacquard weaving: This is a weaving technology that uses a special loom to create intricate patterns in fabric.

- Digital printing: This is a printing technology that uses digital files to create patterns on fabric.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spinner Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spinner Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Spinner Hand is responsible for operating and maintaining spinning machines used in the production of yarn and thread. Their primary duties include:

1. Machine Operation

Setting up and operating spinning machines according to established procedures.

- Monitoring machine performance, making adjustments as needed to ensure optimal operation.

- Troubleshooting and resolving any machine malfunctions or breakdowns.

2. Yarn Quality Control

Inspecting yarn quality and identifying any defects or irregularities.

- Maintaining yarn tension and count within specified tolerances.

- Performing visual inspections to detect broken fibers, unevenness, or other anomalies.

3. Production Monitoring

Maintaining production records and ensuring that targets are met.

- Monitoring machine efficiency and identifying areas for improvement.

- Communicating production issues or delays to supervisors or team members.

4. Machine Maintenance

Performing basic maintenance and cleaning tasks on spinning machines.

- Lubricating and cleaning machine components to minimize wear and tear.

- Replacing worn or damaged parts as needed.

Interview Tips

To ace an interview for a Spinner Hand position, candidates should consider the following preparation tips:

1. Research the Company and Position

Demonstrate your interest and preparation by researching the company’s background, products or services, and the specific requirements of the Spinner Hand role.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating and maintaining spinning machines, as well as your attention to detail and ability to troubleshoot.

3. Quantify Your Accomplishments

Whenever possible, provide specific examples and quantifiable results of your contributions to previous roles, such as reducing machine downtime or improving yarn quality.

4. Practice Common Interview Questions

Prepare answers to common interview questions related to your experience, skills, and motivation for applying for the position.

Example Outline:

- Tell me about your experience operating spinning machines.

- Describe a time when you had to troubleshoot a machine malfunction.

- How do you maintain yarn quality and ensure production targets are met?

- What are your strengths and weaknesses as a Spinner Hand?

5. Dress Professionally and Arrive on Time

Make a good first impression by dressing appropriately for the interview and arriving punctually.

6. Ask Informed Questions

Show your engagement and interest by asking thoughtful questions about the company, the role, or the industry.

7. Follow Up

After the interview, send a thank-you note to the hiring manager, reiterating your interest in the position and expressing your gratitude for the opportunity to interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Spinner Hand role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.