Are you gearing up for an interview for a Spinning Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Spinning Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

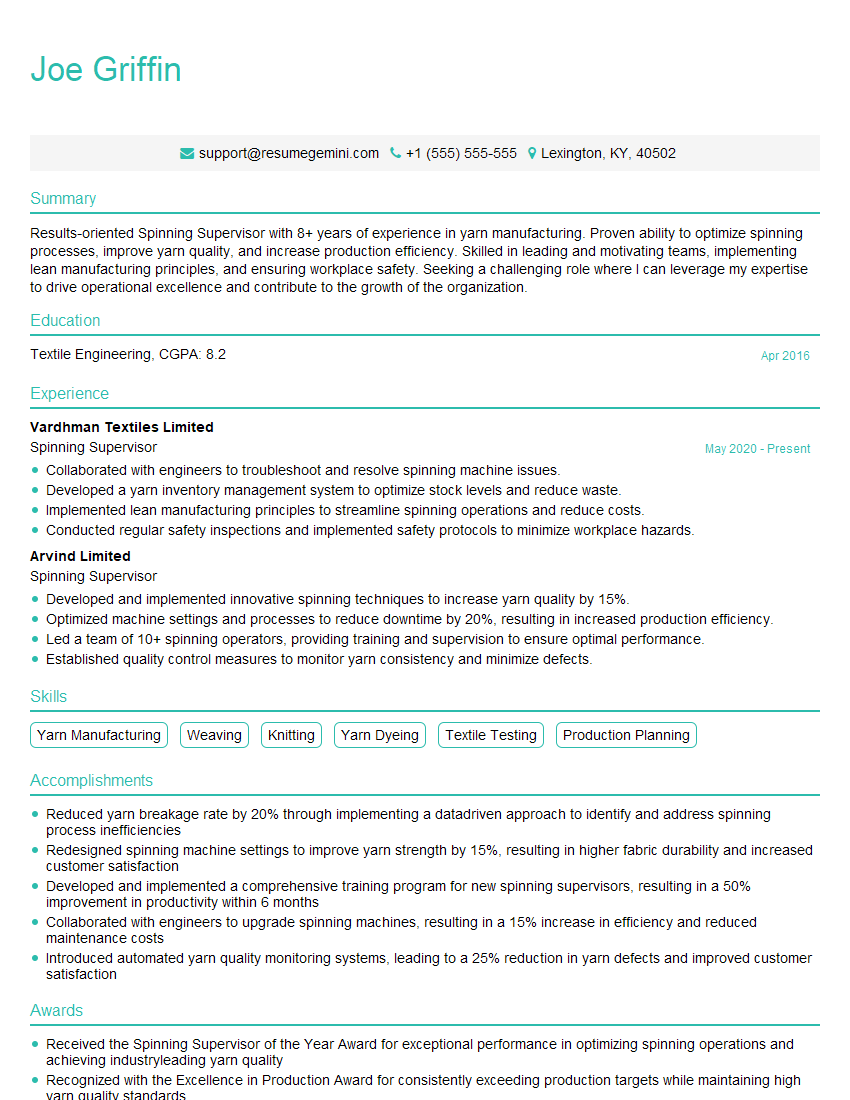

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spinning Supervisor

1. What is your experience with spinning machines, and what type of machines have you worked with?

In my previous role as a Spinning Supervisor at [Company Name], I was responsible for overseeing the operation and maintenance of a wide range of spinning machines, including ring spinning frames, open-end spinning machines, and rotor spinning machines. I have extensive experience in troubleshooting and resolving machine breakdowns, optimizing machine settings to enhance productivity, and implementing preventive maintenance programs to ensure the smooth operation of the spinning process.

2. Describe your approach to optimizing spinning machine productivity.

Maximizing Machine Efficiency

- Regularly monitor and analyze machine performance metrics, such as spindle speed, yarn quality, and energy consumption, to identify areas for improvement.

- Implement modifications to machine settings, including spindle speed, draft ratio, and twist factor, based on data analysis and industry best practices.

Minimizing Downtime

- Conduct thorough preventive maintenance checks to identify potential issues before they escalate into breakdowns.

- Train operators on proper machine operation and maintenance techniques to reduce errors and enhance machine longevity.

3. How do you maintain the quality of yarn produced by the spinning machines?

Maintaining yarn quality is paramount in my role. I implement the following measures:

- Establish and monitor yarn quality parameters, including yarn count, strength, elongation, and evenness.

- Regularly inspect yarn samples to identify defects and trace them back to the source for corrective actions.

- Collaborate with the quality control department to ensure compliance with industry standards and customer specifications.

4. What measures do you take to reduce yarn waste and improve material utilization?

Minimizing yarn waste is essential for cost optimization. I employ the following strategies:

- Optimize spinning machine settings to reduce yarn breakage and improve yarn quality, leading to less waste.

- Implement waste recycling programs to collect and re-spin yarn waste, reducing waste disposal costs.

- Monitor yarn consumption rates and identify areas for improvement in material utilization, such as reducing yarn tension during winding.

5. How do you manage a team of spinning operators and ensure their efficiency and productivity?

Training and Development

- Provide comprehensive training to operators on machine operation, maintenance, and quality control procedures.

- Foster a culture of continuous improvement by encouraging operators to share ideas and participate in skill development programs.

Motivation and Performance Management

- Set clear performance expectations and provide regular feedback to operators on their progress.

- Recognize and reward operators for their contributions and achievements.

Communication and Collaboration

- Maintain open communication channels to address operator concerns and foster a positive work environment.

- Empower operators to make decisions within their scope of responsibility, enhancing their sense of ownership.

6. What are the safety protocols and procedures you implement in the spinning department?

Ensuring the safety of my team is a top priority. I strictly adhere to the following protocols:

- Conduct regular safety inspections of machines and work areas to identify potential hazards.

- Provide comprehensive safety training to operators on machine operation, handling hazardous materials, and emergency response procedures.

- Enforce the use of personal protective equipment, such as earplugs, safety glasses, and protective clothing.

7. How do you stay updated with the latest advancements in spinning technology?

To maintain my technical expertise, I actively engage in the following:

- Attend industry conferences and workshops to learn about new technologies and best practices.

- Subscribe to trade publications and research journals to stay informed about advancements in spinning machinery and processes.

- Collaborate with equipment manufacturers and technical experts to gain insights into emerging technologies.

8. Describe your role in implementing a new spinning machine in the production process.

Planning and Preparation

- Conduct thorough research and evaluation of available spinning machines to identify the optimal solution.

- Collaborate with engineering and production teams to determine machine specifications and installation requirements.

Implementation and Training

- Supervise the installation and commissioning of the new machine.

- Train operators on the operation and maintenance of the new machine, ensuring a smooth transition.

Optimization and Monitoring

- Monitor the performance of the new machine to identify areas for improvement and optimization.

- Make adjustments to machine settings and processes to enhance productivity and yarn quality.

9. How do you adapt to changes in production requirements and customer demands?

In a dynamic production environment, I follow these strategies:

- Stay informed about market trends and customer demands through regular communication with sales and marketing teams.

- Review production schedules and adjust machine settings and operator assignments to meet changing requirements.

- Work closely with the supply chain to ensure timely availability of raw materials and accessories.

10. Describe a time when you faced a challenging situation in the spinning department and how you resolved it.

Challenge

- Experienced a sudden increase in yarn breakage, resulting in reduced productivity and increased waste.

Actions Taken

- Thoroughly inspected the spinning machines to identify the root cause.

- Analyzed yarn samples to determine the nature of the breakage.

- Made adjustments to machine settings, including spindle speed and twist factor.

Resolution

- Identified the issue as a misalignment of the spindles.

- Recalibrated the spindles and implemented a preventive maintenance program to prevent future misalignment.

- Reduced yarn breakage significantly, improving productivity and reducing waste.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spinning Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spinning Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Supervisors in the spinning industry play a pivotal role in ensuring efficient and profitable mill operations. Their primary responsibilities encompass:

1. Production Management

Oversee all aspects of the spinning process to maintain optimal production levels and product quality.

- Set and monitor production targets, ensuring maximum machine utilization.

- Manage spinning machines, including calibration, maintenance, and troubleshooting.

2. Quality Control

Establishing and adhering to quality standards throughout the spinning process.

- Monitor yarn quality, identifying and rectifying defects promptly.

- Conduct regular yarn testing to ensure compliance with specifications.

3. Team Management

Leading and managing a team of operators and technicians.

- Provide training and support to ensure team members possess the necessary skills.

- Motivate and empower team members to maximize productivity.

4. Cost Control

Monitoring and controlling production costs to optimize profitability.

- Analyze production costs and identify areas for improvement.

- Implement cost-effective measures to reduce wastage and increase efficiency.

Interview Tips

Preparing thoroughly for a Spinning Supervisor interview can significantly enhance your chances of success. Here are some indispensable tips to help you ace the interview:

1. Research the Company and Position

Gather as much information as possible about the company and the specific role. This will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company website to learn about their history, values, and products.

- Study the job description carefully to understand the key responsibilities and qualifications.

2. Highlight Relevant Experience and Skills

Tailor your resume and interview answers to showcase your relevant experience and skills. Quantify your accomplishments whenever possible.

- Emphasize your expertise in spinning operations, quality control, and team management.

- Provide specific examples of how you improved production efficiency or reduced costs in previous roles.

3. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview.

- Review questions related to your experience, skills, and knowledge of the spinning industry.

- Consider how you would answer questions about your leadership style, problem-solving abilities, and cost-control strategies.

4. Ask Meaningful Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest and engagement. This is an opportunity to clarify any uncertainties and show that you are eager to learn more about the role and company.

- Ask about the company’s growth plans and industry outlook.

- Inquire about the opportunities for professional development and advancement.

5. Follow Up Professionally

Within 24 hours of the interview, send a brief thank-you note to the interviewer. This is an opportunity to reiterate your interest in the position and thank them for their time.

- Express your appreciation for the opportunity to interview.

- Reiterate your key qualifications and why you are a suitable candidate for the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Spinning Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.