Feeling lost in a sea of interview questions? Landed that dream interview for Spiral Bevel Gear Generator Set-Up Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Spiral Bevel Gear Generator Set-Up Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

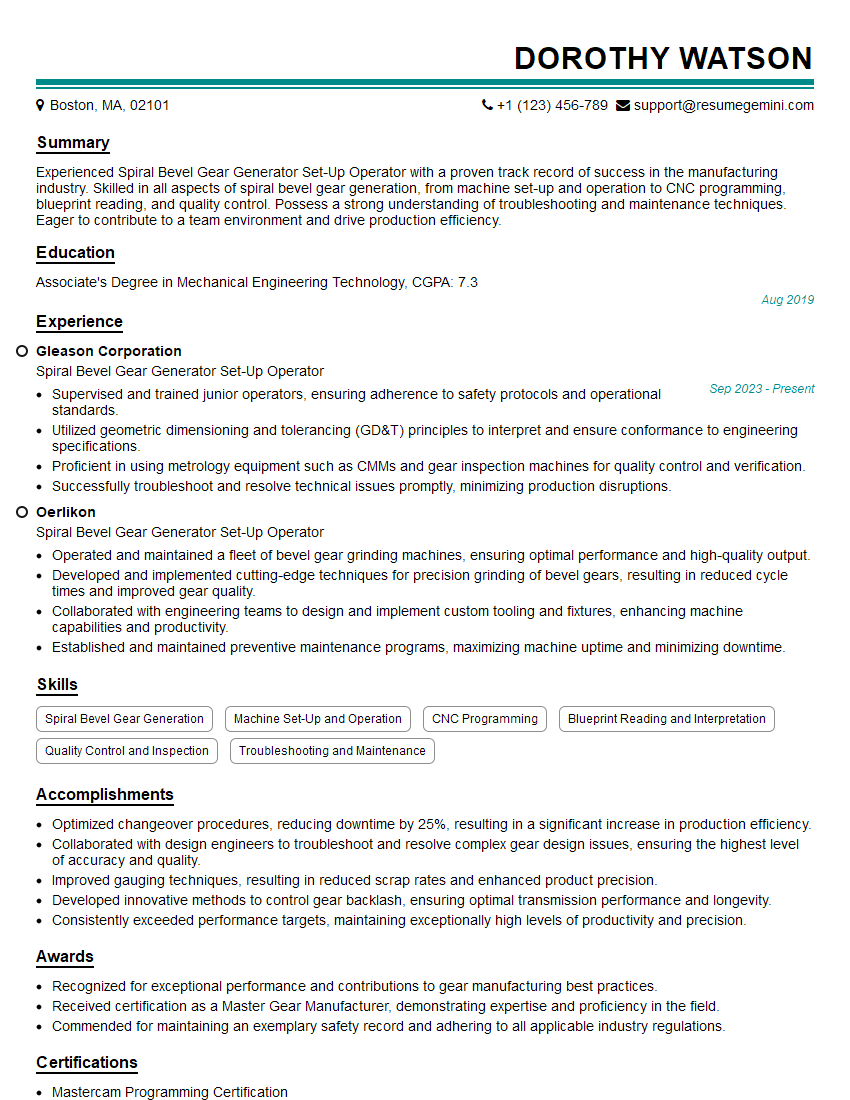

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spiral Bevel Gear Generator Set-Up Operator

1. Describe the process of setting up a spiral bevel gear generator?

1: Pre-Setup Checks

- Verify machine specifications and requirements.

- Inspect the machine and tooling for wear or damage.

- Lubricate and clean the machine.

Subheading 2: Mounting the Blank

- Center and secure the gear blank on the mandrel.

- Adjust the mandrel height to match the machine specifications.

Subheading 3: Setting the Cutter Head

- Install the appropriate cutter head and arbor.

- Align the cutter to the center of the blank.

- Set the cutter depth and angle using a dial indicator.

Subheading 4: Calibrating the Machine

- Enter the required gear parameters into the machine.

- Run a test cut to verify the setup and make any necessary adjustments.

2. How do you ensure accuracy in spiral bevel gear cutting?

- Precisely align the cutter to the center of the blank.

- Use a dial indicator to accurately set the cutter depth and angle.

- Conduct regular inspections of the cutting tools and machine to identify and rectify any inaccuracies.

- Calibrate the machine regularly using certified standards.

- Monitor the cutting process and make adjustments as necessary to maintain accuracy.

3. Explain the importance of lubrication in spiral bevel gear generator operation?

- Reduces friction between moving parts, extending their lifespan.

- Removes metal chips and debris, preventing damage to the machine.

- Improves cutting performance by maintaining the proper temperature of the cutter and workpiece.

- Enhances the surface finish of the gear by preventing galling or scoring.

4. What troubleshooting techniques do you use to resolve common spiral bevel gear generator issues?

- Identify the issue by observing machine behavior and analyzing error messages.

- Check for broken or worn-out parts, such as cutters or bearings.

- Verify the machine settings and ensure they match the gear requirements.

- Calibrate the machine or sensors to ensure accuracy.

- Refer to the manufacturer’s manual or technical support for guidance.

5. Describe your experience with different types of spiral bevel gears and their applications?

- Spur gears: Used in high-speed applications with low torque requirements.

- Helical gears: Used in applications where noise reduction and smooth operation are essential.

- Bevel gears: Used to transmit power between gears with non-parallel axes.

- Hypoid gears: Used in automotive applications to reduce noise and vibration.

- Zerol gears: Used in applications where high strength and low noise are required.

6. How do you maintain and calibrate a spiral bevel gear generator to ensure optimal performance?

- Regularly clean and lubricate the machine to prevent wear and tear.

- Inspect and replace worn-out or damaged parts promptly.

- Calibrate the machine according to the manufacturer’s guidelines.

- Check the accuracy of the machine using certified standards.

- Document maintenance and calibration activities for quality control purposes.

7. Explain how to use a dial indicator to set the cutter depth and angle on a spiral bevel gear generator.

- Mount the dial indicator on a fixture adjacent to the cutter.

- Zero the dial indicator while resting it on the top or bottom of the gear blank.

- Rotate the blank to find the deepest or shallowest point of the gear teeth.

- Adjust the cutter depth until the dial indicator reads the desired value.

- Set the cutter angle by rotating the blank while monitoring the dial indicator reading.

8. What are the potential consequences of incorrect setup or operation of a spiral bevel gear generator?

- Inaccurate gear cutting, leading to poor gear performance.

- Damage to the cutter or workpiece due to excessive force or vibration.

- Premature failure of the gears due to improper lubrication or maintenance.

- Machine downtime and production delays caused by breakdowns or repairs.

- Safety hazards for the operator due to flying debris or equipment malfunctions.

9. How do you calculate the cutting speed and feed rate for spiral bevel gear generation?

- Consider the material properties of the workpiece.

- Use formulas provided by the machine manufacturer or cutting tool supplier.

- Adjust the cutting speed and feed rate based on the desired surface finish and gear quality.

- Monitor the cutting process and make adjustments as necessary to optimize performance.

10. Explain how to use a compound angle calculator to calculate the settings for spiral bevel gear generation.

- Input the gear parameters, such as the number of teeth, pitch, and spiral angle.

- Select the appropriate cutter head and arbor.

- Calculate the head angle and cutter angle using the compound angle calculator.

- Set the machine’s axis settings according to the calculated angles.

- Verify the setup by cutting a test gear and inspecting the tooth profile.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spiral Bevel Gear Generator Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spiral Bevel Gear Generator Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Spiral Bevel Gear Generator Set-Up Operator is responsible for setting up and operating a spiral bevel gear generator, a machine that manufactures spiral bevel gears, which are used in a variety of industrial applications. Key responsibilities include:

1. Set-Up and Calibration

Set up and calibrate the spiral bevel gear generator according to specifications.

- Install and secure the workpiece on the machine.

- Set the cutting parameters, such as speed, feed, and depth of cut, based on the specific gear requirements.

2. Operation

Operate the spiral bevel gear generator to cut the gears.

- Monitor the cutting process and make adjustments as needed to ensure the accuracy and quality of the gears.

- Inspect the finished gears to ensure they meet specifications.

3. Tooling and Maintenance

Maintain the spiral bevel gear generator and tooling.

- Clean and lubricate the machine and its components.

- Replace or sharpen cutting tools as necessary.

- Perform preventive maintenance tasks to ensure the machine operates smoothly and efficiently.

4. Quality Assurance

Ensure the quality of the gears produced by the spiral bevel gear generator.

- Inspect the gears at various stages of the manufacturing process to ensure they meet specifications.

- Keep records of the inspection results and any corrective actions taken.

Interview Tips

To ace the interview for a Spiral Bevel Gear Generator Set-Up Operator position, it is important to prepare thoroughly and demonstrate your skills and experience. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and values. Learn about the specific requirements of the Spiral Bevel Gear Generator Set-Up Operator role and how your skills and experience align with them.

- Visit the company’s website and social media pages.

- Read industry publications and articles to gain insights into the company’s operations and the role’s responsibilities.

2. Practice Your Answers

Prepare your answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Practice delivering your responses clearly and concisely, highlighting your relevant skills and experience.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your work.

- Ask a friend or family member to conduct a mock interview with you.

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge of spiral bevel gear generator operations. Discuss your experience in setting up, operating, and maintaining the machine.

- Quantify your experience by providing specific examples of the number of gears you have produced or the quality standards you have achieved.

- If you have any certifications or training in spiral bevel gear generator operations, be sure to mention them.

4. Show Your Quality Orientation

Discuss your commitment to quality and your attention to detail. Explain how you ensure the accuracy and precision of the gears produced by the spiral bevel gear generator.

- Describe your experience in using inspection equipment and following quality control procedures.

- Explain how you handle and resolve any quality issues that arise during the production process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spiral Bevel Gear Generator Set-Up Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.