Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spiral Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

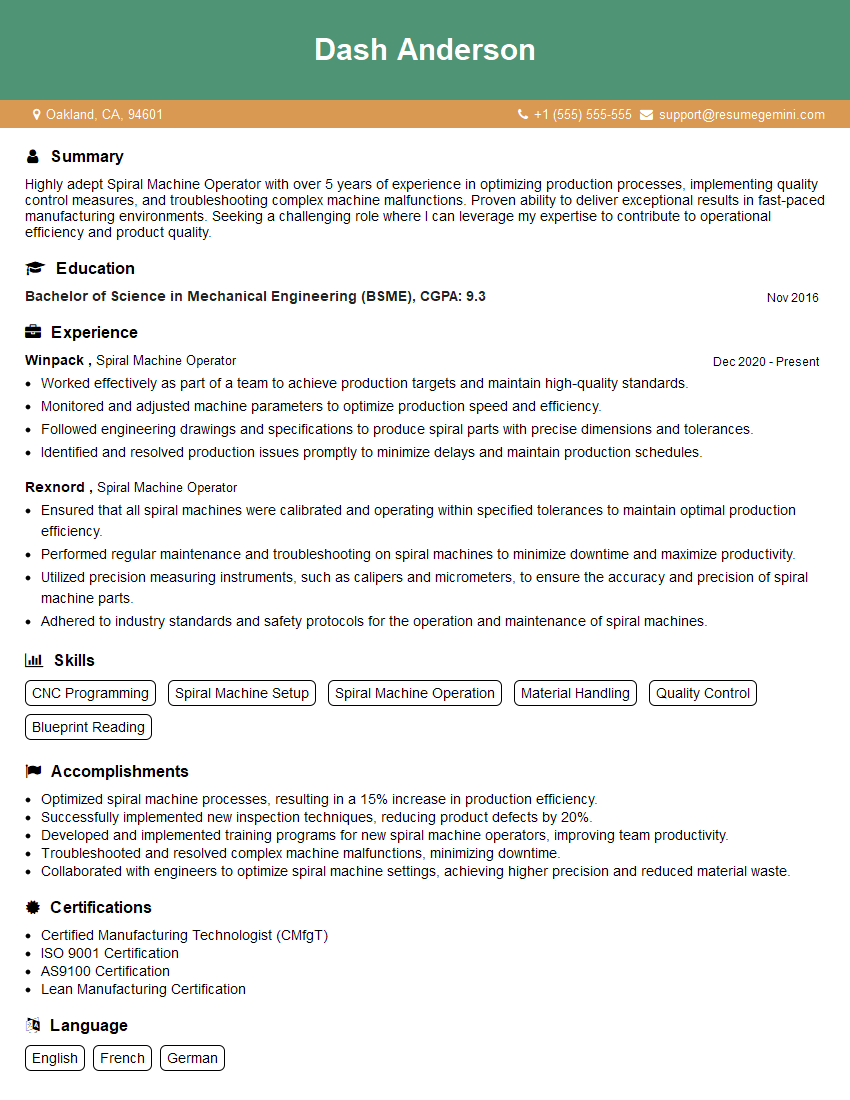

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spiral Machine Operator

1. Describe the process of setting up a spiral machine for a new job.

- Review the job specifications and material requirements.

- Select and install the appropriate tooling and fixtures.

- Set the machine parameters, including spindle speed, feed rate, and coolant flow.

- Load the material and secure it in the machine.

- Run a test cycle to verify the setup and make any necessary adjustments.

2. How do you ensure that the spiral machine is operating at optimal efficiency?

Performance monitoring

- Monitor cycle times and production rates.

- Track tool wear and make adjustments as needed.

- Inspect finished parts for quality and dimensional accuracy.

Preventive maintenance

- Regularly clean and lubricate the machine.

- Inspect and tighten bolts and screws.

- Calibrate the machine and sensors.

3. What are the key safety precautions to observe when operating a spiral machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Never operate the machine with the guards removed.

- Be aware of the location of the emergency stop button.

- Follow all established safety protocols and procedures.

4. How do you troubleshoot common problems that may arise during spiral machine operation?

- Identify the symptoms of the problem and observe the machine’s operation.

- Check for any error messages or codes displayed on the machine’s interface.

- Inspect the tooling, fixtures, and material for any damage or wear.

- Consult with the machine’s manufacturer or a qualified technician if necessary.

- Take appropriate corrective actions to resolve the problem and restore optimal performance.

5. What techniques do you use to improve the accuracy and precision of the spiral machine’s operations?

- Precision tooling and fixtures ensure accurate part dimensions.

- Regular calibration of the machine and sensors minimizes errors.

- Compensating for thermal expansion and contraction maintains dimensional stability.

- Advanced control systems optimize machine movements and reduce vibration.

- Statistical process control (SPC) helps identify and eliminate sources of variation.

6. Describe your experience with different types of spiral machines.

- Horizontal spindle spiral machines

- Vertical spindle spiral machines

- CNC spiral machines

- Multi-spindle spiral machines

7. How do you stay up-to-date with the latest advancements in spiral machine technology?

- Attend industry conferences and exhibitions.

- Read technical journals and white papers.

- Participate in online forums and discussion groups.

- Consult with experts and vendors.

8. What are your strengths and weaknesses as a Spiral Machine Operator?

Strengths

- Proficient in setting up and operating various types of spiral machines.

- Strong understanding of machine parameters, tooling, and materials.

- Excellent troubleshooting skills and problem-solving abilities.

- Attention to detail and commitment to producing high-quality parts.

Weaknesses

- Limited experience with automated spiral machines.

- Need to improve time management skills when working with multiple machines.

9. Why are you interested in working as a Spiral Machine Operator at our company?

- Interested in the company’s reputation for producing high-quality products.

- Excited about the opportunity to contribute to the team’s success.

- Value the company’s commitment to safety and training.

10. What are your salary expectations for this position?

- Research industry benchmarks and company compensation practices.

- Consider your experience, skills, and qualifications.

- Be prepared to negotiate and provide a range of acceptable salaries.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spiral Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spiral Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spiral Machine Operators are responsible for operating spiral machines to produce a variety of products, including springs, wire forms, and other metal components. Their duties can vary depending on the specific industry and the type of equipment used, but some common responsibilities include:1. Machine Operation

Setting up and operating spiral machines according to established specifications.

- Reading and interpreting blueprints and work orders.

- Loading raw materials and adjusting machine settings.

- Monitoring machine operation and making adjustments as needed.

- Ensuring that the machine is running smoothly and producing quality products.

2. Quality Control

Inspecting and testing products to ensure that they meet quality standards.

- Conducting visual inspections for defects such as burrs, cracks, and deformations.

- Using measuring instruments to verify dimensions and tolerances.

- Performing non-destructive testing to ensure the integrity of products.

- Maintaining records of all quality control checks and inspections.

3. Maintenance

Maintaining and repairing spiral machines to ensure optimal performance.

- Performing routine maintenance tasks such as lubrication, cleaning, and adjustments.

- Diagnosing and troubleshooting machine problems.

- Replacing worn or damaged parts.

- Working with maintenance technicians to ensure that the machine is running safely and efficiently.

4. Process Improvement

Working with management and other team members to identify and implement process improvements.

- Analyzing production data to identify areas for improvement.

- Suggesting and implementing changes to improve efficiency and quality.

- Training other employees on new processes and procedures.

- Staying up-to-date on industry best practices and technological advancements.

Interview Tips

1. Research the Company and the Role

Before the interview, take the time to research the company, its products, and its culture. This will help you to understand the organization and the role you are applying for, and it will also show the interviewer that you are interested in the opportunity.

- Visit the company’s website and social media pages.

- Read articles about the company and its industry.

- Talk to people who work at the company, if possible.

- Prepare questions to ask the interviewer about the company and the role.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses?” Practice answering these questions in advance so that you can deliver clear and concise responses.

- Use the STAR method to answer questions about your experience and skills.

- Focus on highlighting your most relevant skills and experiences.

- Use specific examples to support your answers.

- Be concise and to the point.

3. Dress Professionally and Arrive on Time

Your appearance and punctuality will make a big impression on the interviewer, so make sure to dress professionally and arrive on time for your interview.

- Choose clothing that is clean, pressed, and appropriate for the industry and company you are applying to.

- Arrive at the interview location 5-10 minutes early.

- Be polite and respectful to everyone you encounter, including the receptionist and other employees.

4. Be Enthusiastic and Engaging

The interviewer wants to see that you are enthusiastic about the job and passionate about the industry. Be positive, friendly, and engaged throughout the interview.

- Make eye contact with the interviewer.

- Smile and be friendly.

- Ask questions about the company and the role.

- Follow up after the interview with a thank-you note.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spiral Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.