Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Splash Line Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

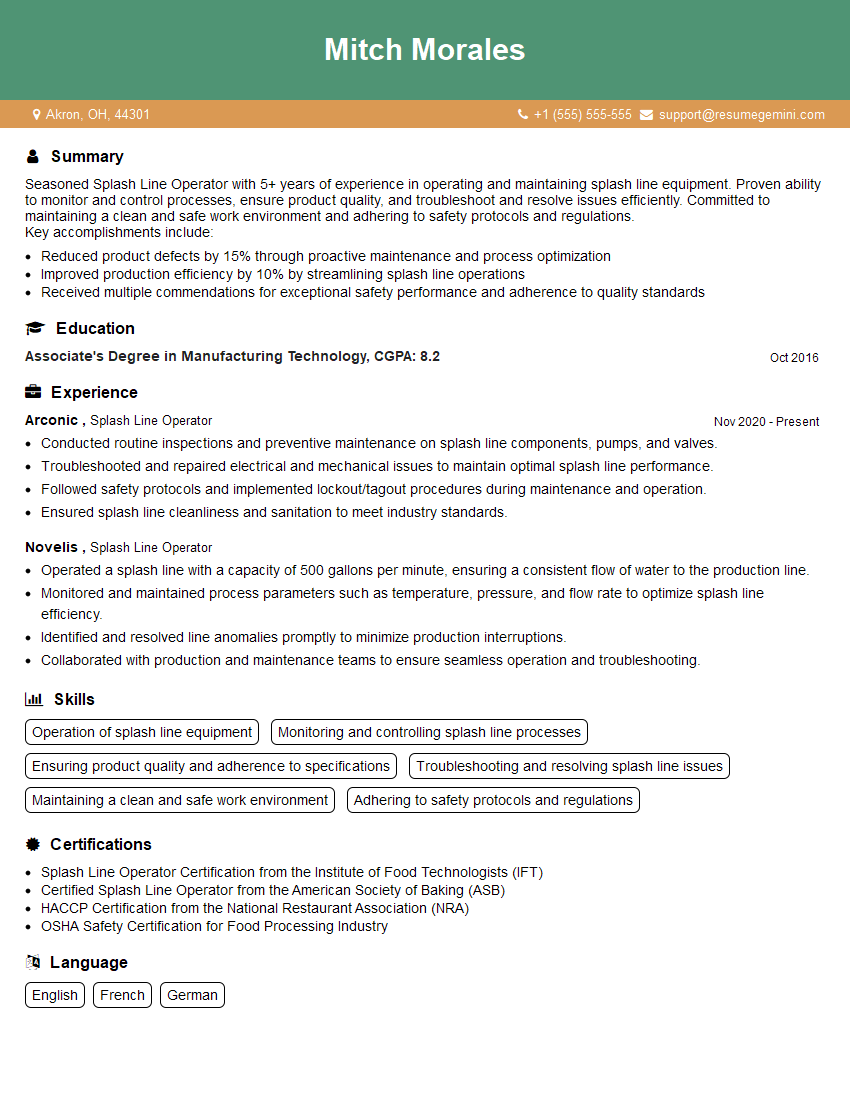

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Splash Line Operator

1. Explain the process of splash line lubrication and its importance in industrial machinery?

Splash line lubrication is a method of lubrication in which a pool of lubricant is maintained at a constant level in the sump of a machine. The rotating parts of the machine dip into the lubricant and splash it onto the bearings and other moving parts. This method is simple and effective, and it is often used in applications where it is difficult or impossible to use other methods of lubrication, such as grease or oil pumps.

- Splash line lubrication is a simple and effective method of lubrication.

- It is often used in applications where it is difficult or impossible to use other methods of lubrication.

- Splash line lubrication helps to reduce friction and wear on moving parts.

- It helps to extend the life of machinery.

2. Describe the safety precautions that should be taken when working with splash line lubrication systems?

Personal protective equipment

- Wear gloves and eye protection when working with splash line lubrication systems.

- Avoid contact with the lubricant.

- Keep the work area clean and free of debris.

Maintenance procedures

- Follow the manufacturer’s instructions for maintaining the splash line lubrication system.

- Inspect the system regularly for leaks and other problems.

- Change the lubricant regularly.

3. What are the different types of splash line lubrication systems?

- Dipping lubrication: In this type of system, the rotating parts of the machine dip into a pool of lubricant. This is the simplest type of splash line lubrication system.

- Splash lubrication: In this type of system, the lubricant is splashed onto the moving parts by the rotating parts of the machine. This type of system is more effective than dipping lubrication, but it requires a higher level of lubricant.

- Spray lubrication: In this type of system, the lubricant is sprayed onto the moving parts by a nozzle. This type of system is the most effective, but it also requires the highest level of lubricant.

4. What are the advantages and disadvantages of using splash line lubrication systems?

Advantages

- Splash line lubrication systems are simple and easy to maintain.

- They are relatively inexpensive to install and operate.

- They can be used in a wide variety of applications.

Disadvantages

- Splash line lubrication systems can be messy and can create a fire hazard.

- They can be inefficient, and they can lead to lubricant contamination.

- They can be difficult to use in applications where the machinery is exposed to water or other contaminants.

5. What are some of the common problems that can occur with splash line lubrication systems?

- Lubricant contamination: This can occur when the lubricant becomes contaminated with water, dirt, or other contaminants.

- Lubricant leaks: This can occur when the seals in the system fail.

- Overheating: This can occur when the lubricant becomes too hot.

- Pump failure: This can occur when the pump that supplies the lubricant to the system fails.

6. How can you troubleshoot a splash line lubrication system?

- Check the lubricant level: The lubricant level should be maintained at the recommended level.

- Inspect the lubricant for contamination: The lubricant should be free of water, dirt, and other contaminants.

- Check for leaks: The system should be inspected for leaks.

- Check the pump: The pump should be inspected for proper operation.

7. What are some tips for maintaining a splash line lubrication system?

- Maintain the lubricant level: The lubricant level should be maintained at the recommended level.

- Change the lubricant regularly: The lubricant should be changed regularly according to the manufacturer’s instructions.

- Inspect the system regularly: The system should be inspected regularly for leaks and other problems.

- Clean the system regularly: The system should be cleaned regularly to remove dirt and other contaminants.

8. What are the different types of lubricants that can be used in splash line lubrication systems?

- Mineral oils: These are the most common type of lubricant used in splash line lubrication systems.

- Synthetic oils: These are more expensive than mineral oils, but they offer better performance.

- Grease: Grease is a semi-solid lubricant that can be used in splash line lubrication systems.

9. How do you select the right lubricant for a splash line lubrication system?

- Consider the operating conditions: The lubricant should be able to withstand the operating conditions, such as temperature, pressure, and speed.

- Consider the type of machinery: The lubricant should be compatible with the type of machinery being lubricated.

- Consider the cost: The lubricant should be cost-effective.

10. What are the environmental considerations associated with splash line lubrication systems?

- Lubricant disposal: The lubricant should be disposed of properly.

- Air pollution: The lubricant can create air pollution.

- Water pollution: The lubricant can pollute water sources.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Splash Line Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Splash Line Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Splash Line Operator is responsible for the efficient and safe operation of the splash line, ensuring that products are processed according to established standards and quality requirements.

1. Product Handling and Processing

Handles products, including raw materials and finished goods, with precision and care in accordance with safety regulations and company procedures.

- Inspect products for quality, weight, and condition before processing.

- Load and unload products onto and off the splash line, using proper handling techniques.

2. Equipment Operation and Maintenance

Maintains and operates splash line equipment, ensuring optimal performance and efficiency.

- Set up, operate, and clean equipment, including conveyors, sorters, slicers, and packaging machines.

- Monitor equipment performance and proactively identify and address any potential issues.

3. Quality Control and Inspection

Inspects products throughout the processing line, identifying and removing defective or non-compliant items.

- Conduct visual inspections and use measurement tools to ensure products meet specifications.

- Maintain records of quality inspections and report any deviations or non-conformances.

4. Sanitation and Safety

Maintains a clean and safe work environment by adhering to established sanitation and safety protocols.

- Sanitize equipment, work surfaces, and utensils regularly.

- Wear appropriate personal protective equipment (PPE) and follow proper safety procedures.

Interview Tips

Preparing thoroughly for an interview is crucial to making a positive impression on potential employers. Here are some tips to help you ace your interview for a Splash Line Operator position:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by researching the company’s background, industry, and the specific role you’re applying for.

- Visit the company’s website to learn about their mission, values, and products/services.

- Review the job description carefully to identify the key responsibilities and qualifications.

2. Practice Your Answers to Common Interview Questions

Prepare responses to common interview questions related to your skills, experience, and why you’re interested in the position.

- Highlight your product handling, equipment operation, quality control, and sanitation experience.

- Emphasize your commitment to safety and maintaining a clean work environment.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions shows your engagement and interest in the role and the company.

- Inquire about the company’s growth plans and industry trends.

- Ask about specific responsibilities and expectations for the Splash Line Operator position.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview and arrive punctually.

- Wear business casual attire or a clean, pressed uniform.

- Plan your route and leave ample time to avoid any unexpected delays.

5. Be Confident and Enthusiastic

Confidence and enthusiasm can make a significant difference in an interview. Believe in your abilities and convey your passion for the role.

- Maintain eye contact, speak clearly, and project a positive attitude throughout the interview.

- Thank the interviewer for their time and express your interest in the position.

Next Step:

Now that you’re armed with the knowledge of Splash Line Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Splash Line Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini