Are you gearing up for a career in Splicer Apprentice? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Splicer Apprentice and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

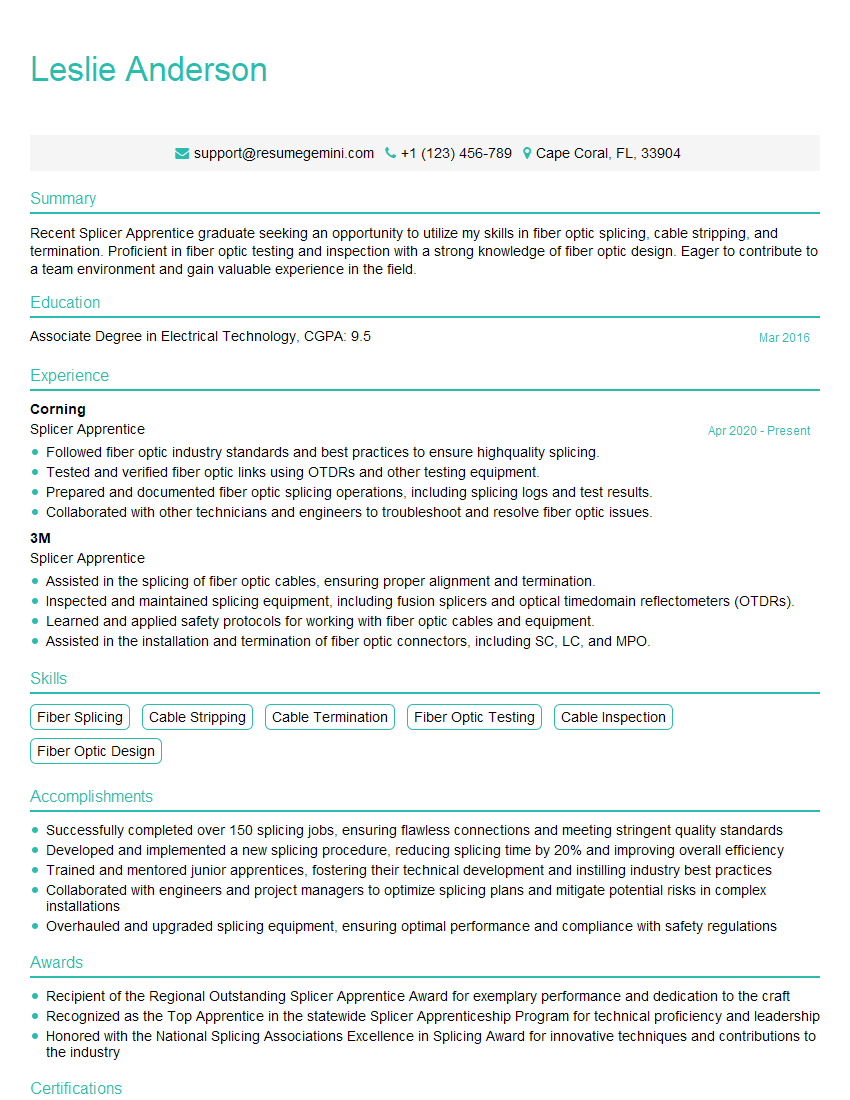

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Splicer Apprentice

1. Explain the process of fusion splicing.

Fusion splicing is a technique used to permanently join two optical fibers together. The process involves the following steps:

- Preparing the fibers by removing the protective coating and cleaving the ends to create a clean, perpendicular surface.

- Aligning the fiber ends using a fusion splicer.

- Applying an electric arc to fuse the two ends together.

- Inspecting the joint to ensure that it is properly fused.

2. What are the different types of fusion splicers?

There are two main types of fusion splicers: core alignment splicers and cladding alignment splicers.

Core alignment splicers

- Align the cores of the two fibers together.

- Typically used for splicing single-mode fibers.

Cladding alignment splicers

- Align the cladding of the two fibers together.

- Typically used for splicing multi-mode fibers.

3. What are the key parameters to consider when fusion splicing?

The key parameters to consider when fusion splicing are:

- Fiber type: Single-mode or multi-mode

- Fiber diameter

- Cleave angle

- Fusion splice loss

- Environmental conditions

4. What are the common causes of fusion splice failure?

The common causes of fusion splice failure are:

- Poor fiber preparation

- Improper alignment of the fibers

- Excessive fusion power

- Environmental contamination

- Fiber damage

5. What are the steps involved in mechanical splicing?

Mechanical splicing involves the use of a mechanical splice protector to join two optical fibers together. The process involves the following steps:

- Preparing the fibers by removing the protective coating and cleaving the ends to create a clean, perpendicular surface.

- Inserting the fibers into the splice protector.

- Crimping the splice protector to secure the fibers in place.

- Inspecting the joint to ensure that it is properly spliced.

6. What are the advantages and disadvantages of fusion splicing and mechanical splicing?

Fusion splicing

Advantages- Lower optical loss

- More reliable

- Smaller and more compact

- More expensive

- Requires specialized equipment and training

Mechanical splicing

Advantages- Less expensive

- Easier to perform

- Higher optical loss

- Less reliable

- Larger and less compact

7. How do you troubleshoot a failed splice?

To troubleshoot a failed splice, I would follow these steps:

- Inspect the splice for any obvious damage.

- Use an optical loss test set to measure the loss across the splice.

- If the loss is high, I would re-splice the fibers.

- If the splice is still failing, I would consult with a more experienced technician.

8. What safety precautions should be taken when working with optical fiber?

When working with optical fiber, it is important to take the following safety precautions:

- Wear safety glasses.

- Do not look directly into the laser beam.

- Be aware of the potential for electrical shock.

- Use proper grounding and bonding techniques.

- Follow all manufacturer’s instructions.

9. What are the different types of optical fiber connectors?

The different types of optical fiber connectors include:

- SC

- LC

- FC

- ST

- MTP

10. What is the difference between single-mode and multi-mode fiber?

Single-mode fiber has a smaller core diameter than multi-mode fiber. This allows it to transmit light in only one mode, which results in less signal loss and dispersion. Multi-mode fiber has a larger core diameter than single-mode fiber. This allows it to transmit light in multiple modes, which results in more signal loss and dispersion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Splicer Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Splicer Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Splicer Apprentice assists experienced professionals in performing various aspects of splicing activities. Key responsibilities include:

1. Splicing Operations Support

Supports splicing operations, including:

- Preparing splice cases and cables for splicing

- Assisting with fiber optic splicing processes

2. Equipment Maintenance and Calibration

Assists with the maintenance and calibration of splicing equipment

- Cleaning and inspecting tools and equipment

- Calibrating splicing machines and other equipment

3. Material Management

Assists with material management, including:

- Maintaining inventory of splicing supplies

- Ordering and receiving splicing materials

4. Documentation and Record Keeping

Assists with documentation and record keeping, including:

- Recording splicing data and test results

- Preparing splicing reports and documentation

Interview Tips

To ace the interview for a Splicer Apprentice position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company and the specific role. Understand the company’s products, services, culture, and values. Learn about the industry and the key responsibilities of a Splicer Apprentice.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Network with professionals in the field.

2. Practice Your Answers to Common Interview Questions

Prepare for common interview questions related to your skills, experience, and qualifications. Practice answering these questions clearly and concisely.

- Tell me about your experience with fiber optic splicing.

- What are the different types of splicing techniques?

- How do you ensure the quality of your splicing work?

3. Highlight Your Soft Skills

In addition to technical skills, employers also value soft skills such as teamwork, communication, and problem-solving. Showcase your ability to work effectively in a team and your proactive approach to problem resolution.

- Describe a time when you worked effectively as part of a team.

- Give an example of a problem you encountered and how you resolved it.

- How do you stay up-to-date on the latest splicing technologies and techniques?

4. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the role and the industry. Dress professionally, maintain eye contact, and speak confidently. Ask thoughtful questions about the company and the position to show your engagement.

- Why are you interested in this role and our company?

- What are your career goals and how does this position align with them?

- Do you have any questions for me about the role or the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Splicer Apprentice interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!