Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Splicer Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Splicer Helper so you can tailor your answers to impress potential employers.

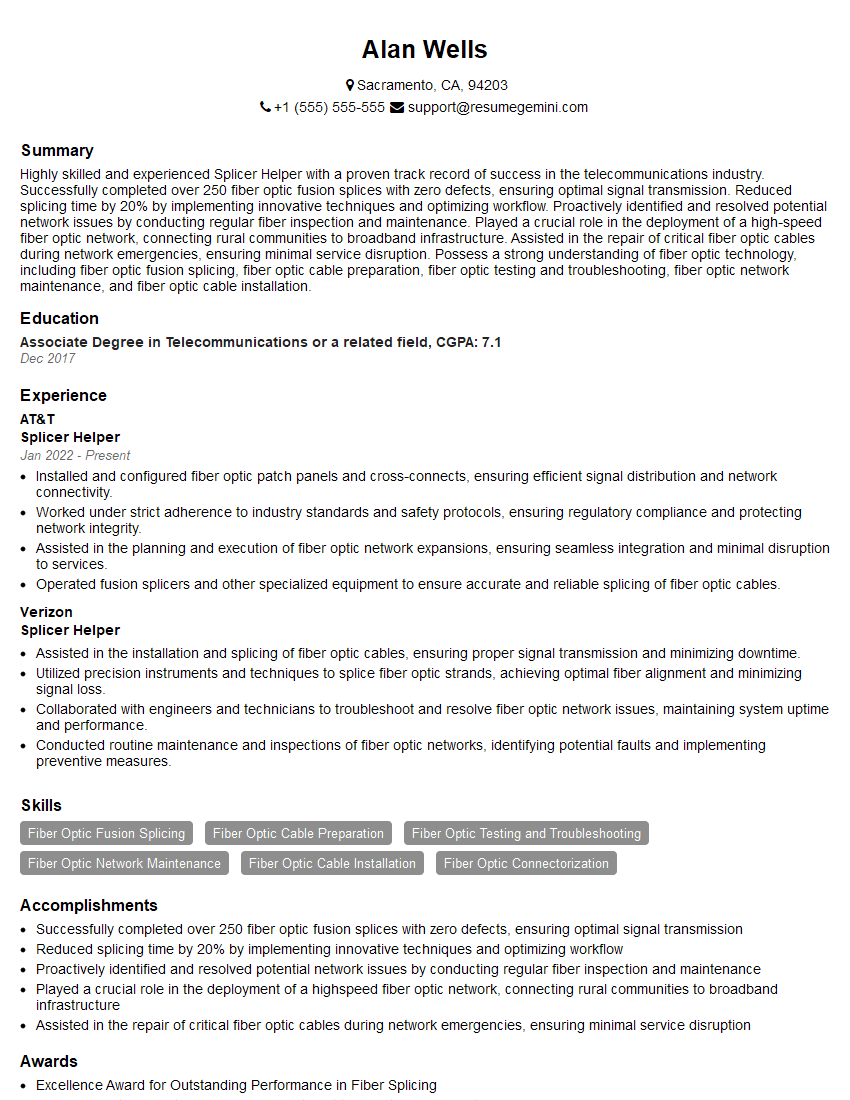

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Splicer Helper

1. How do you ensure the quality of fiber optic cables during splicing?

To ensure the quality of fiber optic cables during splicing, I follow these key steps:

- Inspection: Before splicing, I carefully inspect the cables to identify any damage or imperfections that could affect the splice quality.

- Cable Preparation: I properly prepare the cables by stripping the outer jacket, cleaning the fibers, and aligning them using a fiber optic cleaver.

- Splicing Technique: I use precision splicing techniques, such as arc fusion splicing or mechanical splicing, to join the fibers with minimal loss and ensure a strong connection.

- Testing: After splicing, I thoroughly test the cables using an optical time-domain reflectometer (OTDR) to verify the quality of the splice and identify any potential issues.

2. Describe the different types of fiber optic cables and their applications.

There are various types of fiber optic cables, each with its own characteristics and applications:

Single-Mode Fiber (SMF):

- Transmits a single mode of light, resulting in lower loss and higher bandwidth.

- Suitable for long-distance applications, such as submarine cables and backbone networks.

Multi-Mode Fiber (MMF):

- Transmits multiple modes of light, allowing for higher data rates over shorter distances.

- Used in premises networks, data centers, and short-haul applications.

Tight-Buffered Fiber:

- Has a tight buffer coating around the fiber, making it more rugged and resistant to damage.

- Suitable for outdoor and harsh environments.

Loose-Tube Fiber:

- Has a loose buffer tube around the fiber, providing protection and flexibility.

- Used in indoor applications, such as data centers and office buildings.

3. How do you handle and store fiber optic cables to minimize damage?

To minimize damage to fiber optic cables during handling and storage, I adhere to the following practices:

- Avoid Kinking and Bending: I carefully avoid kinking or bending the cables beyond their specified bend radius to prevent damage to the fibers.

- Proper Coiling: I coil the cables using the overhand method to prevent twisting and stress on the fibers.

- Protective Packaging: I store the cables in protective packaging, such as reels or spools, to shield them from physical impacts.

- Environmental Control: I ensure proper environmental conditions during storage, including controlled temperature and humidity, to prevent fiber degradation.

4. What are the safety precautions you observe when working with fiber optics?

When working with fiber optics, I prioritize safety by adhering to the following precautions:

- Eye Protection: I wear protective goggles or glasses to shield my eyes from potential laser exposure.

- Skin Protection: I use gloves to minimize skin contact with fibers and avoid cuts or abrasions.

- Proper Handling: I handle fiber optic cables with care to prevent damage and sharp edges.

- Laser Safety: I am cautious when using laser source equipment, ensuring proper alignment and following established safety protocols.

- Workspace Cleanliness: I maintain a clean workspace to avoid contamination and potential hazards.

5. Describe the process of preparing and splicing a fiber optic cable.

Preparing a Fiber Optic Cable:

- Strip the outer jacket using a fiber optic stripper.

- Clean the exposed fibers using alcohol and wipes.

- Use a fiber optic cleaver to make a precise and perpendicular cut on the fibers.

Splicing the Fiber Optic Cable:

- Align the prepared fiber ends using a splicing machine.

- Apply heat or an electrical arc to fuse the fibers together.

- Protect the splice using a splice protector or enclosure.

6. What are the different types of fiber optic connectors and their applications?

There are several types of fiber optic connectors, each designed for specific applications:

- SC Connector: General-purpose connector used in data centers and telecommunications networks.

- LC Connector: Small and compact connector, suitable for high-density applications.

- ST Connector: Durable connector commonly used in industrial environments.

- FC Connector: High-precision connector used in fiber-to-the-home (FTTH) and long-haul networks.

- MTP/MPO Connector: Multi-fiber connector used for high-bandwidth applications, such as data centers.

7. Explain the role of an optical time-domain reflectometer (OTDR) in fiber optic testing.

An optical time-domain reflectometer (OTDR) is a key tool used in fiber optic testing for the following purposes:

- Event Detection: Detects and locates events along the fiber, such as splices, connectors, and breaks.

- Distance Measurement: Measures the distance to events and the overall length of the fiber.

- Attenuation Measurement: Determines the power loss at different points along the fiber.

- Fault Isolation: Helps identify and isolate faults, such as breaks or high-loss splices.

8. Describe the different methods of terminating fiber optic cables.

Fiber optic cables can be terminated using various methods:

- Mechanical Splicing: Uses mechanical connectors to join the fibers without fusion.

- Fusion Splicing: Fuses the fiber ends together using heat or an electrical arc.

- Epoxy Splicing: Uses epoxy resin to bond the fiber ends together.

- Polishing: After splicing, the connector end is polished to ensure a smooth surface for optimal light transmission.

9. What are the common problems encountered during fiber optic splicing and how do you resolve them?

Common problems encountered during fiber optic splicing include:

- High Insertion Loss: Caused by poor connector alignment or dirty fiber ends. Resolved by cleaning connectors and realigning fibers.

- Back Reflection: Occurs due to imperfections at the splice point. Resolved by optimizing splice parameters and using index-matching gels.

- Fiber Breakage: Can occur during preparation or splicing due to excessive bending or tension. Resolved by proper handling techniques and using the correct tools.

10. Explain the importance of documentation and record-keeping in fiber optic splicing.

Documentation and record-keeping are crucial in fiber optic splicing for several reasons:

- Traceability: Provides a record of the splicing process, materials used, and test results.

- Quality Control: Allows for the verification of splice quality and compliance with industry standards.

- Troubleshooting: Facilitates the identification and resolution of problems by providing detailed information about the splicing process.

- Maintenance and Repair: Serves as a reference for future maintenance or repair work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Splicer Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Splicer Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Splicer Helpers assist Splicers in the installation and maintenance of electrical cables by performing various tasks.

1. Assisting in Cable Preparation

Prepares cables for splicing by stripping insulation, cleaning conductors, and applying heat shrink tubing.

2. Soldering and Connecting Cables

Soldering and connecting cables by following electrical diagrams and ensuring proper connections.

3. Testing and Inspecting Cables

Testing and inspecting cables for continuity and insulation resistance to ensure they meet specifications.

4. Equipment Maintenance

Assisting in the maintenance of tools and equipment used in the splicing process, such as splicing machines and cable strippers.

Interview Tips

Preparing for an interview can increase your chances of success. Here are some tips to help you ace your interview for a Splicer Helper position:

1. Research the Company

Researching the company before the interview demonstrates your interest in the position and the organization. Learn about their history, values, and recent projects.

- Visit the company’s website.

- Read news articles and press releases.

- Follow their social media channels.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and prepared during the interview.

- Tell me about yourself?

Example Outline:

– Start with your educational background.

– Mention your work experience and skills.

– Explain why you are interested in this specific opportunity. - Why do you want to work for our company?

Example Outline:

– Mention the company’s reputation and values.

– Express your interest in the specific industry or products.

– Explain how your skills and experience align with the company’s needs.

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to emphasize your skills and experience that are relevant to the Splicer Helper position. Use specific examples to demonstrate your abilities.

- Mention your experience in cable preparation, installation, and testing.

- Emphasize your knowledge of electrical safety regulations.

- Share examples of projects where you have successfully assisted Splicers.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Ask about the company’s growth plans.

- Inquire about the training and development opportunities available.

- Ask about the company’s safety record and policies.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Splicer Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!