Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Splicing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

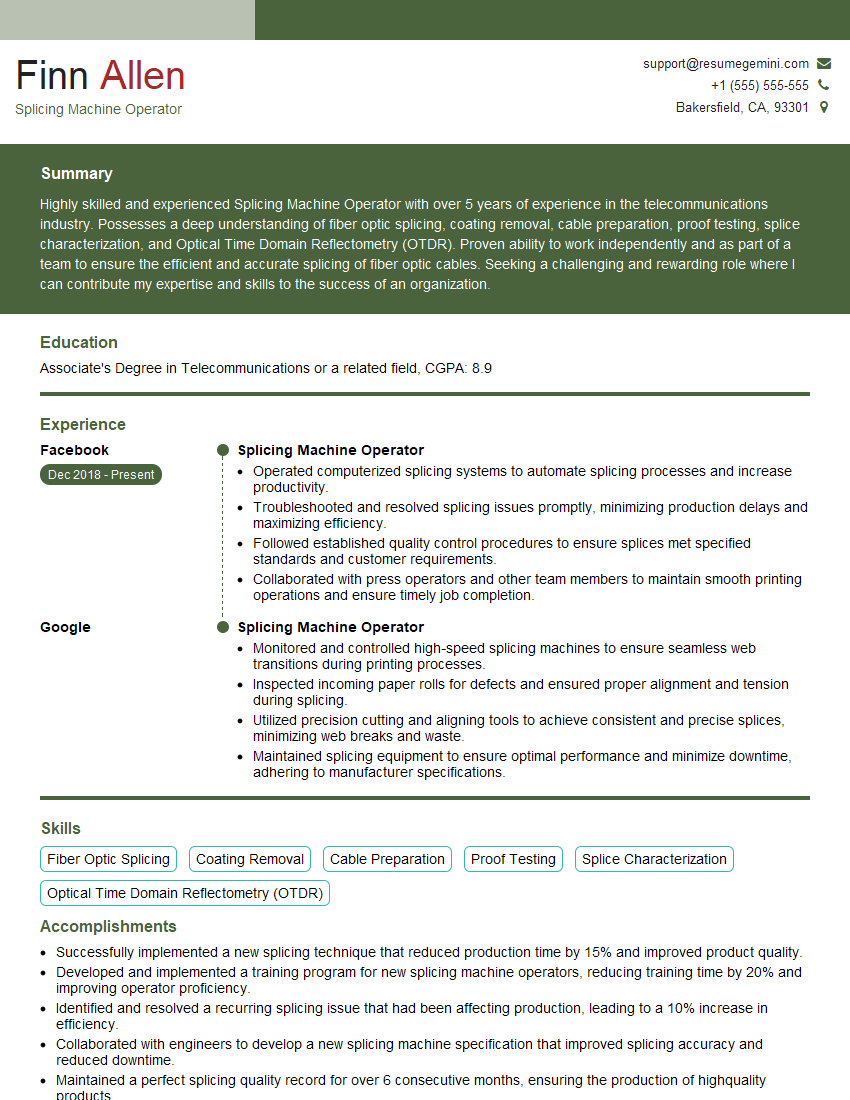

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Splicing Machine Operator

1. Describe the process of splicing optical fibers using a splicing machine.

- Prepare the optical fibers by stripping the outer jacket and cleaning the ends.

- Align the fibers in the splicing machine using the V-grooves.

- Initiate the splicing process, which involves melting and joining the fibers together.

- Inspect the splice joint using a microscope to ensure a strong and low-loss connection.

2. What are the different types of splicing machines available?

Arc Fusion Splicers

- Use an electric arc to melt and join the fibers.

- Provide precise alignment and low-loss connections.

Mechanical Splicers

- Use mechanical force to align and join the fibers.

- Less precise than arc fusion splicers, but faster and more portable.

3. How do you troubleshoot and repair common splicing errors?

- Identify the type of error (e.g., high loss, poor alignment).

- Check the equipment (e.g., splicing machine, fibers) for any defects.

- Re-splice the fibers using proper techniques.

- Inspect the splice joint again and perform any necessary adjustments.

4. What is the importance of proper splicing techniques?

- Ensure low-loss connections for efficient signal transmission.

- Minimize interference and signal degradation.

- Protect the optical fibers from damage and environmental factors.

5. Describe the safety precautions that should be taken when operating a splicing machine.

- Wear appropriate protective gear (e.g., safety glasses, gloves).

- Handle the fibers with care to prevent breakage or contamination.

- Use the splicing machine in a clean and well-lit area.

- Follow all manufacturer’s instructions for safe operation.

6. What is the difference between a single-mode and a multi-mode splicing machine?

- Single-mode splicers are used for single-mode fibers, which transmit light through a single path.

- Multi-mode splicers are used for multi-mode fibers, which transmit light through multiple paths.

7. What type of fiber connector would you recommend for a critical application requiring low loss?

8. How do you maintain and calibrate a splicing machine?

- Regularly clean the machine using appropriate solvents.

- Calibrate the machine using a certified fiber calibration kit.

- Follow the manufacturer’s recommended maintenance schedule.

9. What are the essential qualities of a successful Splicing Machine Operator?

- Attention to detail and precision

- Strong technical skills and understanding of fiber optics

- Ability to work independently and as part of a team

- Problem-solving and troubleshooting abilities

10. Describe your experience with different fiber optic cables and connectors.

- I have worked with single-mode and multi-mode fibers, as well as various types of connectors, including FC/APC, LC, and MTP/MPO.

- I am proficient in handling different cable types, such as armored cables, loose tube cables, and ribbon cables.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Splicing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Splicing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Splicing Machine Operator is a crucial role within the production process, responsible for ensuring the efficient and accurate splicing of materials.

1. Machine Operation and Maintenance

The Splicing Machine Operator operates and maintains splicing machines, ensuring they are in optimal condition for production.

- Adjust and calibrate machines to achieve precise splicing accuracy.

- Conduct routine maintenance and troubleshooting to prevent breakdowns and ensure smooth operation.

2. Materials Handling and Splicing

The Operator handles various materials and executes splicing processes to create seamless connections.

- Load and unload materials onto the splicing machine.

- Properly align and splice materials according to established specifications.

3. Quality Control and Inspection

The Operator performs quality checks and inspections to ensure the integrity of spliced materials.

- Inspect splices for defects or inconsistencies using visual aids or measuring instruments.

- Maintain accurate records of inspection results and report any anomalies to supervisors.

4. Safety and Compliance

The Operator adheres to safety regulations and follows established procedures to ensure a safe work environment.

- Follow safety protocols for operating machinery and handling materials.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

Preparing for an interview is key to showcasing your skills and qualifications effectively. Here are some tips to help you ace your Splicing Machine Operator interview:

1. Research the Company and Role

Thoroughly research the company and the specific role you are applying for. This will enable you to tailor your answers and demonstrate your understanding of the industry and the company’s needs.

- Visit the company website, read industry news, and look for information about the company’s culture and values.

- Identify the key responsibilities of the Splicing Machine Operator and how your skills and experience align with them.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your responses in advance. This will boost your confidence and help you present yourself clearly and effectively.

- Prepare answers to questions such as “tell me about yourself”, “why are you interested in this role”, and “what are your strengths and weaknesses”.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses and demonstrate your skills and accomplishments.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that make you an ideal candidate for the role.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Be prepared to discuss specific examples of your ability to operate and maintain splicing machines, handle materials effectively, and ensure quality control.

4. Showcase Your Interest and Enthusiasm

Show your genuine interest in the role and the company. This will convey your passion for the industry and make a positive impression on the interviewer.

- Prepare questions to ask the interviewer about the company, the role, and the industry.

- Express your enthusiasm for the opportunity to contribute to the team and the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Splicing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!