Are you gearing up for an interview for a Splicing Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Splicing Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

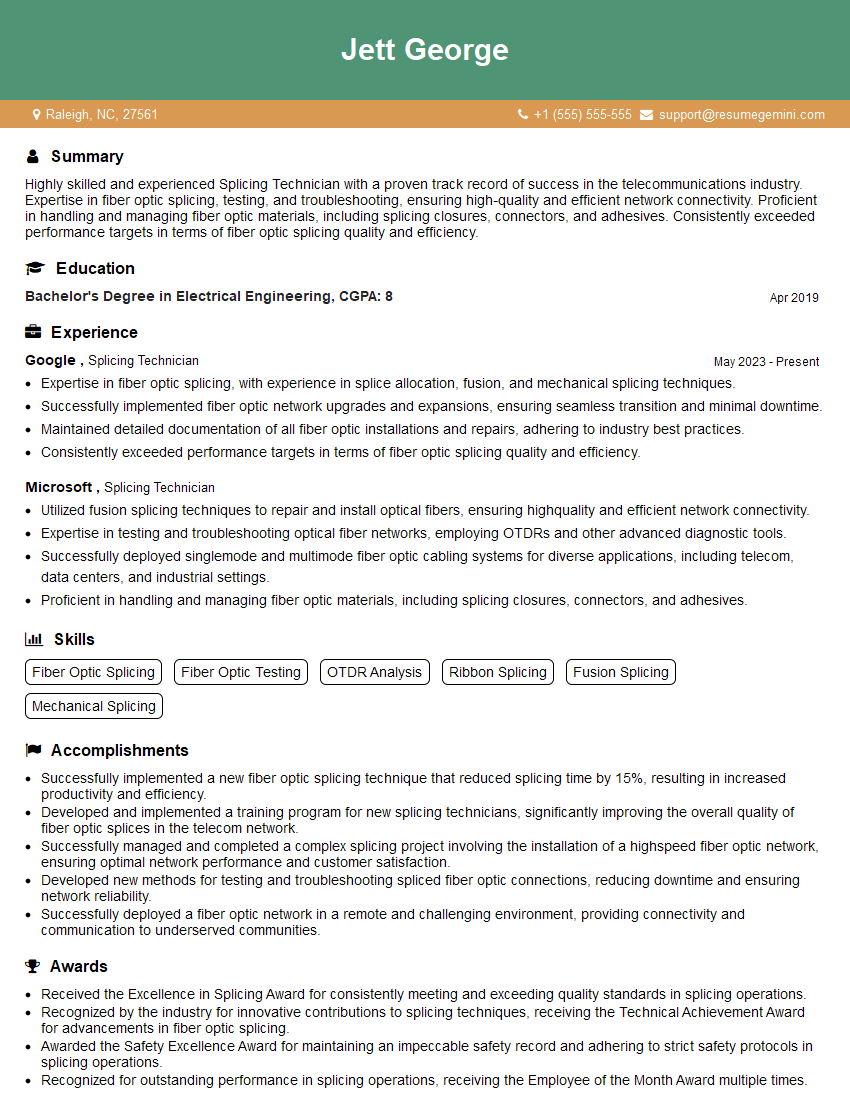

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Splicing Technician

1. What are the different types of fiber optic cables used in splicing?

- Single-mode fiber (SMF) is used for long-distance transmission and has a smaller core size than multi-mode fiber.

- Multi-mode fiber (MMF) is used for shorter distances and has a larger core size than single-mode fiber.

- Ribbon fiber is a type of multi-mode fiber that is made up of multiple fibers that are bundled together.

2. What are the different types of splices?

- Fusion splice is a permanent splice that is made by melting the ends of two fibers together.

- Mechanical splice is a temporary splice that is made by crimping or clamping two fibers together.

3. What is the difference between a splice and a connector?

- A splice is a permanent joint between two fibers, while a connector is a temporary joint that can be easily disconnected.

- Splices are typically made by fusion splicing or mechanical splicing, while connectors are typically made by crimping or clamping.

4. What are the steps involved in splicing a fiber optic cable?

- Prepare the fiber by stripping the jacket and buffer.

- Clean the fiber ends.

- Align the fiber ends.

- Fuse the fiber ends together.

- Protect the splice.

5. What are the different types of splicing equipment?

- Fusion splicer

- Mechanical splicer

- Splice tray

- Fiber cleaver

- Fiber stripper

6. What are the safety precautions that should be taken when splicing fiber optic cables?

- Wear safety glasses.

- Use a sharp fiber cleaver.

- Do not look directly at the laser beam from the fusion splicer.

- Handle the fiber optic cable with care.

- Follow the manufacturer’s instructions for the splicing equipment.

7. What are the troubleshooting tips for fiber optic splices?

- Check the splice for any physical damage.

- Clean the fiber ends.

- Realign the fiber ends.

- Refuse the splice.

- Replace the splice if necessary.

8. What are the different types of fiber optic connectors?

- SC connector

- LC connector

- FC connector

- ST connector

- MTP connector

9. What are the steps involved in terminating a fiber optic cable?

- Prepare the fiber by stripping the jacket and buffer.

- Clean the fiber ends.

- Insert the fiber into the connector.

- Crimp or clamp the connector.

- Protect the connector.

10. What are the different types of fiber optic test equipment?

- Optical power meter

- Optical loss test set

- Optical time domain reflectometer (OTDR)

- Fiber identifier

- Visual fault locator

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Splicing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Splicing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Splicing Technicians are skilled craftspeople responsible for the installation, maintenance, and repair of fiber optic cables and associated equipment.

1. Cable Preparation and Splicing

Prepare and splice fiber optic cables using specialized tools and techniques to ensure optimal signal transmission.

- Clean and prepare fiber optic cables for splicing.

- Utilize fusion splicers and mechanical splicers to join fiber optic cables.

2. Fiber Optic Testing

Conduct various tests on fiber optic cables and components to verify performance and troubleshoot issues.

- Perform optical time domain reflectometry (OTDR) testing to locate faults and measure cable parameters.

- Conduct continuity and attenuation tests to ensure signal quality.

3. Equipment Installation and Maintenance

Install and maintain fiber optic equipment, such as splice enclosures, distribution frames, and optical transceivers.

- Mount and configure splice enclosures and distribution frames.

- Maintain and repair optical transceivers and other equipment components.

4. Documentation and Reporting

Maintain accurate documentation and records of all work performed, including test results and splicing procedures.

- Create splice and test reports for customer verification.

- Maintain records of cable inventory and equipment usage.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Splicing Technician interview:

1. Research the Company and Position

Familiarize yourself with the company, its products or services, and the specific requirements of the Splicing Technician role. This knowledge will demonstrate your genuine interest and preparedness.

- Visit the company website and review their offerings.

- Research industry trends and advancements related to fiber optic technology.

2. Practice Your Technical Skills

Splicing Technicians rely heavily on technical proficiency. Practice your skills in fiber optic cable preparation, splicing, and testing to ensure you can confidently demonstrate your abilities during the interview.

- Set up a home lab or work with experienced technicians to refine your techniques.

- Obtain certifications or training to demonstrate your expertise.

3. Prepare for Behavioral Questions

In addition to technical questions, you will likely encounter behavioral questions during the interview. These questions aim to assess your problem-solving skills, teamwork abilities, and work ethic.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- Provide specific examples from your past experience that highlight your relevant skills.

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare questions that show you have researched the company and are genuinely curious about their operations.

- Inquire about the company’s current projects or technological advancements.

- Ask about opportunities for professional development or training within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Splicing Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.