Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spot Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

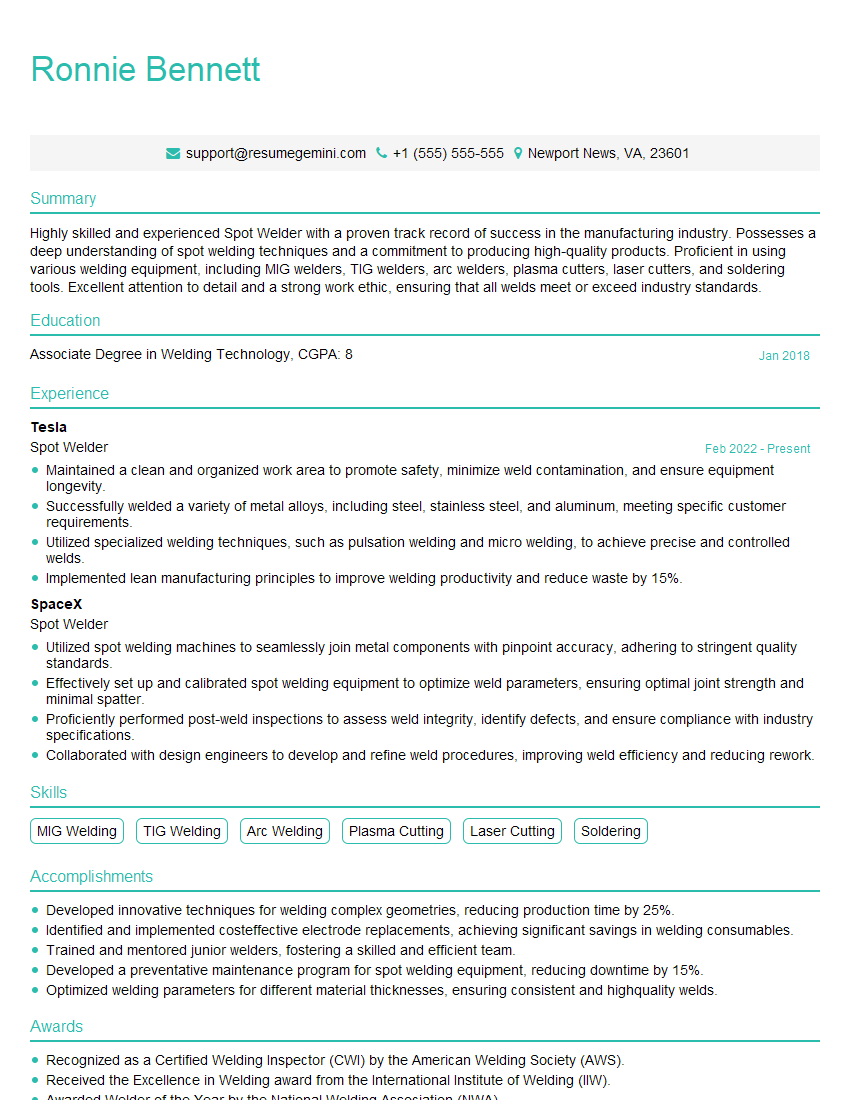

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spot Welder

1. Explain the principles of resistance spot welding.

Resistance spot welding is a fusion welding process that creates a weld by passing a high electrical current through the materials to be joined. The resistance to current flow in the materials causes them to heat and melt, forming a weld nugget. The key principles involved are:

- High electrical current

- Resistance to current flow

- Heat generation

- Weld nugget formation

2. What are the different types of resistance spot welding machines?

- Single phase machines: Use a single-phase transformer to convert AC power to a lower voltage and higher current.

- Three-phase machines: Use a three-phase transformer to provide a more balanced power supply.

- Inverter machines: Use solid-state electronics to convert AC power to high-frequency, high-current output.

- DC machines: Use a rectifier to convert AC power to DC power, which provides more precise current control.

3. Describe the key parameters in resistance spot welding.

- Welding current: Determines the heat generated and the size of the weld nugget.

- Welding time: Controls the duration of current flow and the depth of penetration.

- Electrode force: Maintains contact between the electrodes and the workpiece, influencing the resistance and weld quality.

- Hold time: Allows the weld nugget to solidify and cool under pressure.

- Electrode geometry: Affects the current density and the shape of the weld nugget.

4. What are the common defects in resistance spot welding?

- Spatter: Excess molten metal ejected from the weld zone due to high current or low electrode force.

- Burn-through: Holes formed in the workpiece due to excessive heat input.

- Cracks: Fractures in the weld zone due to thermal stresses or improper electrode placement.

- Cold welds: Weak welds formed due to insufficient heat or electrode force.

- Weld porosity: Gas bubbles trapped in the weld nugget, reducing strength.

5. Explain the importance of electrode maintenance in resistance spot welding.

- Clean electrodes: Remove oxides and dirt to ensure good electrical contact.

- Proper dressing: Shape the electrodes to provide the desired weld size and quality.

- Cooling: Prevent overheating and electrode damage by using coolants or water-cooled electrodes.

- Inspection and replacement: Regularly check electrodes for wear or damage and replace them when necessary.

6. Describe the safety precautions to be taken while performing resistance spot welding.

- Wear protective clothing: Gloves, apron, face shield, and earplugs to protect from heat, sparks, and noise.

- Secure workpiece: Prevent movement or shifting during welding.

- Proper grounding: Ensure electrical safety and prevent electrical shocks.

- Ventilation: Exhaust welding fumes to prevent respiratory hazards.

- Avoid touching hot surfaces: Use insulated tools and allow the weld area to cool before handling.

7. Explain the use of programmable logic controllers (PLCs) in resistance spot welding.

- Process control: Sequence and control the welding process automatically.

- Parameter adjustment: Allow for precise setting and adjustment of welding parameters.

- Data logging: Record and store welding data for quality control and traceability.

- Diagnostic capabilities: Identify and troubleshoot welding problems.

- Interface with other systems: Integrate with robots, conveyors, and other automation components.

8. Describe the process of welding dissimilar metals using resistance spot welding.

Welding dissimilar metals requires careful consideration of material properties and welding parameters:

- Material compatibility: Evaluate the compatibility of the materials to be welded and use appropriate filler materials if necessary.

- Adjusted parameters: Modify welding parameters (current, time, force, etc.) to accommodate the different properties of the metals.

- Electrode selection: Choose electrodes with materials and geometries suitable for welding the specific combination of metals.

- Post-welding treatments: Perform additional treatments such as heat treatment or coating to enhance the weld quality and properties.

9. Explain the role of quality control in resistance spot welding.

- Weld inspection: Verify the dimensions, strength, and quality of welds through visual inspection, destructive testing, or non-destructive testing.

- Process monitoring: Monitor welding parameters and ensure they are within acceptable ranges.

- Documentation and traceability: Maintain records of welding procedures, materials used, and inspection results for traceability and compliance.

- Continuous improvement: Analyze welding data to identify areas for process improvement and optimize weld quality.

10. Describe the latest advancements in resistance spot welding technology.

- Advanced controls: Utilize intelligent controllers and sensors for precise parameter control and process optimization.

- Adaptive welding: Adjust welding parameters dynamically based on real-time measurements of the welding process.

- Robotic automation: Integrate robots with spot welding machines for increased productivity and quality.

- Laser-assisted welding: Combine lasers with resistance spot welding to enhance weld strength and reduce defects.

- Friction stir spot welding: An alternative method that uses friction and stirring action to create strong welds without melting the materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spot Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spot Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spot welders are responsible for joining metal pieces together using a resistance welding process. They use a spot welder to apply heat and pressure to the metal pieces, causing them to fuse together. Spot welders work in various industries, including automotive, aerospace, and manufacturing.

1. Set up and operate spot welding equipment

Spot welders must be able to set up and operate spot welding equipment safely and efficiently. This includes setting the correct welding parameters, such as the welding current, voltage, and time.

- Follow all safety procedures when operating spot welding equipment.

- Inspect spot welding equipment regularly to ensure that it is in good working order.

2. Inspect and prepare metal pieces for welding

Spot welders must inspect and prepare metal pieces for welding to ensure that they are clean and free of any contaminants. They must also ensure that the metal pieces are properly aligned and positioned for welding.

- Inspect metal pieces for any defects or damage.

- Clean metal pieces using a wire brush or other cleaning method.

- Align and position metal pieces properly for welding.

3. Weld metal pieces together

Spot welders use a spot welder to weld metal pieces together. They apply heat and pressure to the metal pieces, causing them to fuse together. Spot welders must be able to control the welding process to ensure that the welds are strong and durable.

- Apply heat and pressure to metal pieces using a spot welder.

- Control the welding process to ensure that the welds are strong and durable.

- Inspect welds to ensure that they meet the required specifications.

4. Maintain a clean and organized work area

Spot welders must maintain a clean and organized work area to ensure that they can work safely and efficiently. They must also keep their tools and equipment in good working order.

- Keep work area clean and free of debris.

- Keep tools and equipment in good working order.

- Follow all safety procedures when working in a welding environment.

Interview Tips

To ace the interview for a spot welder position, you need to be prepared to answer questions about your experience and skills. You should also be able to demonstrate your knowledge of the welding process. Here are some tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on its website or in industry publications.

- Visit the company’s website to learn about its history, mission, and products or services.

- Read industry publications to learn about the latest trends in the welding industry.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Prepare a brief overview of your experience and skills that highlights your qualifications for the position.

- Identify the reasons why you are interested in the position and why you believe you are the right candidate for the job.

3. Be prepared to demonstrate your welding skills

In addition to answering questions about your experience and skills, you may also be asked to demonstrate your welding skills. This could involve welding a sample piece of metal or completing a specific welding task. It is important to be prepared for this part of the interview by practicing your welding skills beforehand.

- Practice welding different types of metal, including mild steel, stainless steel, and aluminum.

- Practice welding in different positions, such as flat, horizontal, and vertical.

4. Ask questions about the company and the position

At the end of the interview, you will likely be given the opportunity to ask questions about the company and the position. This is your chance to learn more about the company’s culture, the specific requirements of the job, and the opportunities for advancement. It is also a good way to show the interviewer that you are interested in the position and that you are serious about joining the company.

- Ask questions about the company’s culture and values.

- Ask questions about the specific requirements of the job and the opportunities for advancement.

- Ask questions about the company’s training and development programs.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spot Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!