Are you gearing up for an interview for a Spot Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Spot Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

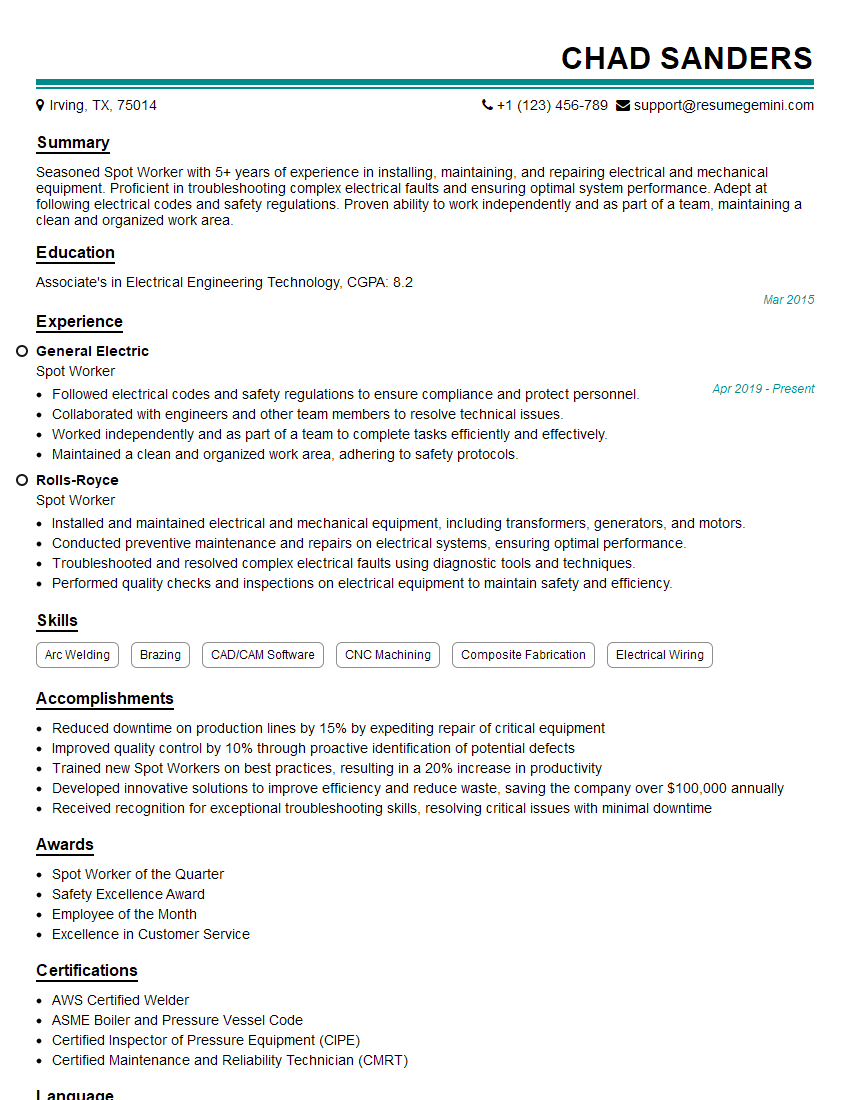

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spot Worker

1. What are the primary responsibilities of a Spot Welder?

The primary responsibilities of a Spot Welder include:

- Operate spot welding equipment to join metal components

- Ensure proper alignment and fit of components prior to welding

- Monitor welding process and adjust settings as needed

- Inspect welds for quality and adherence to specifications

- Maintain a clean and organized work area

2. What are the different types of spot welding?

- Resistance spot welding

- Capacitor discharge spot welding

- Stud welding

- Projection welding

- Flash welding

2.1 Resistance spot welding

- The most common type of spot welding

- Uses two electrodes to apply pressure and heat to the metal components

- Produces a strong, localized weld

2.2 Capacitor discharge spot welding

- Uses a capacitor to store electrical energy

- Discharges the energy through the metal components to create a weld

- Produces a fast, precise weld

2.3 Stud welding

- Used to attach studs to metal surfaces

- Uses an arc to melt the metal and create a weld

- Produces a strong, permanent bond

2.4 Projection welding

- Used to join metal components with raised projections

- The projections melt and form a weld

- Produces a strong, consistent weld

2.5 Flash welding

- Used to join metal components by heating them until they melt

- The molten metal is extruded from the joint, creating a strong weld

- Produces a large, strong weld

3. What are the key factors that affect the quality of a spot weld?

The key factors that affect the quality of a spot weld include:

- Proper alignment and fit of the components

- Adequate welding pressure

- Correct welding current

- Appropriate welding time

- Cleanliness of the metal surfaces

4. What are the potential hazards associated with spot welding?

The potential hazards associated with spot welding include:

- Electrical shock

- Arc flash

- Fumes and gases

- Noise

- Burns

5. What safety precautions should be taken when performing spot welding?

The safety precautions that should be taken when performing spot welding include:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a welding helmet

- Ensure that the work area is well-ventilated

- Do not touch the welding electrodes with bare skin

- Do not weld on wet or flammable surfaces

- Be aware of the potential hazards and take appropriate precautions

6. What are the different types of spot welding machines?

- Manual spot welding machines

- Semi-automatic spot welding machines

- Automatic spot welding machines

6.1 Manual spot welding machines

- Operated by hand

- Require the operator to manually position the components and initiate the welding process

- Ideal for small-batch production

6.2 Semi-automatic spot welding machines

- Controlled by a foot pedal or other device

- Allow the operator to focus on positioning the components

- Ideal for medium-batch production

6.3 Automatic spot welding machines

- Fully automated

- Programmed to perform specific welding sequences

- Ideal for high-volume production

7. What are the advantages of using a spot welding machine?

- Increased productivity

- Improved weld quality

- Reduced labor costs

- Enhanced safety

8. What are the challenges of using a spot welding machine?

- High initial investment cost

- Need for skilled operators

- Potential for downtime

- Safety hazards

9. What are the applications of spot welding?

- Automotive industry

- Aerospace industry

- Appliance industry

- Construction industry

- Electronic industry

10. What are the career opportunities for spot welders?

- Spot welder

- Welding supervisor

- Welding engineer

- Quality control inspector

- Sales representative

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spot Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spot Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spot Workers perform a wide range of duties in various industries, including manufacturing, construction, transportation, and hospitality. Here are some of the common key job responsibilities:

1. Manual Labor

Spot Workers typically perform manual labor tasks such as lifting, moving, and operating machinery. They may also need to assemble and pack products, clean and maintain equipment, or perform other labor-intensive tasks.

2. Material Handling

Spot Workers are often responsible for handling materials, including raw materials, finished products, and waste. They may need to load and unload trucks, operate forklifts, or move materials around a warehouse or production facility.

3. Assembly and Production

Spot Workers may perform assembly and production tasks, such as assembling products, operating machinery, or performing quality control checks. They may also need to assist with packaging and shipping products.

4. Maintenance and Repairs

Spot Workers may perform basic maintenance and repairs, such as cleaning and lubricating equipment, replacing parts, or performing minor repairs. They may also need to help with general maintenance and upkeep of facilities.

5. Customer Service

Spot Workers may interact with customers, providing information, assistance, or resolving any issues. They may also need to help with customer service tasks such as answering phones, taking orders, or processing payments.

Interview Tips

Here are some interview tips to help Spot Worker candidates ace their interviews:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific Spot Worker position you’re interested in. This will help you understand the company’s culture, values, and the skills and experience they’re looking for in a candidate.

2. Prepare for Common Interview Questions

There are many common interview questions that Spot Worker candidates can expect, such as:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “Describe your experience in manual labor.”

- “How do you handle working in a fast-paced environment?”

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience that make you a qualified candidate for the Spot Worker position. Emphasize your ability to perform manual labor, handle materials, and work in a fast-paced environment. Provide specific examples from your previous work experience to demonstrate your skills.

4. Be Enthusiastic and Positive

Spot Workers are often required to work in demanding and often physically challenging environments. Employers are looking for candidates who are enthusiastic, positive, and motivated to work hard. Be sure to show the interviewer that you’re passionate about the work and that you’re eager to contribute to the team.

5. Follow Up After the Interview

After the interview, be sure to follow up with the interviewer. Send a thank-you note and reiterate your interest in the position. You may also want to inquire about the next steps in the hiring process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spot Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.