Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spray Drier Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

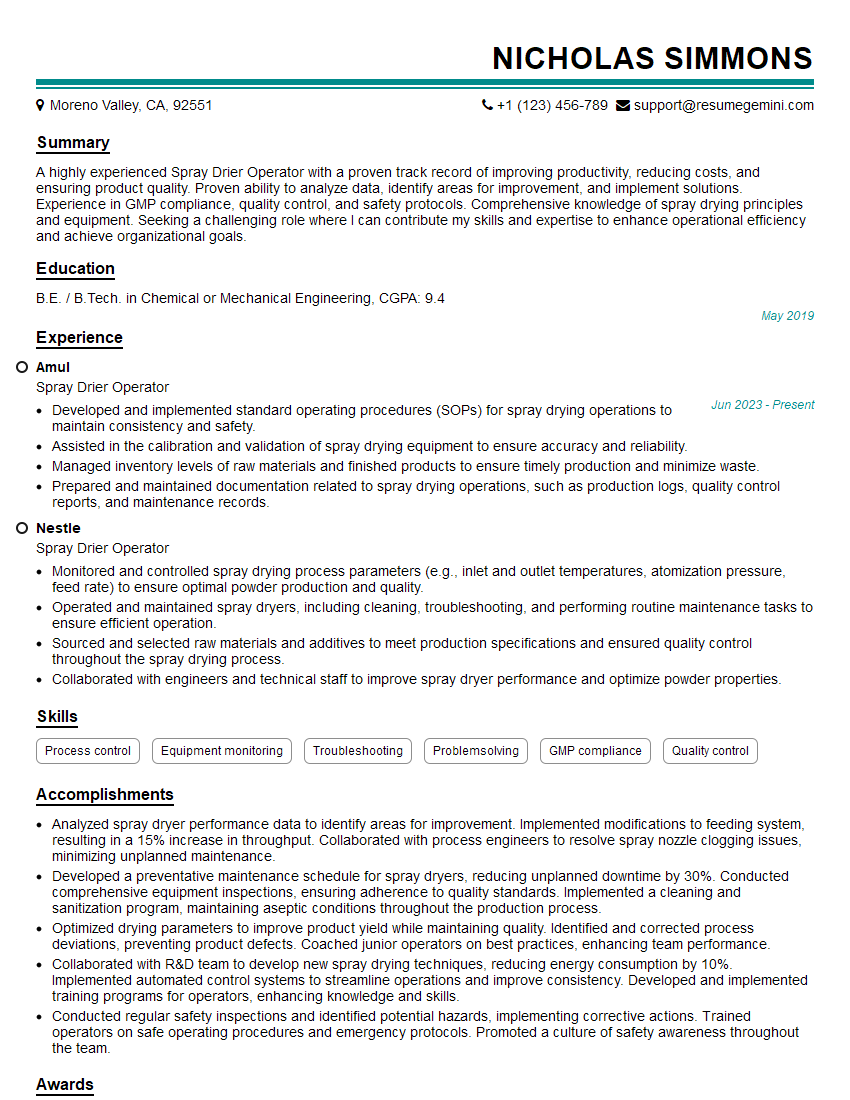

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spray Drier Operator

1. Explain the different types of spray dryers and their applications?

- Centrifugal spray dryers: Ideal for producing fine powders from liquids and slurries. Used in pharmaceutical, food, and chemical industries.

- Pneumatic spray dryers: Used when higher temperatures are needed to remove moisture quickly. Suitable for heat-sensitive materials.

- Rotary spray dryers: Suitable for drying large volumes of materials that are not heat-sensitive. Used in mining, agriculture, and chemical processing.

2. Describe the key operating parameters of a spray dryer and how they affect the product quality?

Feed concentration

- Higher concentration: Produces larger particles.

- Lower concentration: Produces smaller particles.

Inlet and outlet temperatures

- Higher inlet temperature: Faster drying, but can damage heat-sensitive materials.

- Lower outlet temperature: Slower drying, but preserves product quality.

Atomization rate

- Higher rate: Produces smaller particles.

- Lower rate: Produces larger particles.

3. How do you troubleshoot common problems encountered during spray drying and mitigate them?

- Caking: Increase atomization rate and improve air distribution.

- Sticking: Lower feed concentration or adjust drying temperature.

- Undissolved particles: Check feed preparation and filtration.

- High moisture content: Increase drying temperature or decrease feed rate.

- Low yield: Check for leaks or blockages in the system.

4. Explain the importance of preventive maintenance for spray dryers and describe the maintenance schedule you follow?

- Regular cleaning and inspection of nozzles, cyclones, and filters.

- Monitoring and calibration of sensors and instruments.

- Lubrication and alignment of rotating components.

- Scheduled overhauls to replace worn parts and ensure optimal performance.

5. How do you ensure the safety of the spray drying operation?

- Attend safety briefings and follow all safety protocols.

- Wear appropriate PPE, including gloves, goggles, and respiratory protection.

- Operate equipment within specified parameters and report any malfunctions immediately.

- Maintain a clean and organized work area to prevent tripping hazards.

6. How do you optimize the energy efficiency of a spray dryer?

- Use high-efficiency nozzles and fans.

- Insulate the drying chamber to reduce heat loss.

- Optimize feed concentration to minimize drying time.

- Install a heat recovery system to capture waste heat.

7. Describe your experience with different types of spray dryer control systems?

- PLC-based systems with HMI for monitoring and control.

- Advanced control algorithms for optimizing process parameters.

- Remote monitoring and data logging for quality control.

8. How do you prepare a spray dryer for startup and shutdown?

Startup

- Check and clean nozzles, cyclones, and filters.

- Start the fan and gradually increase the temperature.

- Introduce feed material slowly and adjust atomization rate.

Shutdown

- Stop feed material and continue drying to remove residual moisture.

- Turn off the fan and heater.

- Clean and inspect the dryer thoroughly.

9. How do you manage the disposal of wastewater and solid waste generated from spray drying?

- Wastewater: Neutralize and filter before disposal to comply with environmental regulations.

- Solid waste: Collect and dispose of in accordance with waste management protocols, considering the nature of the material.

10. How do you stay updated with the latest advancements and best practices in spray drying technology?

- Attend industry conferences and workshops.

- Read technical journals and online resources.

- Consult with equipment manufacturers and industry experts.

- Participate in training and development programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spray Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spray Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Spray Drier Operator is entrusted with the operation and maintenance of the spray drying system, which is a complex and critical piece of equipment in the production plant. The primary responsibilities include ensuring the smooth and efficient operation of the system, monitoring its performance, troubleshooting potential issues, and performing necessary maintenance to guarantee optimal functionality.

1. System Operation

The operator is responsible for initiating, monitoring, and controlling the spray drying process. They adjust and optimize process parameters such as feed rate, atomizer pressure, and drying temperature to achieve the desired product quality.

- Monitor and adjust operating parameters based on process specifications and quality control requirements.

- Operate and maintain the spray drying equipment, including the atomizer, cyclone separator, and bagging system.

2. System Monitoring

The operator continuously monitors the system’s performance and collects data to ensure it operates within specified limits. They identify and troubleshoot any deviations from standard operating procedures and take corrective actions to maintain optimal productivity.

- Monitor and record process data, such as feed flow rate, drying temperature, and product moisture content.

- Identify and troubleshoot system malfunctions, such as blockages, leaks, and temperature deviations.

3. Maintenance and Cleaning

The operator performs routine maintenance and cleaning tasks to ensure the system’s longevity and reliability. They conduct daily inspections, lubricate components, and replace worn or damaged parts as needed.

- Perform routine maintenance tasks, such as cleaning and lubricating the equipment.

- Replace worn or damaged parts, such as gaskets, filters, and spray nozzles.

4. Quality Control

The operator plays a crucial role in maintaining product quality by monitoring and controlling the drying process. They collect samples and conduct quality tests to ensure the final product meets specifications.

- Collect and analyze product samples to ensure compliance with quality standards.

- Implement corrective actions based on quality control results.

Interview Tips

Preparing for an interview for a Spray Drier Operator position requires thorough research and a strategic approach. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Before the interview, candidates should thoroughly research the target company and the industry in which they operate. They should familiarize themselves with the company’s products, services, mission, and values. Knowledge of the industry’s trends and best practices will demonstrate a genuine interest in the field.

- Visit the company’s website to gather information about its history, operations, and financial performance.

- Read industry publications and attend webinars to stay updated on the latest developments.

2. Highlight Relevant Skills and Experience

Candidates should carefully review the job description and identify the key skills and experience required for the role. They should prepare to articulate their proficiency in these areas with specific examples from their work history.

- Quantify accomplishments using specific metrics and data whenever possible.

- Use the STAR method (Situation, Task, Action, Result) to structure responses to behavioral questions.

3. Emphasize Safety and Quality Control

Safety and quality control are paramount in the operation of spray drying systems. Candidates should showcase their understanding of safety protocols, good manufacturing practices (GMPs), and quality assurance procedures.

- Provide examples of how they have implemented and maintained safety measures in previous roles.

- Discuss their knowledge of quality control techniques and their experience in ensuring product quality.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer demonstrates interest and engagement. Candidates should ask questions that explore the company’s culture, growth opportunities, and commitment to ongoing training and development.

- Inquire about the company’s investment in employee training and career advancement.

- Ask about the safety culture and the company’s track record in preventing accidents.

5. Practice and Seek Feedback

Practice is crucial for success in any interview. Candidates should conduct mock interviews with a friend, family member, or career counselor. Seeking feedback on their presentation, communication skills, and response to potential questions will help them refine their approach and boost their confidence.

- Record practice interviews to identify areas for improvement.

- Ask for constructive criticism and suggestions to enhance presentation and communication skills.

Next Step:

Now that you’re armed with the knowledge of Spray Drier Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Spray Drier Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini