Feeling lost in a sea of interview questions? Landed that dream interview for Spray Dry Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Spray Dry Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

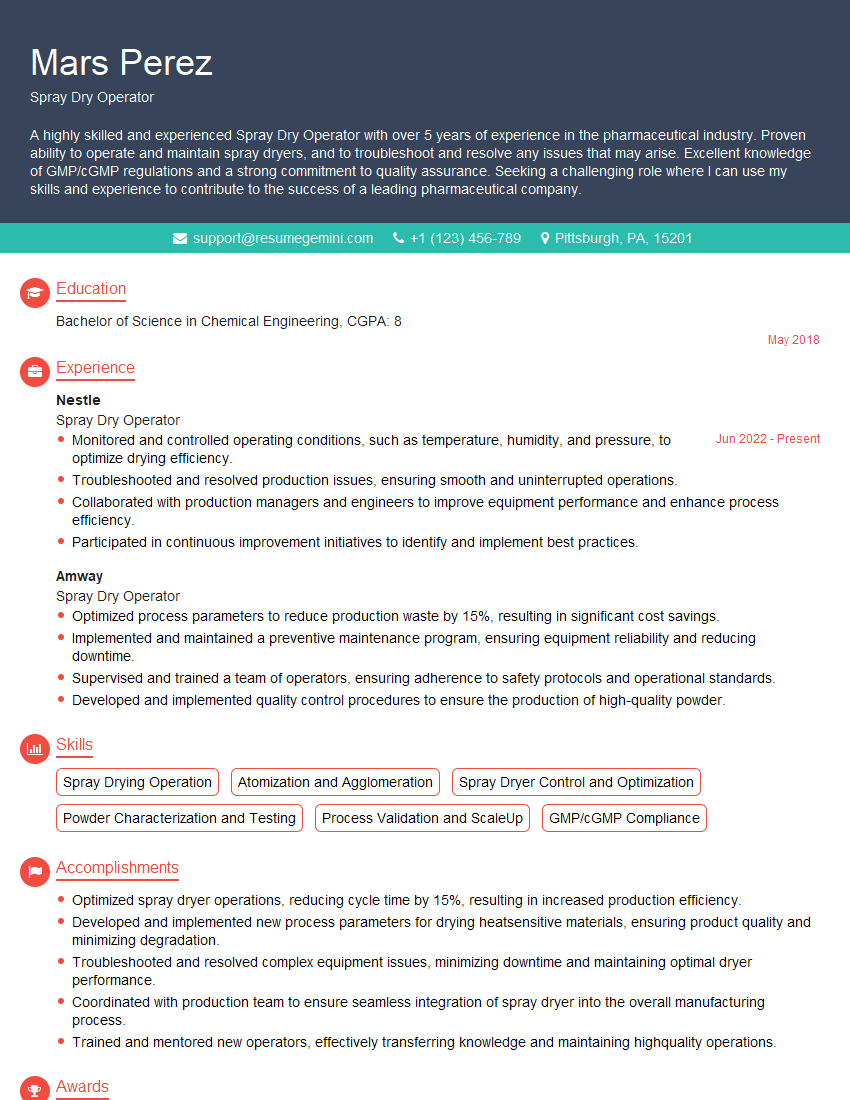

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spray Dry Operator

1. Describe the key responsibilities of a Spray Dry Operator.

- Operate and monitor spray drying equipment to produce dry powder from liquid feedstock.

- Ensure optimum operating conditions to achieve desired product quality and efficiency.

- Monitor and control process parameters, such as temperature, pressure, flow rates, and atomization.

- Maintain equipment, perform troubleshooting, and make necessary adjustments.

- Follow standard operating procedures (SOPs) and adhere to safety protocols.

2. Explain the different types of spray dryers and their applications.

- Centrifugal Atomizer Dryers: Produce fine powders with high surface area, suitable for pharmaceuticals and food products.

- Pressure Nozzle Dryers: Used for larger particle sizes, ideal for ceramics and chemicals.

- Two-Fluid Nozzles Dryers: Combine gas and liquid to create an even spray, resulting in controlled particle size distribution.

- Rotary Atomizer Dryers: Utilize a rotating disk to atomize feedstock, producing spherical particles.

3. How do you ensure product quality during spray drying operations?

- Monitor product characteristics, such as moisture content, particle size, and flowability.

- Conduct regular quality checks and perform laboratory analysis to meet specifications.

- Control process conditions, such as inlet and outlet temperatures, to achieve desired product properties.

- Implement corrective actions to address any deviations from quality standards.

4. Describe the steps involved in troubleshooting common spray drying issues.

- Identify the issue and its potential causes.

- Check equipment settings, process parameters, and feedstock properties.

- Perform maintenance or calibration if necessary.

- Consult with engineers or technical experts for support.

- Document troubleshooting steps and findings for future reference.

5. How do you handle emergency situations in a spray drying operation?

- Follow established emergency procedures to ensure safety.

- Identify the source of the emergency and take immediate action to control the situation.

- Communicate with supervisors and relevant personnel.

- Document the incident and investigate the root cause to prevent future occurrences.

6. Explain the importance of preventive maintenance in spray drying equipment.

- Reduces downtime and increases equipment lifespan.

- Ensures efficient operation and product quality.

- Identifies potential issues and allows for timely repairs.

- Optimizes energy consumption and reduces production costs.

7. Describe the different methods of atomization used in spray drying.

- Pressure Nozzles: Uses high pressure to break up the liquid into droplets.

- Rotary Atomizers: Sprays the liquid through a spinning disk.

- Ultrasonic Atomizers: Generates high-frequency vibrations to create droplets.

8. Explain the factors that influence the particle size distribution of spray-dried products.

- Properties of the feedstock, such as viscosity and surface tension.

- Atomization method and operating parameters.

- Drying conditions, including temperature and drying time.

9. How do you ensure the safety of the spray drying process?

- Follow established safety protocols and wear appropriate personal protective equipment (PPE).

- Monitor equipment for potential hazards, such as leaks or electrical malfunctions.

- Handle chemicals and feedstock properly.

- Maintain a clean and organized work area.

10. Describe your experience in performing root cause analysis on spray drying issues.

- Identify the problem and its potential causes.

- Gather data and evidence to support the investigation.

- Use analytical techniques to determine the root cause.

- Develop and implement corrective actions to prevent future occurrences.

11. Explain the principles of the spray drying process and how it is used in the pharmaceutical industry.

- Principles: Converts liquid feedstock into dry powder by atomizing the liquid and rapidly drying it.

- Pharmaceutical applications: Produces stable and easily dispersible drug formulations, enhances solubility, and improves drug delivery.

12. Describe the key performance indicators (KPIs) used to assess the efficiency of a spray drying operation.

- Product yield and quality.

- Drying efficiency and energy consumption.

- Equipment uptime and maintenance costs.

- Operator productivity and training.

13. How do you stay up-to-date on the latest advancements in spray drying technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Seek training and certification opportunities.

- Engage with suppliers and industry experts.

14. Describe the importance of understanding the feedstock properties in spray drying.

- Viscosity and surface tension affect atomization and particle formation.

- Solid content and composition influence drying efficiency and product quality.

- Feedstock characteristics guide process optimization and troubleshooting.

15. Explain the role of computational fluid dynamics (CFD) in spray drying process optimization.

- Models fluid flow patterns and particle behavior.

- Predicts temperature and moisture distribution.

- Optimizes atomization and drying conditions.

- Reduces experimental trial and error, saving time and resources.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spray Dry Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spray Dry Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spray Dry Operator is a pivotal role in the production process, tasked with ensuring the efficient and safe operation of spray drying equipment. The key job responsibilities encompass:

1. Operating Spray Drying Equipment

The operator is responsible for operating the spray dryer, ensuring it runs smoothly and efficiently. This involves:

- Monitoring and adjusting process parameters, such as feed rate, atomization pressure, and drying temperature

- Maintaining the dryer and its components, including filters, nozzles, and fans

2. Quality Control and Monitoring

The operator is responsible for monitoring the quality of the dried product and ensuring it meets specifications. This involves:

- Sampling and testing the dried product for moisture content, particle size, and other quality parameters

- Making adjustments to the process parameters based on the test results

3. Maintaining a Safe Work Environment

The operator is responsible for maintaining a safe and clean work environment. This involves:

- Following established safety procedures and protocols

- Using appropriate personal protective equipment

- Keeping the work area clean and organized

4. Troubleshooting and Problem-Solving

The operator may encounter technical issues or problems during the drying process. The operator is responsible for troubleshooting and solving these problems effectively and efficiently. This involves:

- Identifying the root cause of the problem

- Implementing appropriate corrective measures

- Documenting the problem and resolution for future reference

Interview Tips

To ace the interview for a Spray Dry Operator position, it’s crucial to prepare thoroughly and showcase your skills and knowledge. Here are some tips:

1. Research the Company and Position

Research the company’s background, industry, and product line. Read the job description carefully to understand the specific requirements and responsibilities of the Spray Dry Operator role.

- Highlight your experience in operating and maintaining spray drying equipment, including any specific models or brands you’ve worked with.

2. Emphasize Quality Control and Problem-Solving Skills

The ability to ensure product quality and troubleshoot problems is essential for a Spray Dry Operator. Emphasize your skills in sampling, testing, and making adjustments to process parameters.

- Share examples of how you have identified and resolved issues in previous roles, demonstrating your analytical and problem-solving abilities.

3. Highlight Safety and Compliance Knowledge

Safety and compliance are paramount in a production environment. Demonstrate your understanding of safety procedures and regulations relevant to spray drying operations.

- Provide examples of how you have implemented and enforced safety measures, ensuring a safe and compliant work area.

4. Prepare for Common Interview Questions

Research common interview questions for Spray Dry Operator positions. Prepare specific answers that highlight your relevant skills and experience.

- Some common questions include:

- Tell me about your experience with spray drying equipment.

- How do you ensure product quality and consistency?

- Describe a time when you had to troubleshoot a problem with the spray dryer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spray Dry Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!