Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spray Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

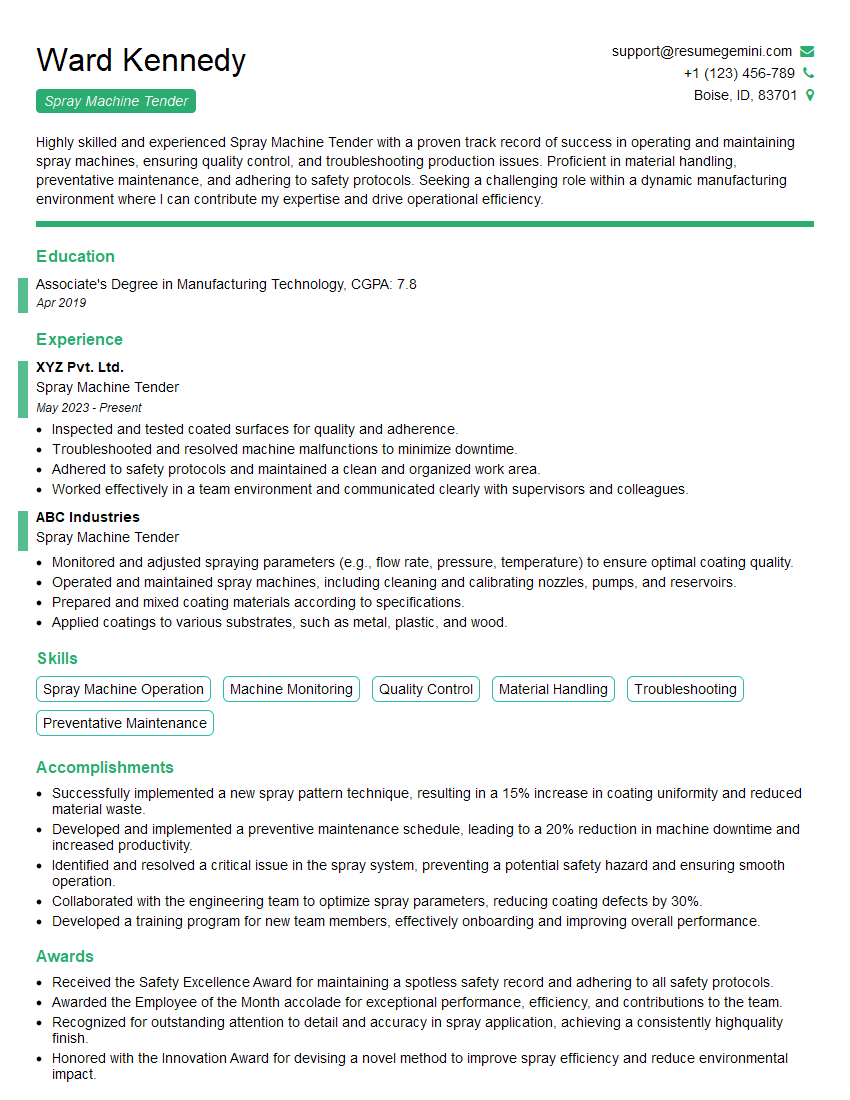

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spray Machine Tender

1. What are the different types of spray machines and their applications?

There are several types of spray machines, each designed for specific applications:

- Airless Sprayers: These machines use high-pressure air to atomize the paint and project it onto the surface. They are commonly used for industrial applications, heavy-duty painting, and large-scale projects.

- High-Volume Low-Pressure (HVLP) Sprayers: HVLP sprayers utilize a high volume of air at a lower pressure than airless sprayers. They produce a finer finish and are suitable for smaller projects, automotive painting, and detailed work.

- Low-Volume Low-Pressure (LVLP) Sprayers: LVLP sprayers use a low volume of air at a low pressure. They offer excellent control and precision, making them ideal for fine finishing, furniture painting, and delicate surfaces.

- Electrostatic Sprayers: Electrostatic sprayers impart an electrical charge to the paint particles, which then attract to the grounded surface. This technology reduces overspray and provides an even, high-quality finish.

- Air-Assisted Airless Sprayers: Air-assisted airless sprayers combine the principles of both airless and air spraying, allowing for greater control and versatility. They are often used in industrial and commercial painting.

2. Describe the process of preparing a spray machine for operation.

Safety Precautions

- Wear appropriate personal protective equipment (PPE) such as gloves, eye protection, and a respirator.

- Ensure the work area is well-ventilated.

Setup

- Inspect the spray machine and ensure it is in good working order.

- Connect the air supply to an appropriate pressure source.

- Fill the paint container with the desired material.

- Prime the pump and adjust the pressure settings according to the paint manufacturer’s specifications.

- Adjust the spray nozzle for the desired spray pattern and flow rate.

3. How do you troubleshoot common spray machine problems?

- Clogged Nozzle: Clean the nozzle with a solvent or replace it if necessary.

- Insufficient Pressure: Check the air supply and adjust the pressure settings.

- Spitting or Surging: Adjust the paint viscosity or check the pump for air bubbles.

- Uneven Spray Pattern: Inspect the nozzle for damage or adjust the spray angle.

- Excessive Overspray: Adjust the air pressure or nozzle settings, or use a finer spray tip.

4. What maintenance procedures are required for spray machines?

- Regular Cleaning: Clean the machine thoroughly after each use to prevent paint buildup and clogs.

- Lubrication: Lubricate moving parts according to the manufacturer’s instructions.

- Filter Replacement: Replace filters regularly to maintain optimal performance and prevent contamination.

- Inspection: Regularly inspect the machine for wear and tear, and replace worn components as necessary.

- Storage: Store the machine in a dry, well-ventilated area when not in use.

5. What are the safety precautions to consider when using a spray machine?

- Wear appropriate PPE, including gloves, eye protection, a respirator, and coveralls.

- Ensure adequate ventilation in the work area.

- Handle paints and solvents carefully, following manufacturer’s instructions.

- Never point the spray gun at anyone or yourself.

- Keep the spray area clear of flammable materials.

- Inspect the equipment before each use and report any defects immediately.

- Follow proper grounding procedures to prevent static electricity buildup.

6. What are the advantages of using a spray machine compared to traditional paint application methods?

- Efficiency: Spray machines can cover large areas quickly and efficiently, saving time and labor.

- Improved Finish: Spraying produces a smoother, more uniform finish than brushing or rolling.

- Reduced Material Waste: Spray machines minimize overspray and waste compared to other methods.

- Versatility: Spray machines can handle a wide range of paints and coatings, making them suitable for various applications.

- Safety: Spraying eliminates the need for ladders or scaffolding, reducing the risk of falls or injuries.

7. How do you calculate the amount of paint required for a specific project?

To calculate the amount of paint required, you can use the following formula:

Paint Required = Area to be Painted (Sq. Ft.) × Coverage Rate (Sq. Ft./Gal.) × Number of Coats

You can obtain the coverage rate information from the paint manufacturer’s specifications.

8. What techniques can you use to achieve a high-quality spray finish?

- Proper Preparation: Prepare the surface properly by cleaning, sanding, and masking off any areas not to be painted.

- Thinning the Paint: Adjust the paint viscosity to the manufacturer’s recommended spray consistency.

- Overlapping Strokes: Apply the paint in overlapping strokes, holding the spray gun perpendicular to the surface.

- Uniform Distance: Maintain a consistent distance between the spray gun and the surface to ensure even coverage.

- Multiple Coats: Apply multiple thin coats to avoid runs or sags and achieve the desired opacity.

9. How do you handle different types of paints and coatings?

- Latex Paints: Latex paints are water-based and easy to clean up. They are suitable for interior and exterior surfaces.

- Oil-Based Paints: Oil-based paints are more durable and resistant to moisture. They require mineral spirits or paint thinner for cleanup.

- Enamels: Enamels are high-gloss, durable coatings used for metal, wood, or plastic surfaces.

- Lacquer: Lacquer is a clear or pigmented finish that dries quickly. It is often used for wood and metal surfaces.

10. How do you stay updated on the latest advancements in spray machine technology?

- Attend industry trade shows.

- Read technical articles and publications.

- Consult with equipment manufacturers.

- Participate in online forums and discussion groups.

- Stay informed about new products and innovations through vendor websites.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spray Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spray Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Spray Machine Tender is a production worker responsible for operating and maintaining spray machines used in various industries such as manufacturing, painting, and finishing.

1. Operate Spray Machines

Tend and operate spray machines to apply coatings, sealants, or other materials to surfaces.

- Set up and adjust spray machines according to specifications.

- Monitor spray application processes and make necessary adjustments to ensure proper coverage and quality.

2. Maintain Equipment

Maintain and troubleshoot spray machines and related equipment to ensure efficient operation.

- Clean and inspect spray machines, nozzles, and hoses regularly.

- Perform minor repairs and maintenance tasks on spray equipment.

3. Prepare Materials

Prepare and mix coating materials and solutions according to prescribed formulas.

- Measure and weigh ingredients accurately.

- Mix and blend materials to achieve desired consistency and properties.

4. Quality Control

Inspect coated surfaces to ensure proper coverage, thickness, and quality.

- Identify and correct any defects or imperfections in the coating process.

- Maintain records of spray machine performance and quality control measures.

Interview Tips

Preparing thoroughly for an interview can increase your chances of success. Here are some tips and hacks to help you ace your Spray Machine Tender interview:

1. Research the Company and Role

Research the company’s industry, products, and culture to demonstrate your interest and understanding of the organization. Learn about the specific responsibilities of the Spray Machine Tender role and how it aligns with your skills and experience.

- Visit the company’s website, LinkedIn page, and industry publications.

- Review the job description thoroughly and identify keywords that you can incorporate into your answers.

2. Highlight Relevant Skills and Experience

Emphasize your experience operating and maintaining spray machines in a production environment. Showcase your ability to work independently and as part of a team, and highlight your attention to detail and quality control measures.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- Provide examples of how you have solved problems or improved processes in previous roles.

3. Demonstrate Knowledge of Coating Materials

Show your understanding of different coating materials, their properties, and application techniques. Discuss your experience preparing and mixing coating solutions, and explain how you ensure the quality and consistency of the finished product.

- Be familiar with common coating materials, such as paints, sealants, and adhesives.

- Explain how you determine the correct coating for different applications.

4. Prepare for Technical Questions

Expect technical questions about spray machine operation, maintenance, and troubleshooting. Be prepared to discuss your knowledge of spray equipment components, nozzles, and common problems that may arise during the spraying process.

- Review the basics of spray machine operation, such as pressure settings, flow rates, and nozzle selection.

- Practice troubleshooting common spray machine issues, such as clogs, leaks, and uneven spraying.

5. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive attitude throughout the interview. Demonstrate your enthusiasm for the role and show that you are eager to learn and contribute to the company. Remember to ask thoughtful questions and engage with the interviewer.

- Practice your answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Be prepared to answer questions about your career goals and how this opportunity aligns with your aspirations.

Next Step:

Now that you’re armed with the knowledge of Spray Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Spray Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini